Plate group transferring clamp

A technology of extremely group turnover fixtures and splints, which can be used in rigid containers, containers, packaging, etc., and can solve problems such as being unsuitable for mechanized operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

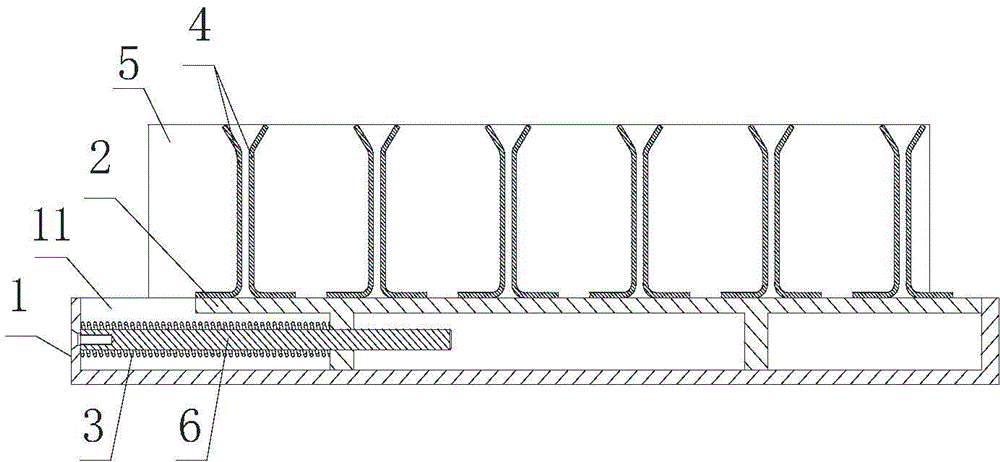

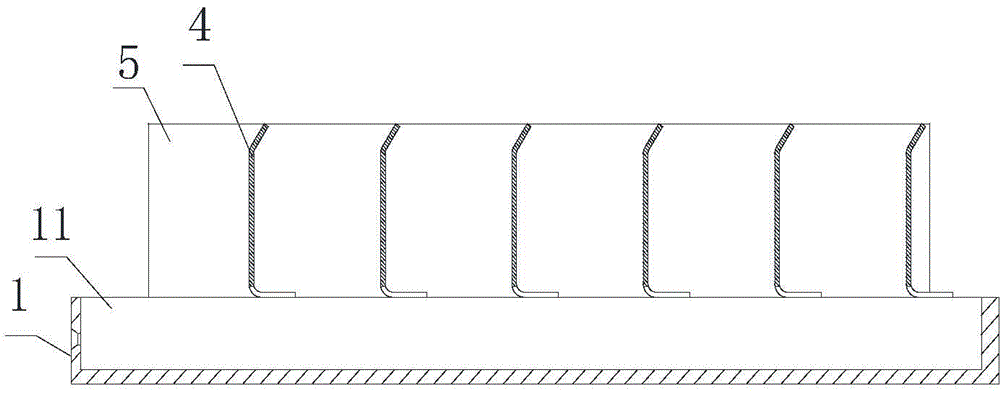

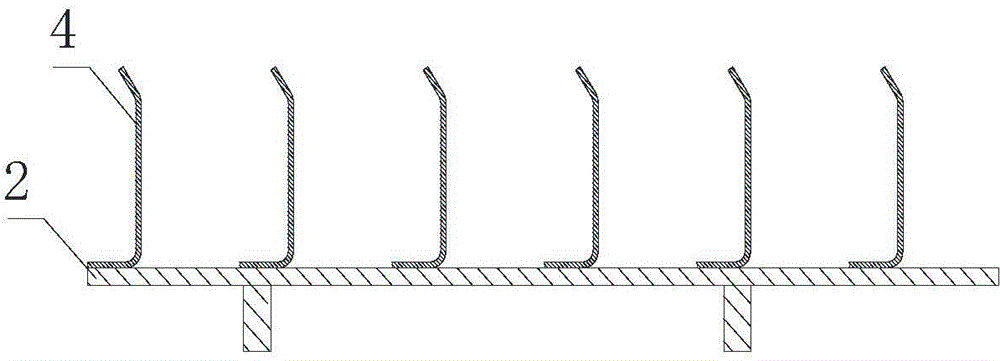

[0019] Such as Figures 1 to 5 As shown, the pole group turnover fixture includes a bottom plate 1 and a sliding plate 2 slidingly fitted with the bottom plate 1. A spring 3 is arranged between the bottom plate 1 and the sliding plate 2. In the direction in which the sliding plate 2 slides relative to the bottom plate 1 The spring 3 has an active force on the base plate 1 and the sliding plate 2. Several clamping plates 4 are arranged on the base plate 1 and the sliding plate 2, and the clamping plates 4 are arranged in a row in the direction in which the sliding plate 2 slides relative to the base plate 1. The splints 4 on the bottom plate 1 and the splints 4 on the sliding plate 2 are distributed at intervals, and the bottom plate 1 is provided with two baffles 5 arranged in parallel, and the baffles 5 are along the direction in which the sliding plate 2 slides relative to the bottom plate 1 Extending, the splint 4 is located between two baffles 5 . The top surface of the b...

Embodiment 2

[0022] Such as Figure 7 and 8 As shown, the structure is basically the same as that of Embodiment 1, the difference is that the bottom plate 1 is provided with a long hole 12 that runs through the upper and lower sides of the bottom plate 1, and the splint 4 on the bottom plate 1 is erected above the long hole 12. The sliding plate 2 is arranged in the elongated hole 12, the sliding plate 2 is positioned under the splint 4 on the base plate 1, the length of the elongated hole 12 is greater than the length of the sliding plate 2, and the splint 4 on the sliding plate 2 is set On the top surface of the sliding plate 2, in the width direction of the elongated hole 12, the two ends of the clamping plate 4 on the sliding plate 2 all exceed the scope of the elongated hole so that the clamping plate 4 on the sliding plate 2 is supported on the elongated hole 12, In fact, in this embodiment, the two degrees of freedom of the sliding plate 2 in the axial direction of the long hole ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com