Toothed scraper used for high-precision masonry construction and construction method of notched scraper

A tooth-shaped and masonry technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of unevenness, excessive thickness of mortar joints, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

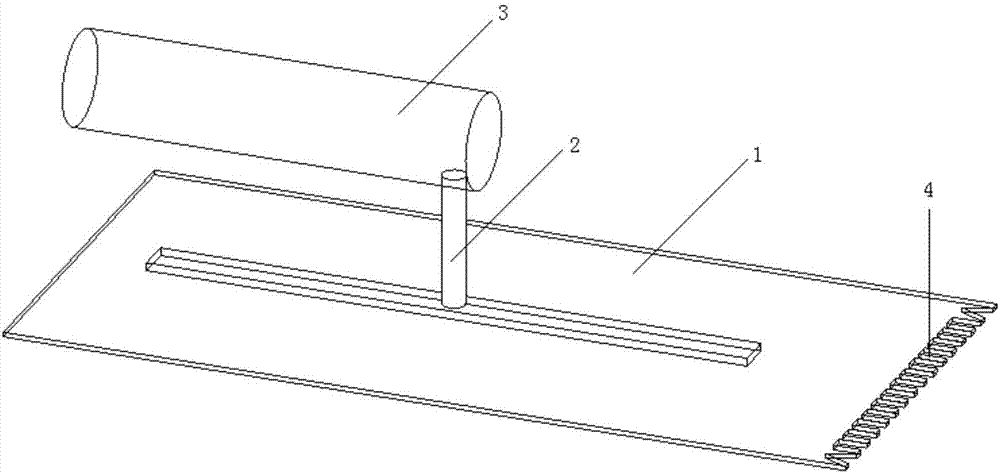

[0014] refer to figure 1 , a toothed scraper for high-precision masonry, including a toothed scraper 1, a connecting part 2, a handle 3, the front end of the toothed scraper 1 has a wave-shaped toothed part 4, and the toothed scraper The plate 1 is fixedly connected with the handle 3 through the connecting part 2; the toothed scraper 1 is a square steel plate, and the material of the square steel plate is a stainless steel plate, the size is 100mm×250mm×3mm, and the depth and width of the front end of the toothed scraper 1 are respectively 4mm; the toothed scraper 1 is set parallel to the handle 3, the connection part 2 is attached to the toothed scraper 1, and connects the handle 3 vertically; one end of the connection part 2 is welded and fixed on the toothed scraper 1, and the connection part 2 The other end is a pointed end; the handle 3 is made of wood and is cylindrical, and the pointed end of the connecting part 2 is inserted into the handle 3 so that the handle 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com