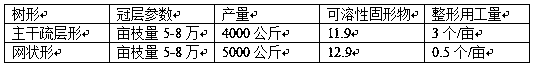

Patents

Literature

34results about How to "Suitable for mechanized operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical improvement conditioner suitable for coastal beach and strongly saline-alkaline land and application method thereof

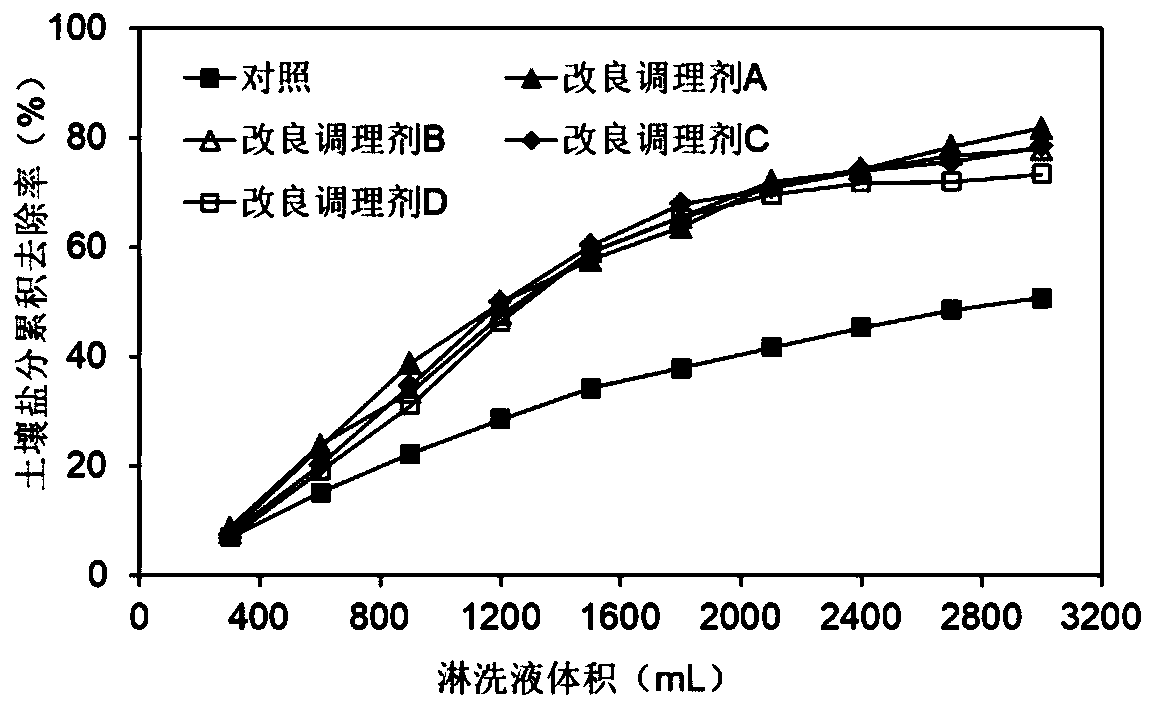

InactiveCN104276903AShorten the governance cycleIncreased rinse volumeOther chemical processesClimate change adaptationAlkali soilDry season

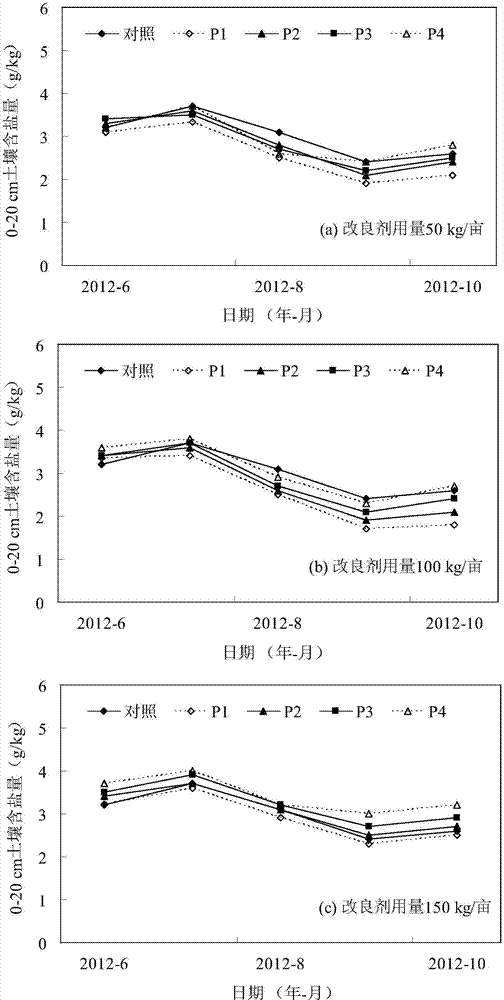

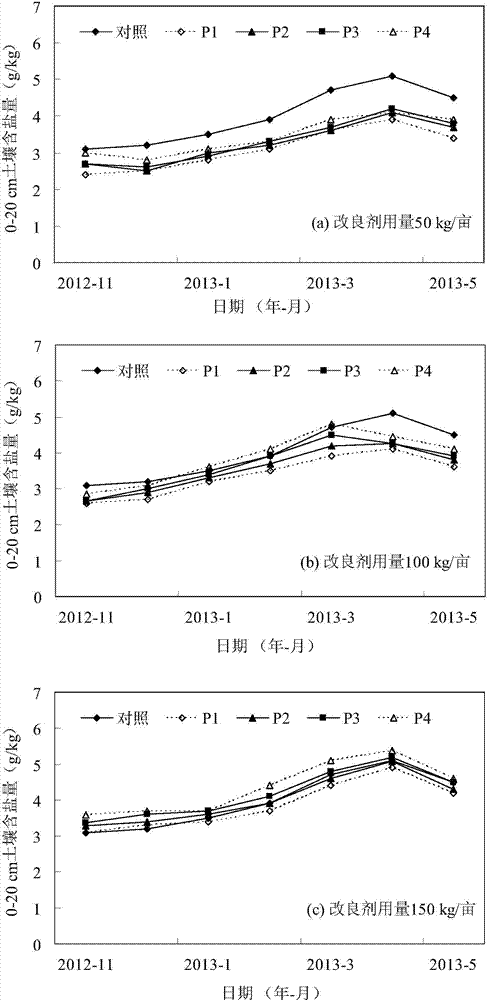

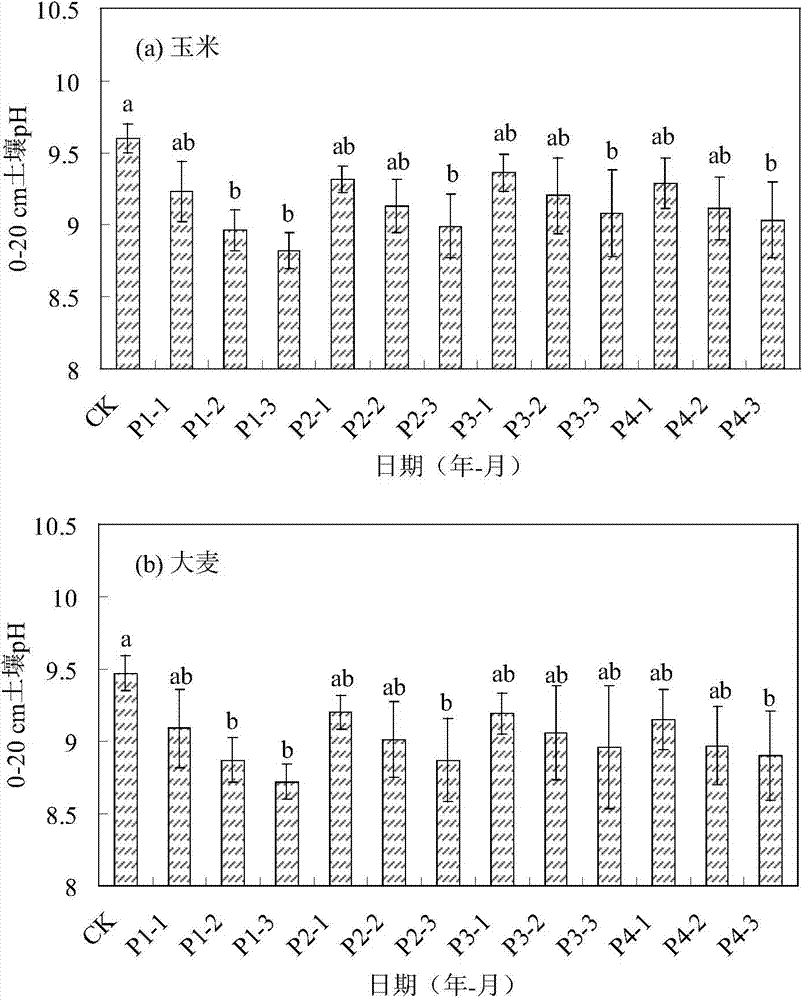

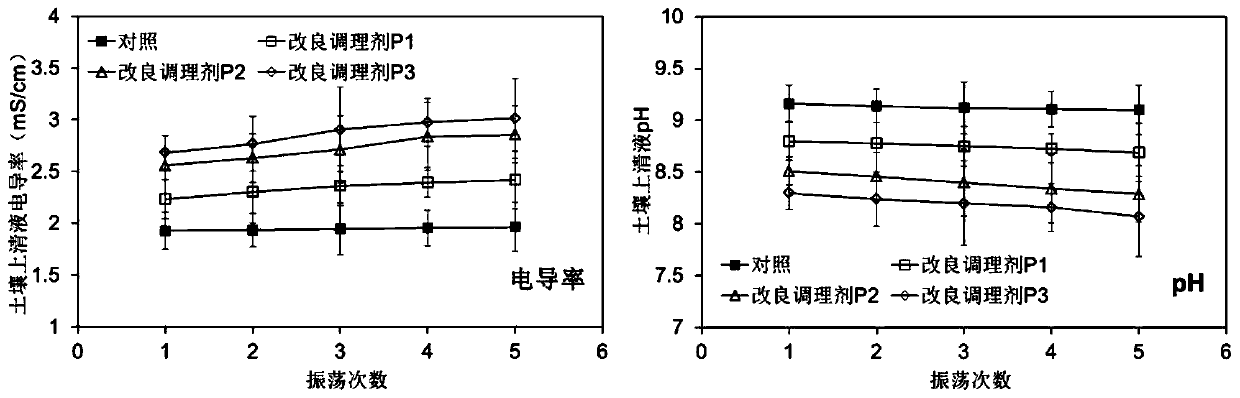

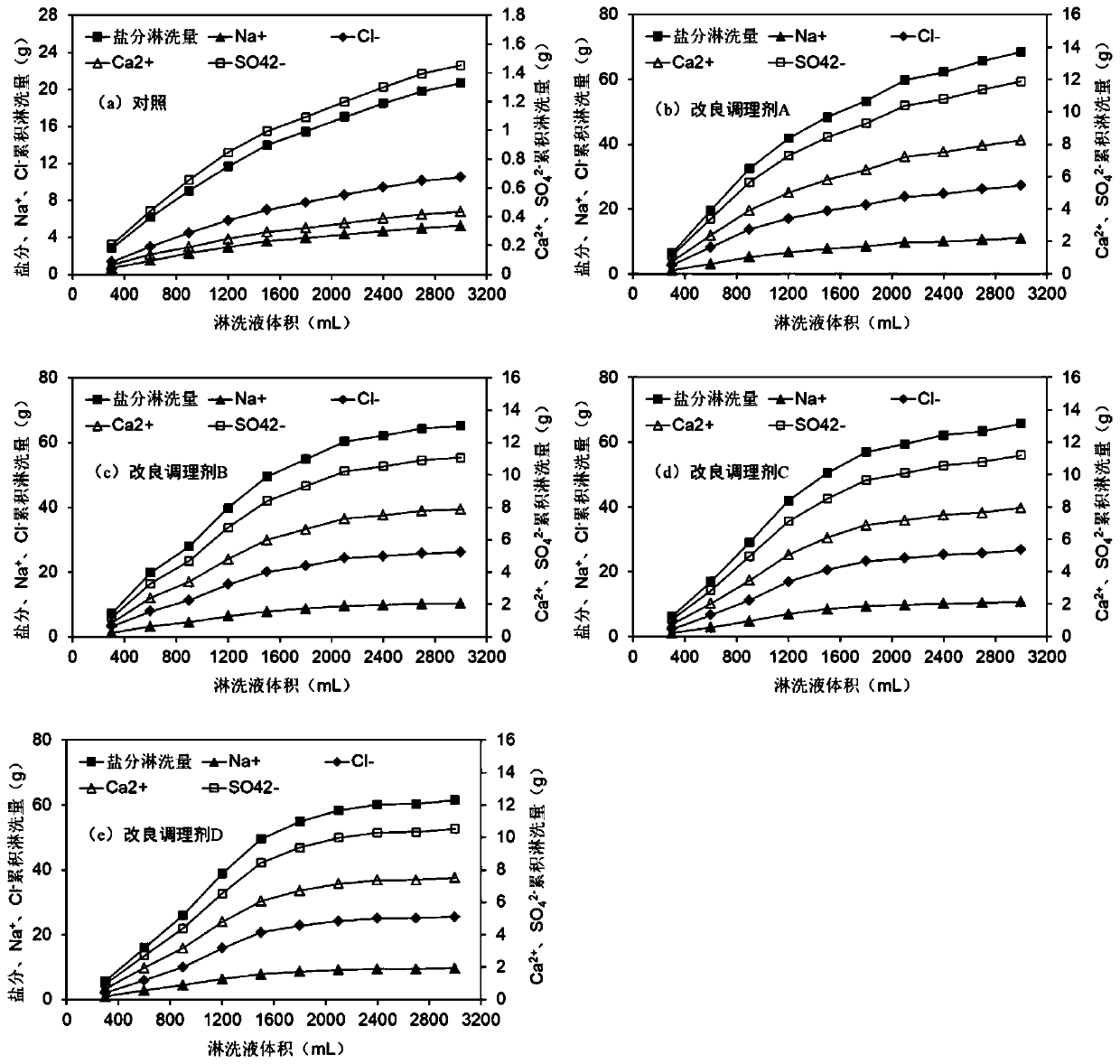

The invention relates to a chemical improvement conditioner suitable for a coastal beach and a strongly saline-alkaline land and an application method thereof. The chemical improvement conditioner comprises the following components in parts by weight: 50-70 parts of ardealite, 20-30 parts of humic acid, 5-10 parts of aluminum sulfate and 3-5 parts of potassium dihydrogen phosphate. The chemical improvement conditioner disclosed by the invention has the advantages of simple improver component and preparation process, clarity in principle, low cost and quick effect. The application method of the chemical improvement conditioner aiming at different planting modes and soil salinity conditions provides an optimized application mode of 'less use for dry farming, more use for water farming, less use for a dry season, more use for a rainy season, more use for double salt and less use for light salt' by comprehensively considering the plant modes, soil salt contents and the rainfall difference of different seasons, thereby improving the desalting and alkali-improving efficiency, farthest decreasing the residues of an improver in soil and realizing multiple purposes of salt leaching, soil improvement and fertility improvement of the coastal beach and the saline-alkaline land.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

Special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and preparation method and application of special rice fertilizer

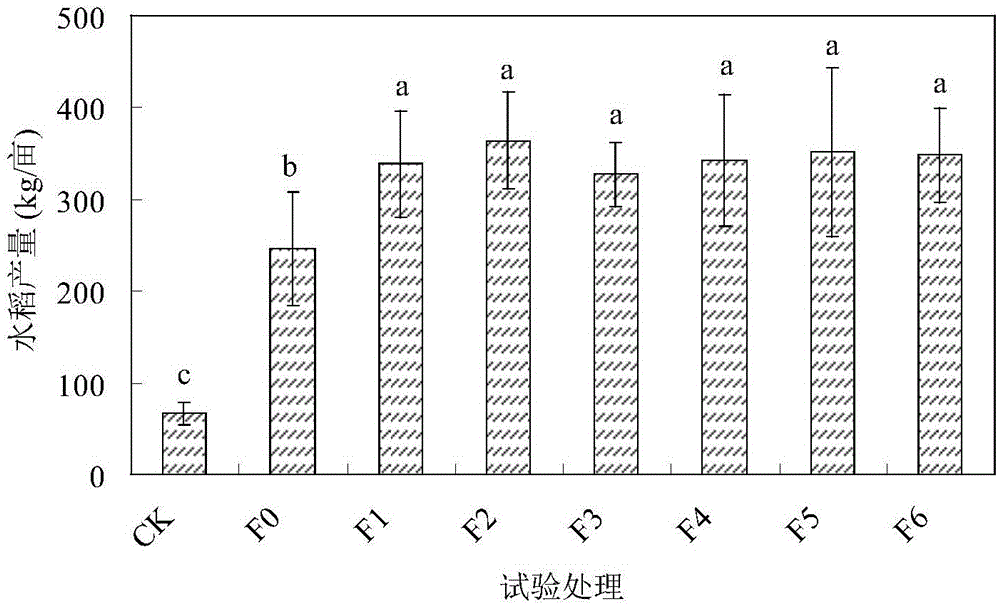

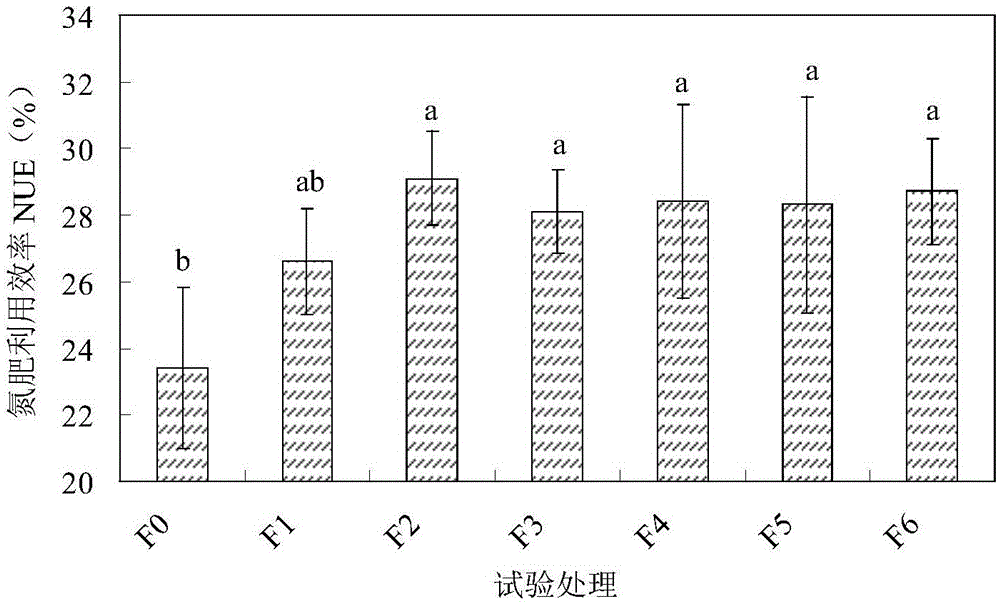

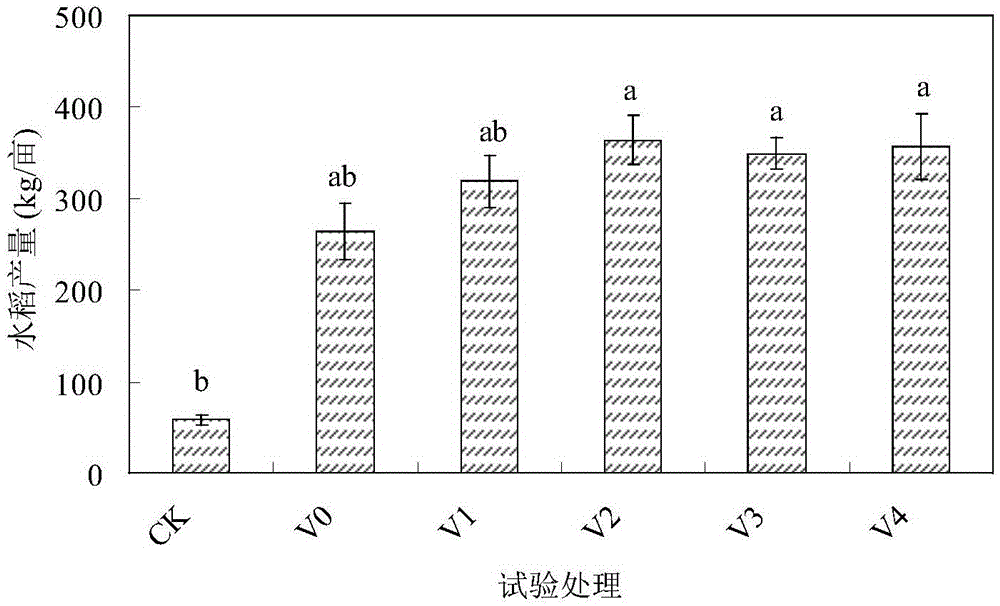

ActiveCN105111021AImprove physical and chemical propertiesImprove breathabilityFertilising methodsAgriculture gas emission reductionAlkali soilNitrification inhibitors

The invention discloses a special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and a preparation method and application of the special rice fertilizer. The special rice fertilizer comprises the following components in parts by mass: 35-40 parts of humic acid, 15-20 parts of fulvic acid, 20-25 parts of a composite fertilizer, 15-20 parts of a silicon calcium fertilizer, 1-1.5 parts of a urease inhibitor and 1-1.5 parts of a nitrification inhibitor. According to the invention, the application method combines soil culture, root system activation, crop nourishment and fertilizer efficiency improvement, so the rice fertilizer is low in cost, stable in effect, applicable to mechanical operation, not only applicable to coastal intertidal zones, but also applicable to rice planting in saline-alkali soil in north China or even northwest inland.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

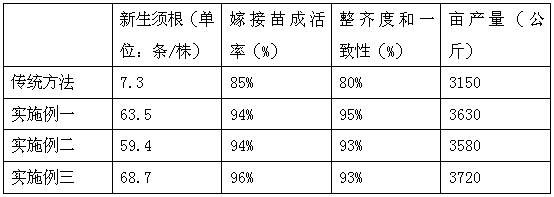

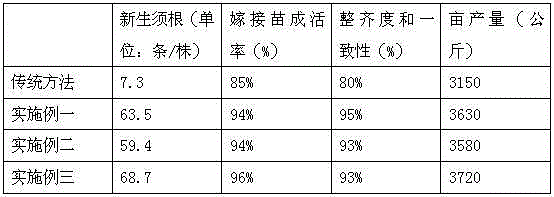

Spring thin skin melon grafting seedling raising method

The invention provides a spring thin skin melon grafting seedling raising method. The absorbing ability of a grafted seedling root system can be improved, the survival rate of grafted seedlings is improved, the uniformity and evenness of the grafted seedlings are guaranteed, and the mechanical operation of commercial seedlings is facilitated. The method mainly comprises the steps of variety selecting, sowing and seedling raising, grafting, grafted seedling managing and the like, wherein the melon variety is selected from moderate sugar I or abundant sugar I or Huang Zi Jin Yu, and the stock is selected from garden stock I or melon free stock or early maturing new tosa or black seed pumpkin. The double-root-cutting grafting method is adopted in the grafting step. In the seedling raising process, the pest control needs to conform to the principle of giving priority to the agricultural control, ecological control, physical control and biological control and complementing the chemical control.

Owner:ANQING JINDADI ECOLOGICAL AGRI DEVCO

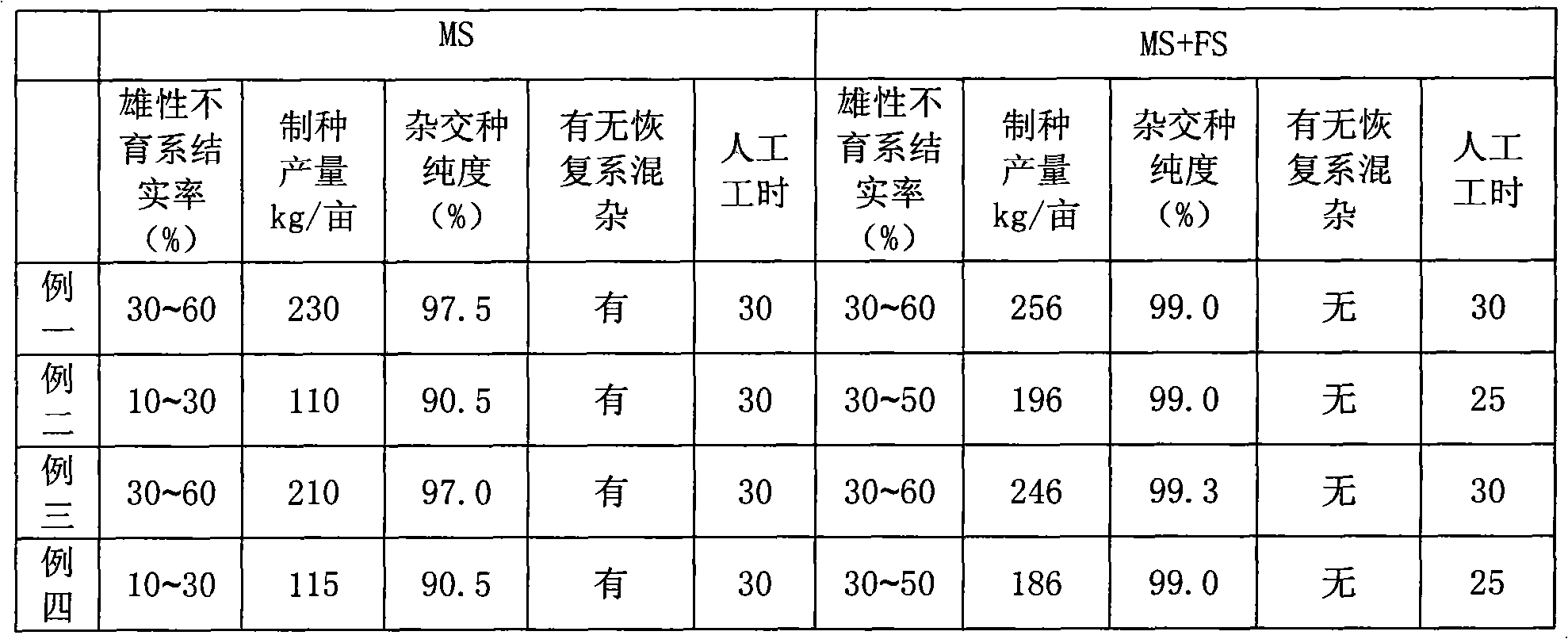

Method of female sterile gene FST for hybrid rice breeding

InactiveCN101658129AAvoid Mechanical MixingAvoid cleaning costsPlant peptidesGenetic engineeringAgricultural biotechnologyAgricultural science

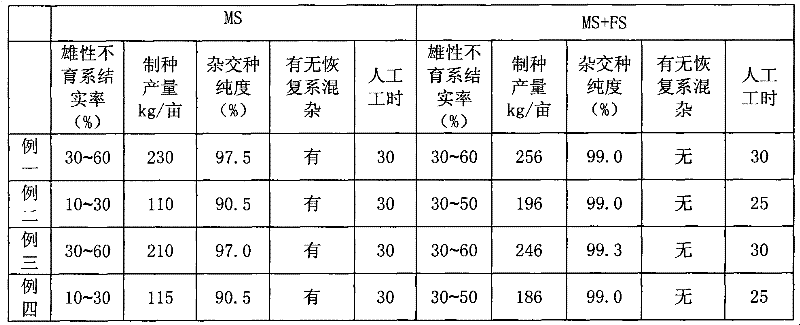

The invention relates to a method of female sterile gene FST for hybrid rice breeding, belonging to the breeding field in the technical field of agricultural biology. The technical scheme is as follows: male sterile lines are propagated according to a three-line or two-line method in a programming manner; the propagation of rice female sterile line can be completed by adopting asexual propagationmode of perennial roots, or two-purpose transgenic female sterile line expressed by culturing conditions leads the female fertility to be restored by artificial adjustment and control of FST gene expression so as to complete self propagation; and when in producing seeds, the male sterile system and the female sterile line are planted in the same filed, a pollen receptor is male sterile line, a pollen donor is female sterile line, the pollen of the female sterile line is conferred to the male sterile line and the harvested seed is hybrid seed. The method simultaneously utilizes male sterile (MS) and female sterile (FS) to construct seed producing modes of 'MS+FS', is suitable for mechanized operation, avoids mechanical mixing of a restorer and can accelerate the promotion and application process of hybrid rice.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Industrialized seedling culture method for Chinese onions

ActiveCN105557492AReduce the amount of seed usedShorten the breeding cycleGrowth substratesCulture mediaRoot systemTransplantation

The invention discloses an industrialized seedling culture method for Chinese onions. A seedling shed is set up according to a conventional method, a seedbed is arranged in the seedling shed, soil in the seedbed is leveled, and ridges are formed. The method specifically includes the following steps of firstly, laying gauze on the seedbed; secondly, filling a nursery seedling plate with a matrix; thirdly, pre-processing seeds before sowing; fourthly, sowing the seeds; fifthly, conducting film mulching; sixthly, managing the seedbed; seventhly, conducting disease control at the seedling stage; eighthly, improving the growth of roots and seedlings. When Chinese onion seedling culture is conducted through the seedling culture technology, the number of seeds which are used is small, seedling emergence is quick, seedlings are robust and resist diseases, root systems are developed, the environment can be artificially controlled for industrialized seedling culture, mechanical transplantation is facilitated, seedling recovery is quick after transplantation, seedling lands are saved, the seedling culture cost is greatly saved, and good development prospects are achieved.

Owner:山东沃华农业科技股份有限公司

Special spray-irrigation and drip-irrigation urea-ammonium nitrate (UAN) liquid fertilizer for crops

InactiveCN105399551AIncrease profitLow priceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDrip irrigation

The invention discloses a special spray-irrigation and drip-irrigation UAN liquid fertilizer for crops. The special spray-irrigation and drip-irrigation UAN liquid fertilizer is prepared from a urea-ammonium nitrate solution, industrial monoammonium phosphorate, potassium nitrate, potassium dihydrogen phosphate, EDTA manganese chelate, EDTA zinc chelate, borax, ammonium heptamolybdate, potassium fulvate, seaweed extract and water. The fertilizer has the advantages of a low price, comprehensive nutrients and a high utilization rate.

Owner:STANLEY AGRI GRP CO LTD

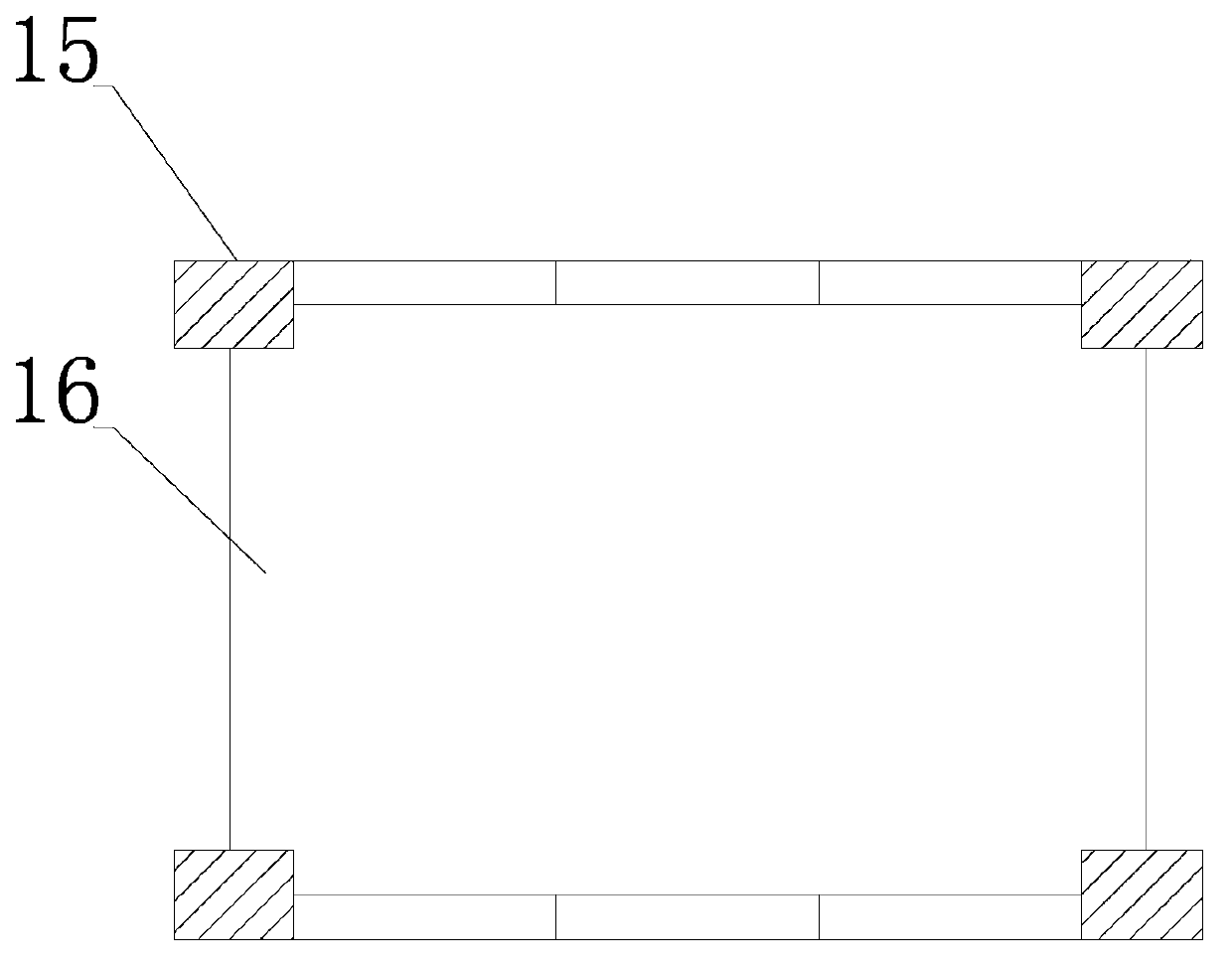

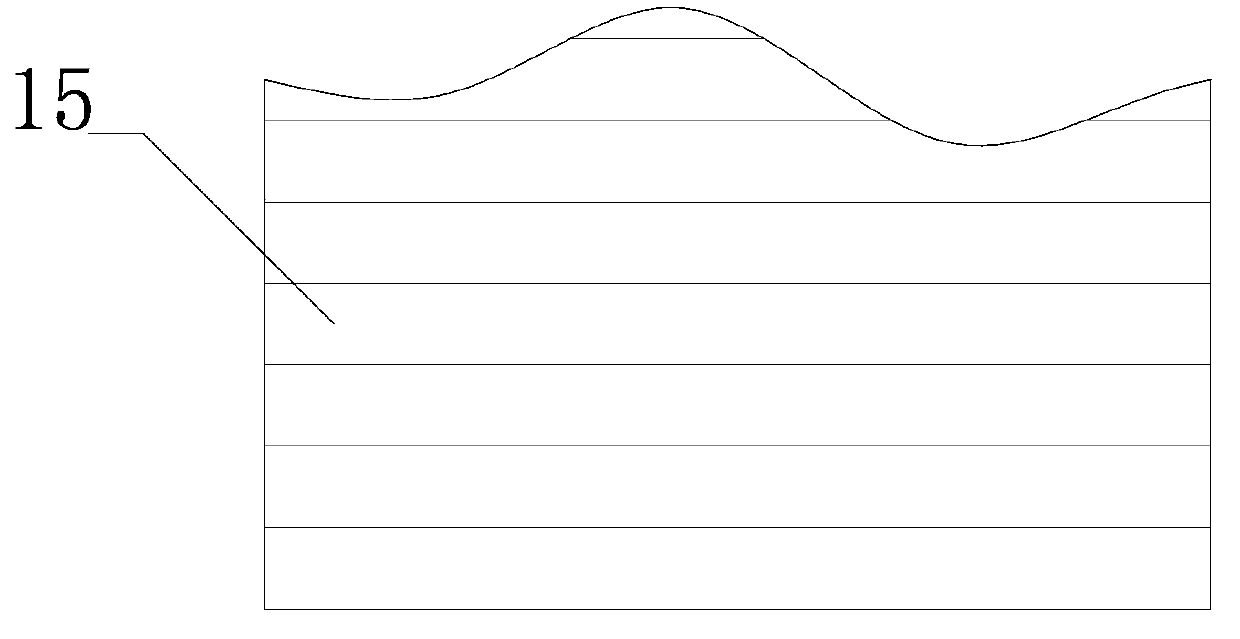

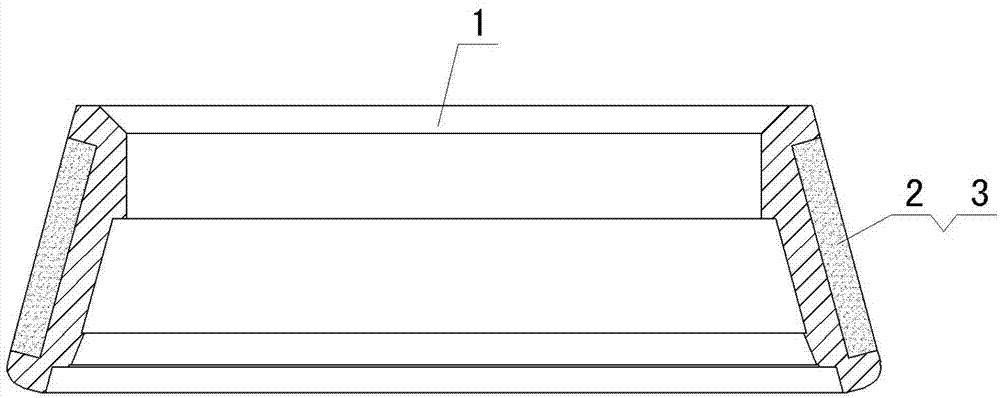

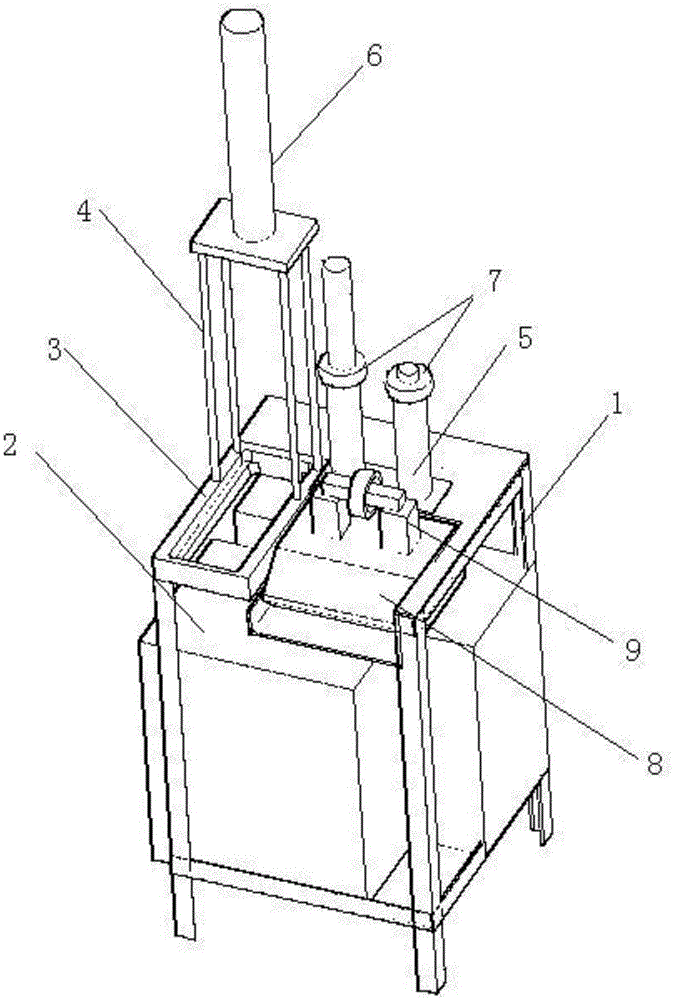

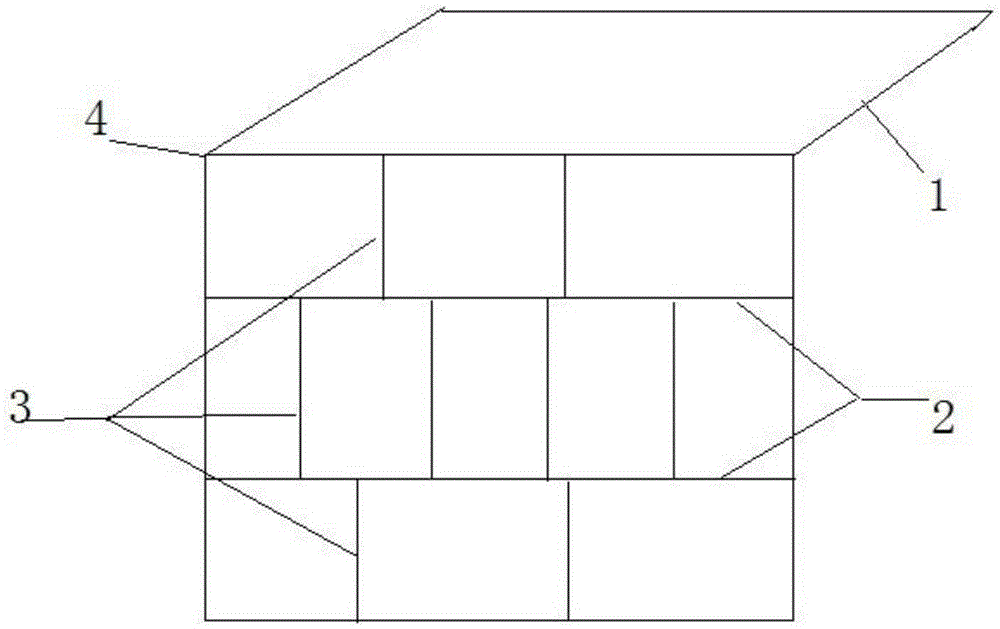

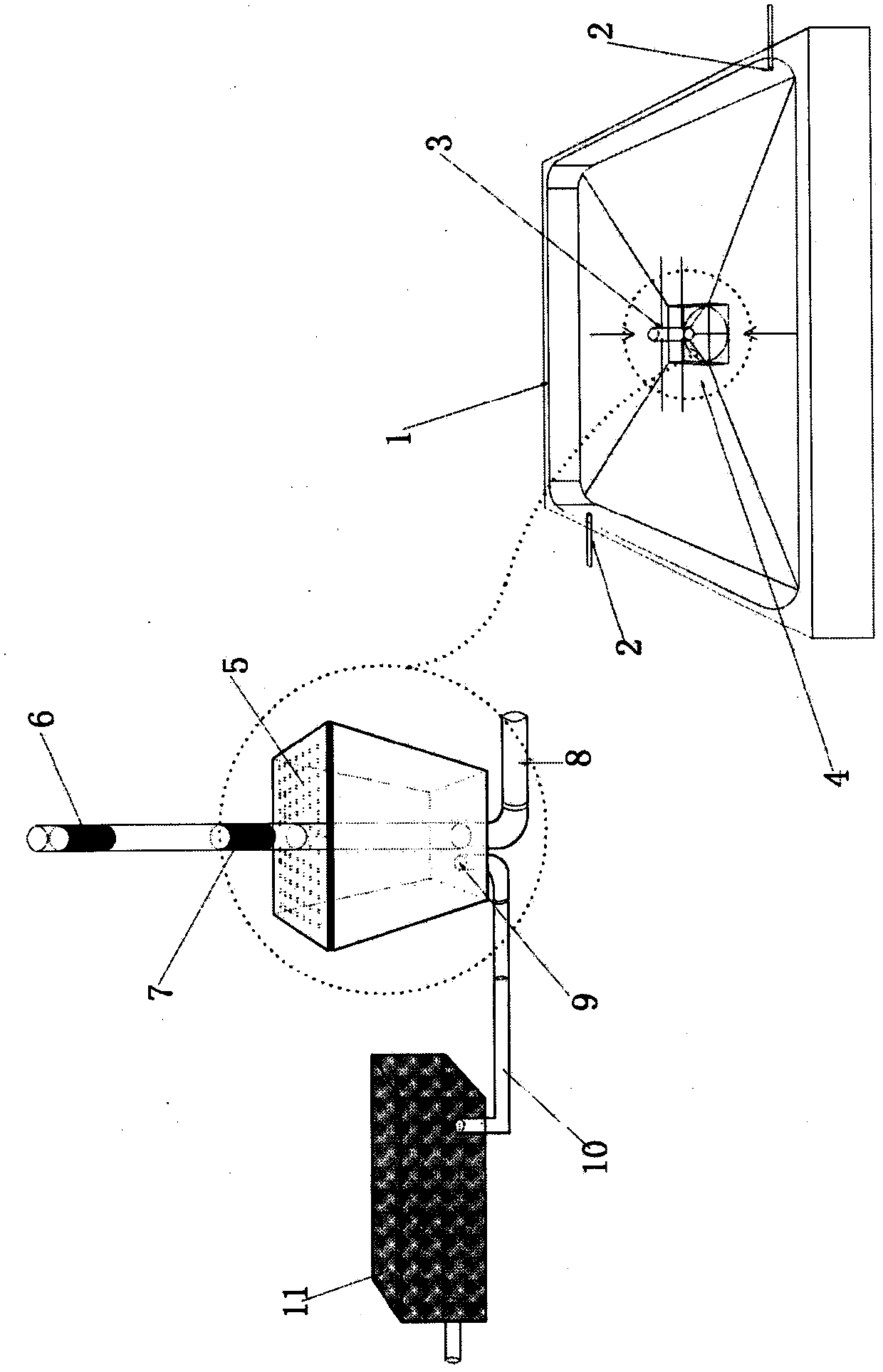

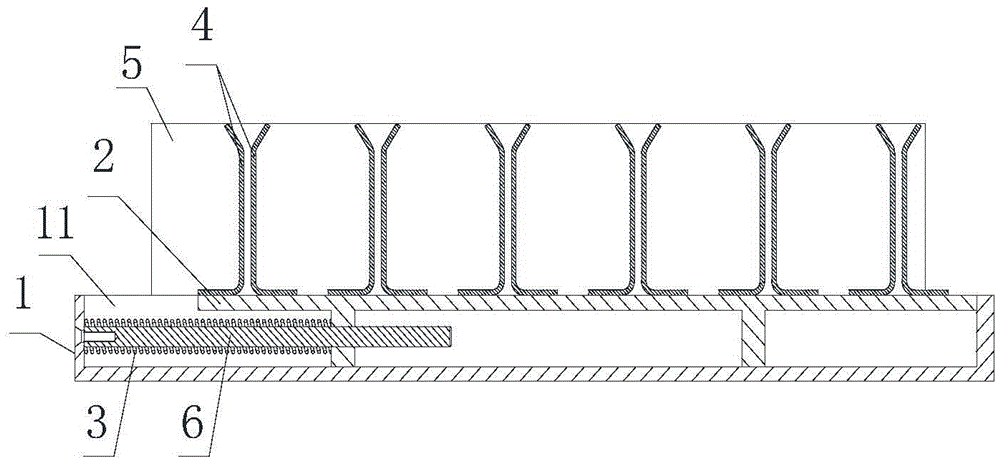

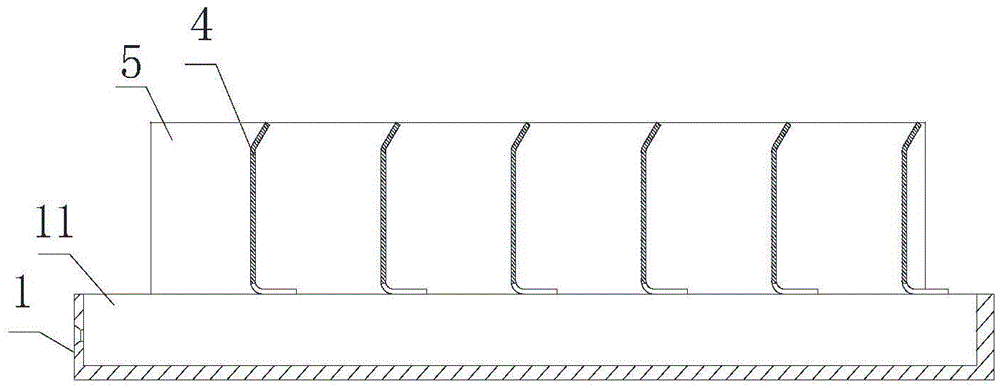

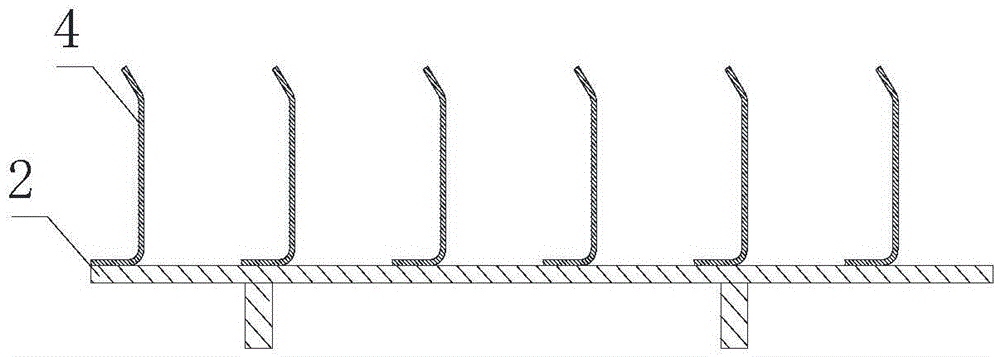

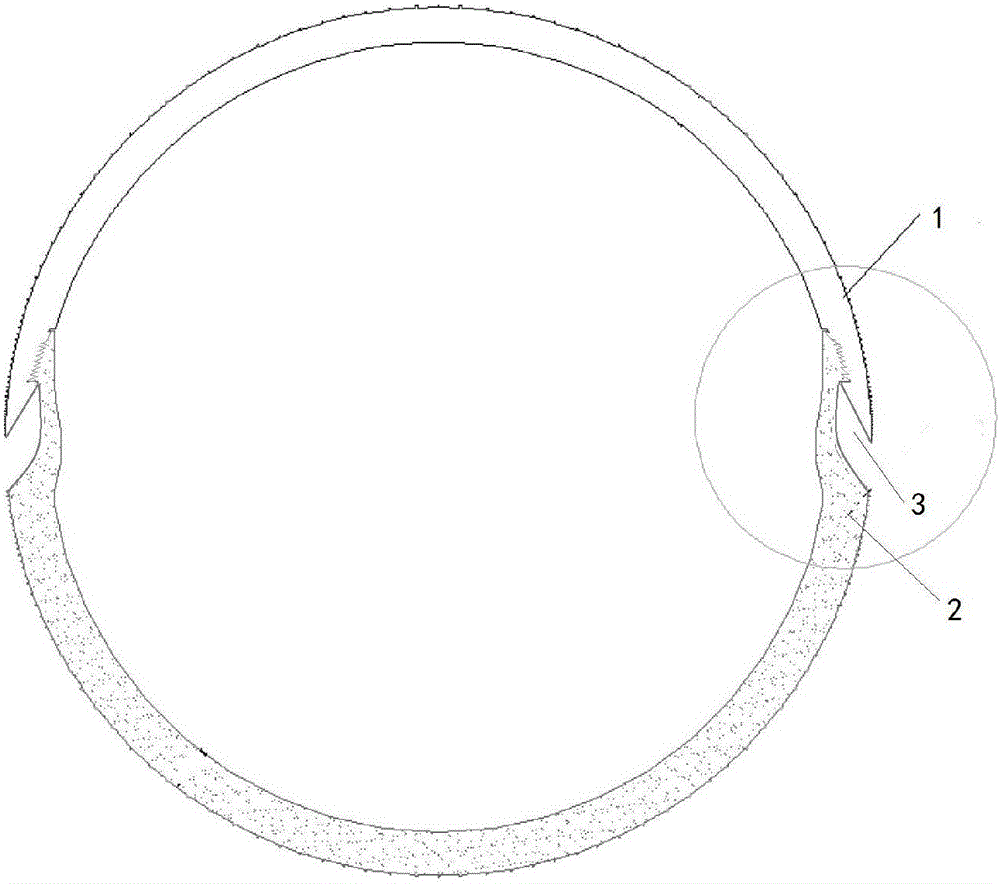

Support and support forming assembly device

The invention discloses a support and a support forming assembly device. The support comprises a positioning part, a wrapping part and a supporting part; the support forming assembly device comprises a preforming assembly, a forming assembling component and a translation lifting mechanism; the support forming assembly device is provided with a preforming station and a forming station; the preforming assembly is arranged on the preforming station which is located in the movement locus of the translation lifting mechanism; the forming station is also located in the movement locus of the translation lifting mechanism; and sterile brick arrays and the preformed support are combined together under the effect of the forming assembling component at the forming station. The support is simple in structure and convenient to produce; environment-friendly materials are selected for producing the support; when the support is used, the positioning and fixing effects are obvious; automatic forming and assembling are realized through a mechanical device; and compared with the positioning device in the prior art, the support has the advantages that recycling and reutilization are easy to realize, stacking and conveying are convenient, the supporting structural strength is large, and the support is suitable for mechanized operation.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

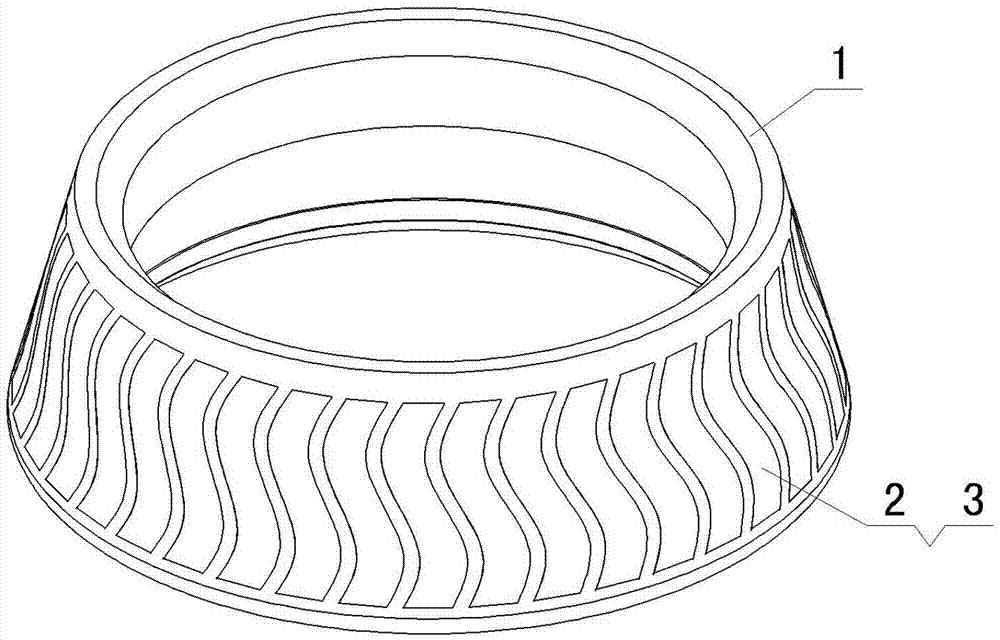

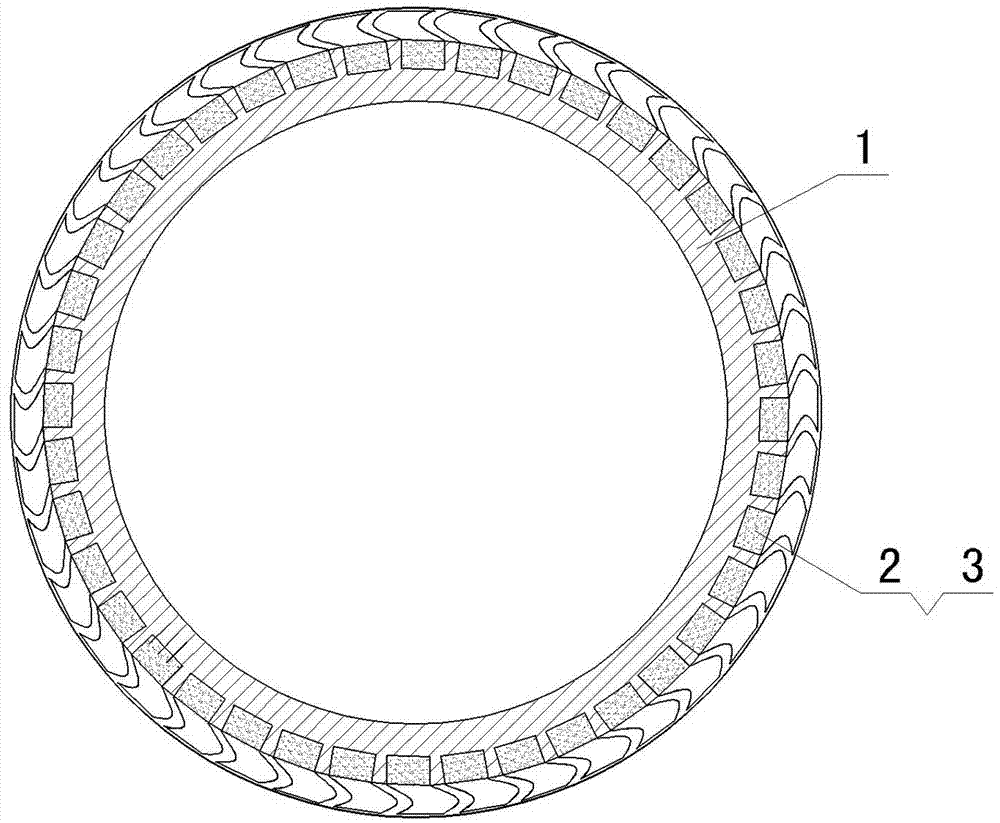

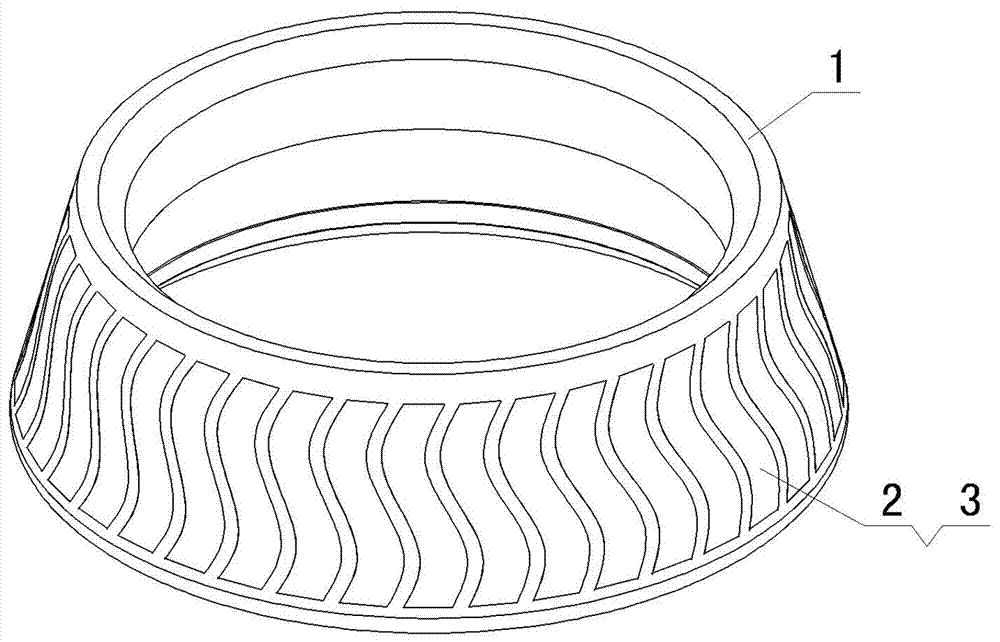

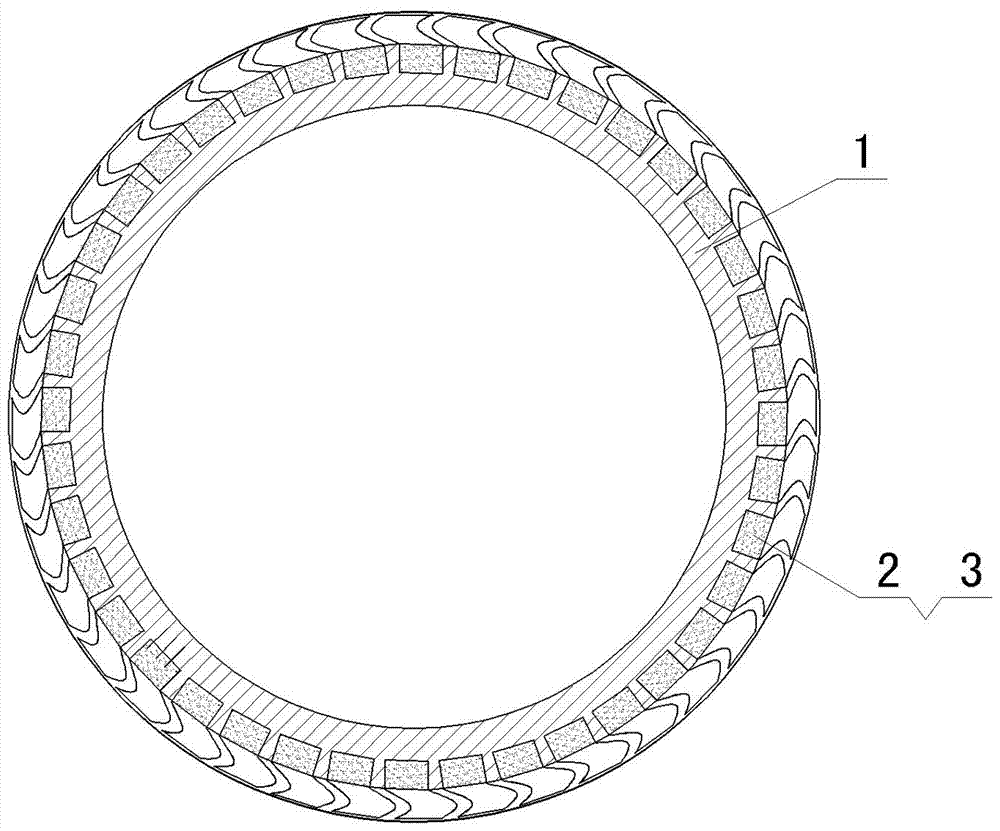

Composite material grinding roller and manufacturing method thereof

The invention relates to a composite material grinding roller and a manufacturing method thereof. The composite material grinding roller comprises a metal roller body and a plurality of wave-shaped composite bodies, wherein the wave-shaped composite bodies are embedded into a working plane of the metal roller body at equal intervals, are integrated with the metal roller body and are wave-shaped ceramic reinforcements or wave-shaped structural bodies composited from wave-shaped ceramic reinforcements and a metal substrate; the wave-shaped ceramic reinforcements are prepared by curing ceramic particles. The manufacturing method of the composite material grinding roller comprises the following steps: firstly designing and manufacturing the wave-shaped composite bodies of required sizes; then carrying out casting forming; and finally, cooling and processing, so as to obtain the composite material grinding roller. By virtue of design of the wave-shaped ceramic reinforcements, the composite material grinding roller has the structural characteristics that the ceramic reinforcements are easily and orderly arrayed in a mold cavity and are applicable to mechanical operation; the displacement and the malposition of each individual ceramic reinforcement in a casting process are effectively avoided; the whole displacement of the ceramic reinforcements in a working condition use process is avoided, and particularly, the composite material grinding roller is a secondarily poured large-sized composite material grinding roller.

Owner:GUANGDONG INST OF NEW MATERIALS

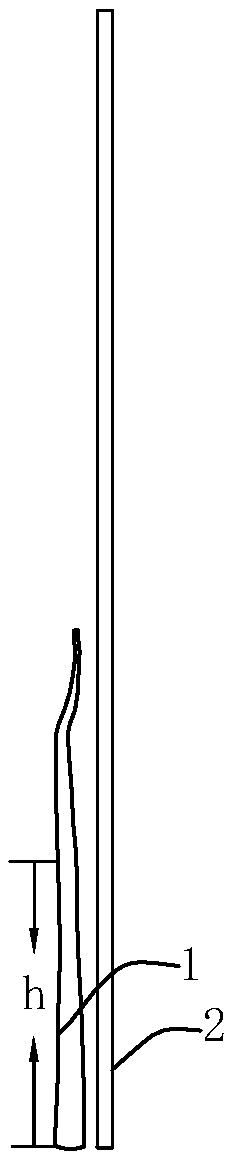

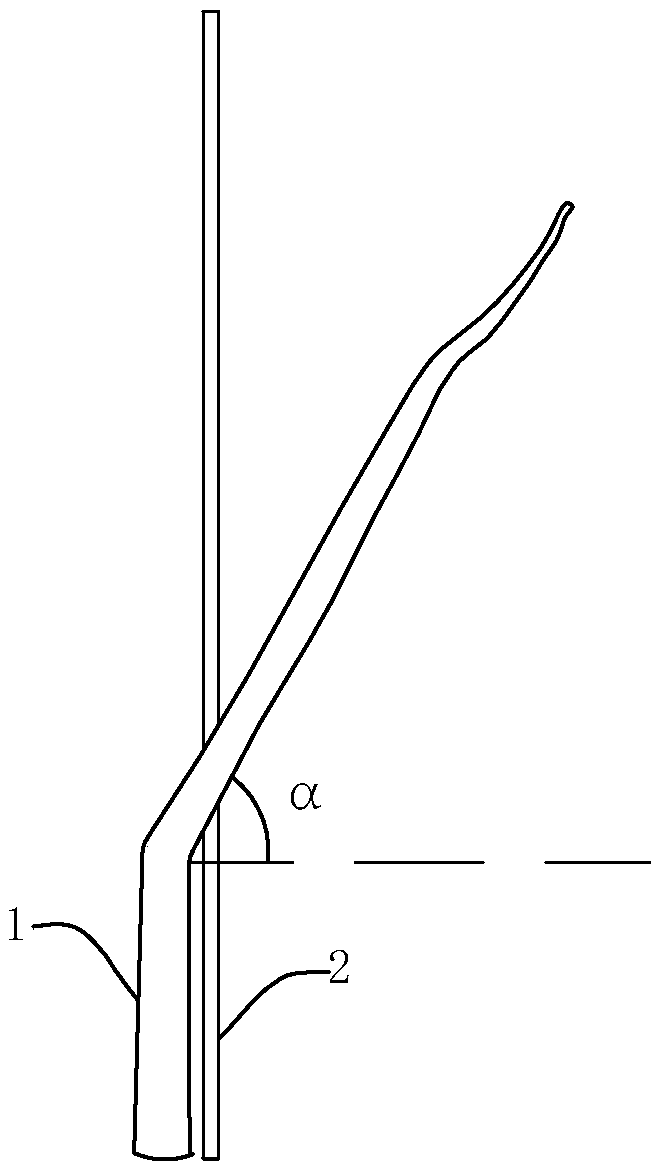

Pruning method of peach trees

InactiveCN105494019AImprove ventilationAvoid hanging ashCultivating equipmentsHorticulture methodsSocial benefitsFrost

The invention belongs to the technical field of cultivation of peach trees and particularly relates to a pruning method of the peach trees. The pruning method comprises the following steps: (1) from February to April of the present year or after first frost of the last year, carrying out field planting on peach tree seedlings, wherein the pruning height of each peach tree seedling is 35cm-70cm, keeping leaf buds of a pruned part and enabling the leaf buds to germinate into branches; (2) inserting an auxiliary rod besides each planted peach tree seedling so that a trunk of each peach tree seedling vertically grows to 2m-2.5m, and keeping current-year braches adjacent to the trunk; (3) from August to September of the present year or before germination of the next year, pulling the trunks at the part, which is 35cm-70cm far way from the ground, from two sides in turns to be opened, and reshaping the adjacent peach trees according to the shape of falling leftwards and inclining rightwards so that an included angle between the trunk of each peach tree and the ground is 50-60 degrees. The pruning method of the peach trees is applicable to mechanical operation so that manpower is saved; the investment payoff period is shortened, and the aims of early fruiting, high yield, stable yield, labor saving and high efficiency are realized; and large-scale development of industries is facilitated, and economic benefits and social benefits are remarkable.

Owner:孙好欣

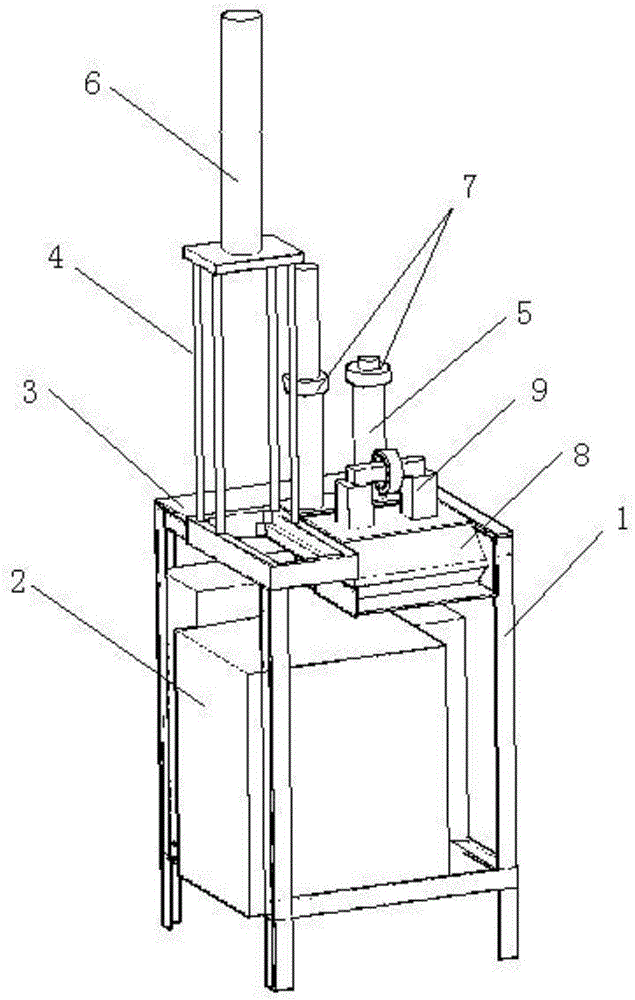

Oil sealing press machine

InactiveCN105014352ASimple structureStable and reliable oil seal pressing effectMetal working apparatusLoad bearingPulp and paper industry

The present invention provides an oil sealing press machine which comprises a frame. The lower part of the frame is a load-bearing unit. The upper part of the frame is a working platform which comprises a cylinder bracket and an auxiliary jig storage rack. The cylinder bracket is equipped with a cylinder, and the lower part of the cylinder is connected to a guide rod. The other end of the guide rod is provided with a clamping port. An auxiliary jig is movably placed on the auxiliary jig storage rack. The working platform just under the cylinder is provided with a through hole. The invention provides the oil sealing press machine which has the advantages of simple structure and stable press effect and is suitable for the mechanized operation of oil sealing pressing.

Owner:苏州金牛精密机械有限公司

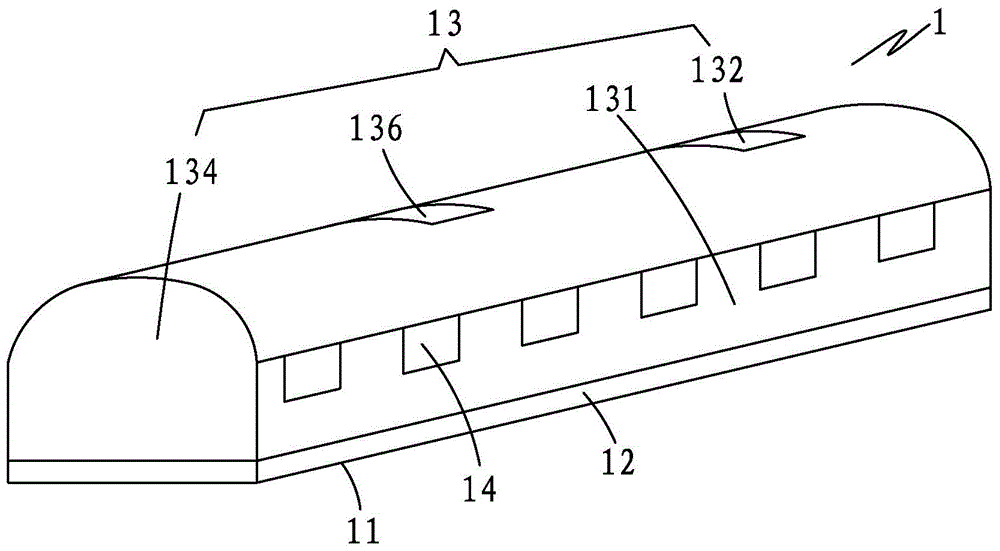

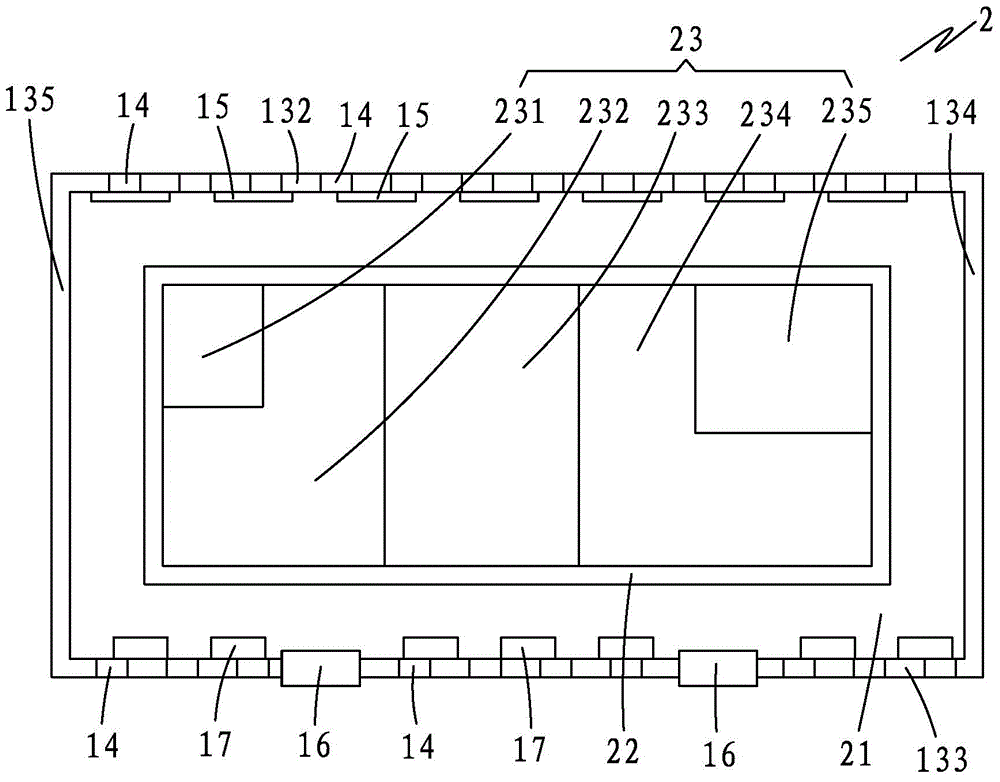

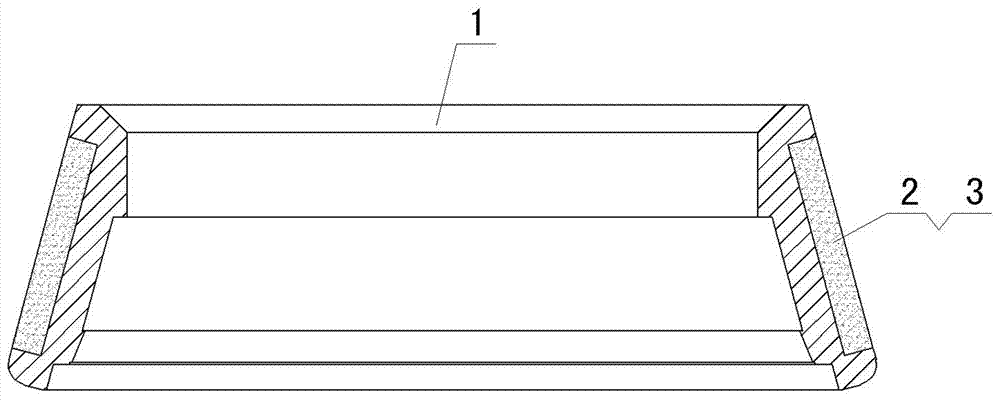

Microbial fermentation bed sow large-column breeding pigsty structure

The invention provides a microbial fermentation bed sow large-column breeding pigsty structure which comprises a pigsty body, pigsty internal configurations and a control cabinet. The pigsty body comprises a rectangular land parcel with the area of 2000-3000 square meters, an enclosure with the height of 0.8-1.2 mm and a steel frame greenhouse, and the height from the highest point on the inner side of a roof of the steel frame greenhouse to the rectangular land parcel is larger than or equal to 7.8 m; the pigsty internal configurations are arranged in the pigsty body and comprise a sidewalk arranged along the long edge side of a pigsty with a gate and an animal yard arranged on the inner periphery of the sidewalk; a fermentation bed padding pit with the depth of 60-80 cm is arranged in the animal yard, and a fermentation bed in the fermentation bed padding pit is divided into five columns; the control cabinet is controlled, so that the temperature in the pigsty body ranges from 29 DEG C to 31 DEG C, and the humidity in the pigsty body ranges from 60% to 80%. The microbial fermentation bed sow large-column breeding pigsty structure is low in construction cost, suitable for mechanical operation, good in ventilation and cooling effects in summer, capable of avoiding heat stress and beneficial to sow farrowing.

Owner:福建省农业科学院农业生物资源研究所

Ecological gabion

InactiveCN105275003AExtended service lifeReduce maintenance workloadExcavationsWeather resistanceBrick

The invention belongs to the field of building materials, and particularly relates to an ecological gabion. The ecological gabion is of a cuboid structure and comprises a tank cover and a tank hinged to the tank cover. The tank is filled with cobbles, small boulders, waste concrete blocks or bricks. The tank is composed of a tank bottom and lateral walls on the periphery. The interior of the tank is divided to be of a multi-layer structure through partition nets horizontally arranged. Multiple vertical partition pieces are arranged between the adjacent partition nets, between the partition nets and the tank bottom as well as between the partition nets and the tank cover at equal intervals; the vertical partition pieces between the adjacent layers are staggered. The ecological gabion is long in service life, high in intensity, high in weather resistance and corrosion resistance, small in maintenance workload, high in integrity, good in stability, good in flexibility, excellent in water permeability, good in mechanical property, high in resistance, resistant to abrasion and environmentally friendly, and has the visual aesthetic effect. The ecological gabion is easy and convenient to construct and can be obtained only by putting stone into the gabion and sealing an opening without special technologies. The weather interference is small, and the ecological gabion is suitable for mechanical operation.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A kind of manufacturing method of composite material grinding roller

ActiveCN104741173BAvoid displacementPromote orderly arrangementGrain treatmentsWave shapeMetal substrate

The invention relates to a composite material grinding roller and a manufacturing method thereof. The composite material grinding roller comprises a metal roller body and a plurality of wave-shaped composite bodies, wherein the wave-shaped composite bodies are embedded into a working plane of the metal roller body at equal intervals, are integrated with the metal roller body and are wave-shaped ceramic reinforcements or wave-shaped structural bodies composited from wave-shaped ceramic reinforcements and a metal substrate; the wave-shaped ceramic reinforcements are prepared by curing ceramic particles. The manufacturing method of the composite material grinding roller comprises the following steps: firstly designing and manufacturing the wave-shaped composite bodies of required sizes; then carrying out casting forming; and finally, cooling and processing, so as to obtain the composite material grinding roller. By virtue of design of the wave-shaped ceramic reinforcements, the composite material grinding roller has the structural characteristics that the ceramic reinforcements are easily and orderly arrayed in a mold cavity and are applicable to mechanical operation; the displacement and the malposition of each individual ceramic reinforcement in a casting process are effectively avoided; the whole displacement of the ceramic reinforcements in a working condition use process is avoided, and particularly, the composite material grinding roller is a secondarily poured large-sized composite material grinding roller.

Owner:GUANGDONG INST OF NEW MATERIALS

Fertilizer special for urea-ammonium nitrate liquid spray and drop irrigation crops and preparation method thereof

InactiveCN105777334AImprove compatibilitySuitable for mechanized operationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCelluloseChelated zinc

The invention discloses a fertilizer special for urea-ammonium nitrate liquid spray and drop irrigation crops and belongs to the technical field of fertilizers special for liquid spray and drop irrigation crops.The fertilizer is prepared from a urea-ammonium nitrate solution, monoammonium phosphate, potassium carbonate, citric acid chelated copper, EDTA chelated zinc, borax, potassium fulvic, sodium carboxymethyl cellulose and water.Compared with an existing technology, the fertilizer has the advantage of low cost, comprehensive nutrients and high fertilizer utilization rate.

Owner:STANLEY AGRI GRP CO LTD

Method for using female sterility gene fst in hybrid rice breeding

InactiveCN101658129BAvoid Mechanical MixingAccelerate the application processPlant peptidesGenetic engineeringAgricultural scienceHybrid seed

The invention relates to a method for using female sterility gene FST in hybrid rice breeding, and belongs to the field of breeding in the field of agricultural biotechnology. The technical scheme of the present invention is to reproduce the male sterile line according to the three-line or two-line method; the reproduction of the rice female sterile line can be completed by the perennial root asexual reproduction method, or the conditionally expressed dual-purpose transgenic female sterile line can be cultivated, By artificially regulating the expression of the FST gene, the female fertility is restored and self-reproduction is completed; when producing seeds, the male sterile line and the female sterile line are planted in the same field, the pollen recipient is the male sterile line, and the pollen donor is the female CMS, the female CMS pollinates the male CMS, and the seeds are harvested as hybrids. The invention utilizes male sterility (MS) and female sterility (FS) simultaneously to construct a "MS+FS" seed production mode, which is suitable for mechanized operation, prevents mechanical mixing of restorer lines, and can accelerate the popularization and application process of hybrid rice.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Mild type chemical conditioner applicable to saline-alkali soil and preparation and application methods thereof

InactiveCN109824429ASpeed up the processRapid Salt and Alkaline TreatmentFertiliser formsFertilizer mixturesAlkali soilPolyethylene glycol

Disclosed are a mild type chemical conditioner applicable to saline-alkali soil and preparation and application methods thereof. The mild type chemical conditioner applicable to the saline-alkali soilis composed of an internal layer and an envelope layer, wherein the internal layer is composed of, by weight part, 40-50 parts of phosphogypsum, 15-20 parts of aluminum sulfate, 20-25 parts of humicacid, 10-15 parts of corncob powder and 5-8 parts of polyethylene glycol; the envelope layer is composed of water-soluble high-polymer polyacrylamide 0.08-0.12 time by weight as much as the mixed system of the internal layer. The mild type chemical conditioner applicable to the saline-alkali soil solves a series of practical problems of slow saline-alkali soil desalination process, significant alkalization trend during desalination, slow effects and long cycle of the prior art and the like.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Rod and wire rod labeling method

InactiveCN109677727ASuitable for mechanized operationIncrease productivityAffixing tagsLabelling elongated objectsManipulatorLabelling

The invention discloses a rod and wire rod labelling method which comprises the following steps: transversely placing a rod or a wire rod on a roller, conveying the rod or wire rod through the roller,adopting an optoelectronic switch to position the position of the rod or wire rod, adopting the positioned rod or wire rod to read the position coordinates of the end face center of the rod or a wirerod strapping tape through machine vision, sending the position coordinates to a manipulator, wherein the manipulator can be a joint manipulator, a spider hand or a guide rail structure, adopting themanipulator to grab a printed label and paste the label at a labeling position, and welding and fixing the label. With adoption of the rod and wire rod labeling method, the labelling position can beprecisely found, high-temperature environment operation is applicable, the label is fixed on the rod or wire rod through welding and unlikely to fall off, can resist high temperature, can realize automatic production, improves the automation efficiency of an enterprise and reduces manual work.

Owner:武汉鹏源激光技术有限公司

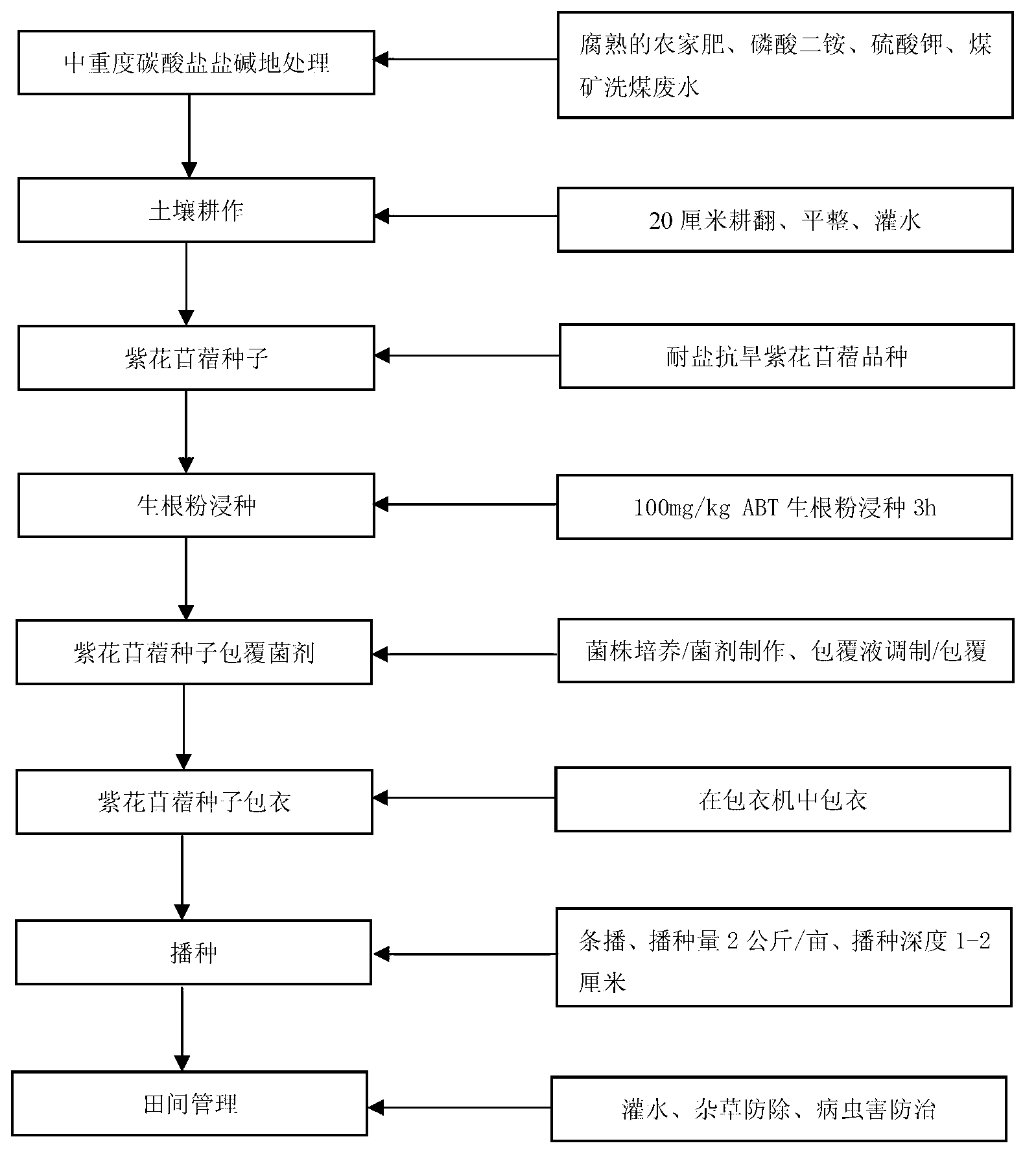

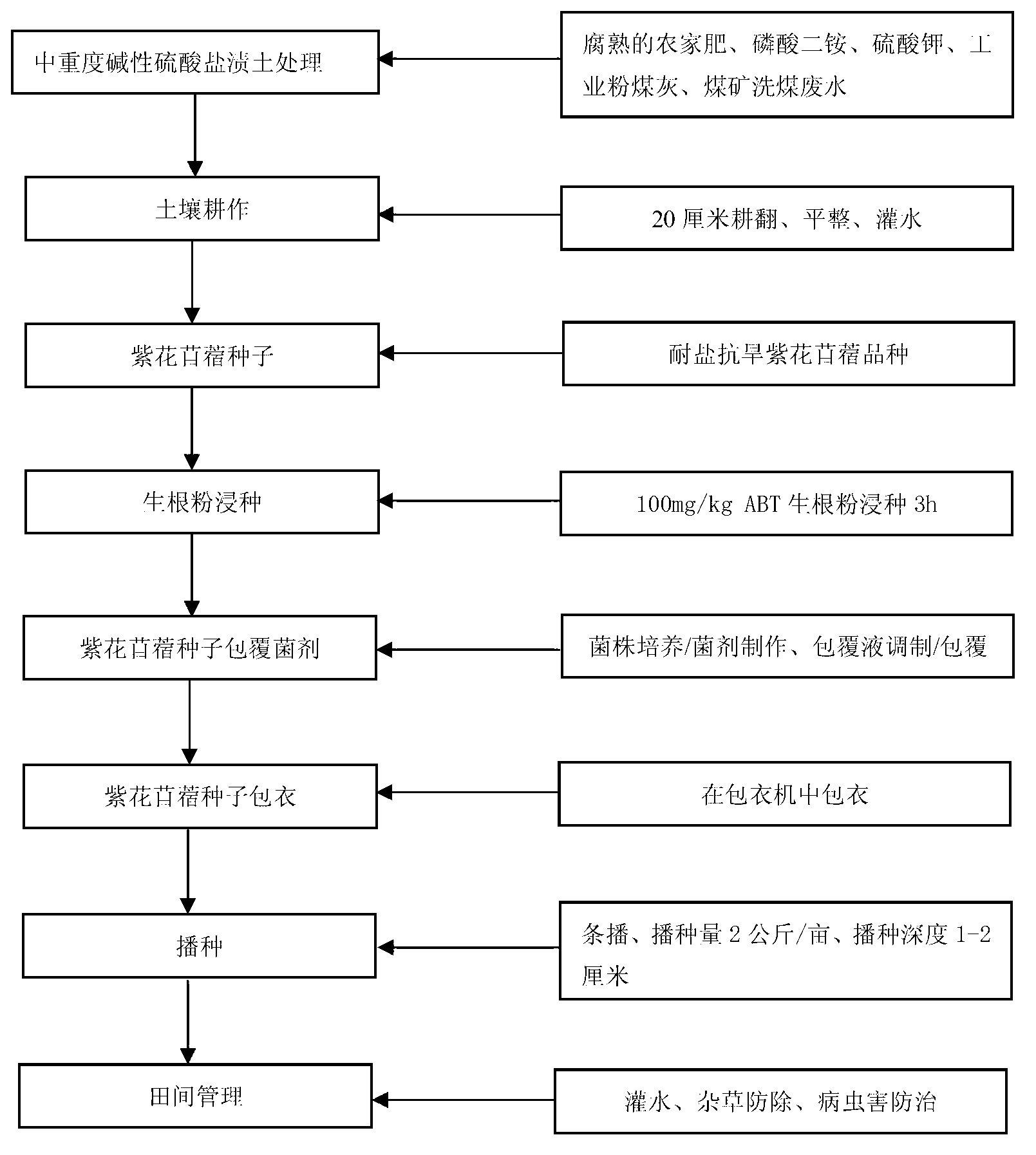

Method for planting alfalfa in moderately severe carbonate saline-alkali soil on large scale

InactiveCN102845204BRapid emergenceImprove seedling rateSeed coating/dressingHorticultureAlkali soilDiammonium phosphate

Owner:DALIAN NATIONALITIES UNIVERSITY

Plastic film mulching technique allowing peanut seedlings to automatically growing out of film

InactiveCN105684702ASave human effortShorten the timeClimate change adaptationPlant cultivationPlastic mulchEngineering

The invention relates to a plastic film mulching technique allowing peanut seedlings to automatically growing out of a film. The technique comprises the steps of 1, land selection, fertilization and furrowing or ridging; 2, making shallow trenches on the surfaces of furrows or ridges; 3, sowing at the depth of 1+ / -0.5 cm; 4, marking the positions of seeds, and conducting plastic film mulching; 5, covering a plastic film with a layer of soil along marking lines; 6, needing no artificial film rupture or movement of soil on the film.

Owner:LINYI UNIVERSITY

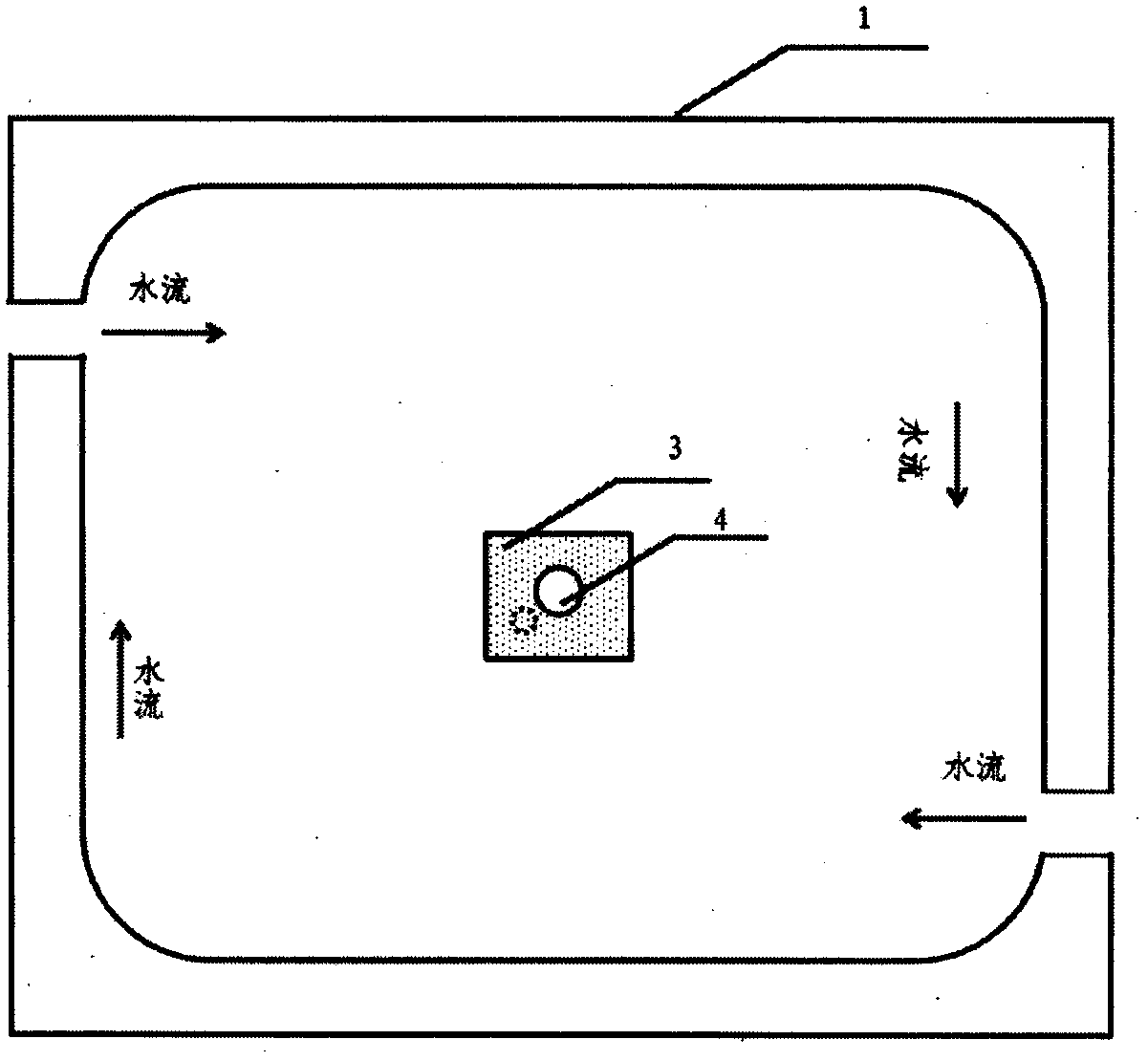

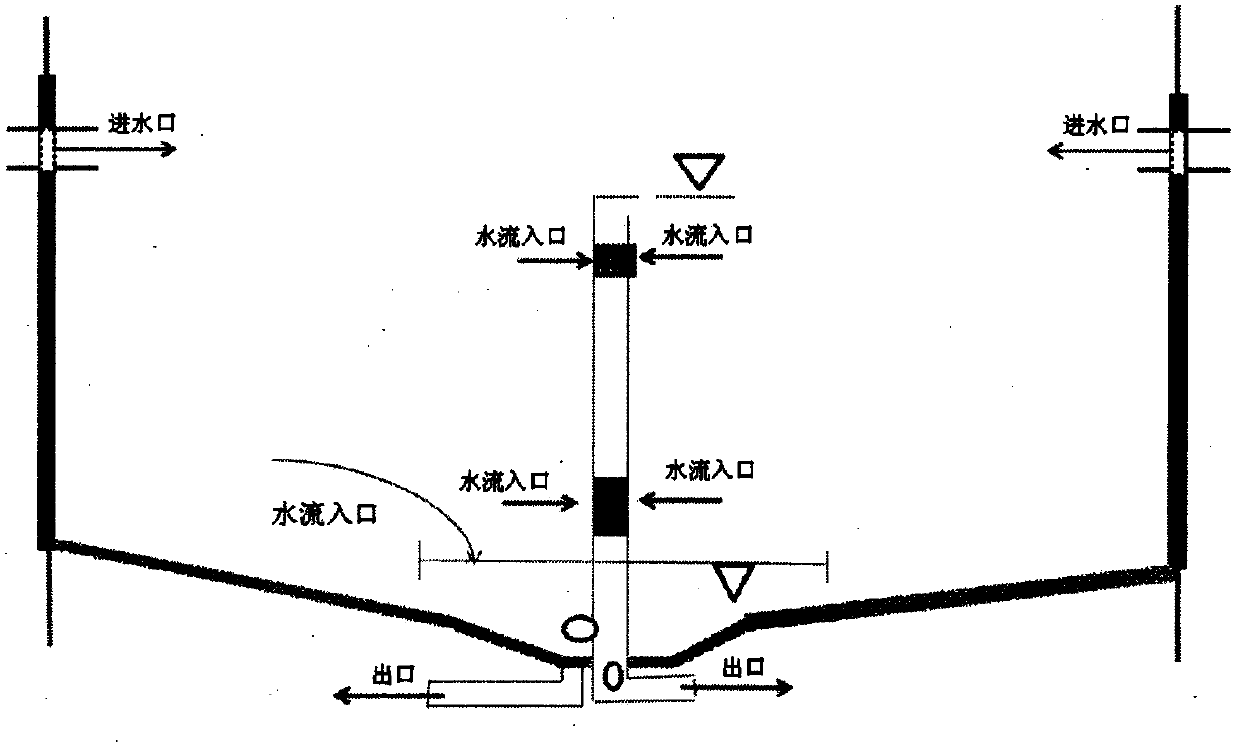

Novel pond internal circulating water breeding system

PendingCN109964868AEasy to cleanGuaranteed cleanlinessPisciculture and aquariaSuspended particlesFeces

The invention discloses a novel pond internal circulating water breeding system. The novel pond internal circulating water breeding system is composed of a breeding pond, a shunting blown-down system,water inflow pipes and a water drain pipe. The breeding pond is a square fillet gradient cement pond. The shunting blow-down system comprises a dirt collecting funnel, a station pipe, a precipitatedparticle channel pipe, a suspended particle channel pipe and a precipitation and filtration pond with a first filtering brush and a second filtering brush. The cement pond water inflow pipes are reversely mounted at opposite corners or on the same sides along the upper edge of the pond. The dirt collecting funnel is arranged in the middle of the bottom of the pond and connected to the precipitation and filtration pond through the precipitated particle channel pipe and connected to the pond through the water drain pipe. Water drain holes are formed in the portions, at the upper end of the dirtcollecting funnel and the upper end and the lower end of a water line, of the station pipe, and the station pipe penetrates through the middle of the dirt collecting funnel and is connected to the pond through the suspended particle channel pipe and the exhaust pipe. The novel pond internal circulating water breeding system is suitable for fish high-density intensive breeding, fish feces and residual feed can be effectively collected, the collecting rate reaches 70% or above, suspended particles in water and oil dirt and foams on the surface can be discharged in time, environmental friendliness is achieved, and the breeding cost is reduced by 10%-30%.

Owner:SHEYANG KANGYU AQUATIC PROD TECH +1

Method of Grafting and Raising Seedlings of Thin-skinned Melon in Spring

Owner:ANQING JINDADI ECOLOGICAL AGRI DEVCO

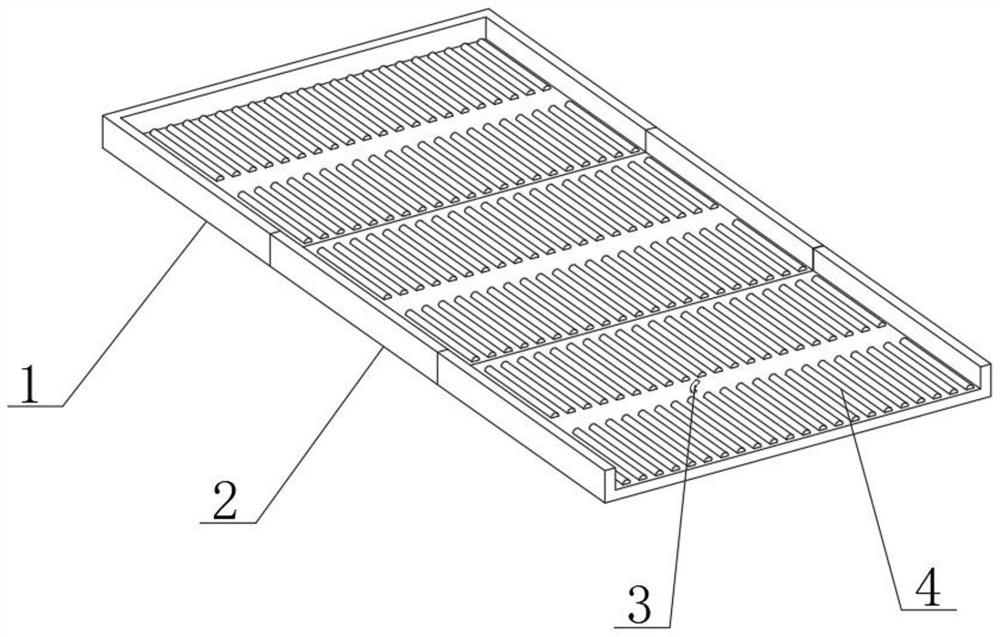

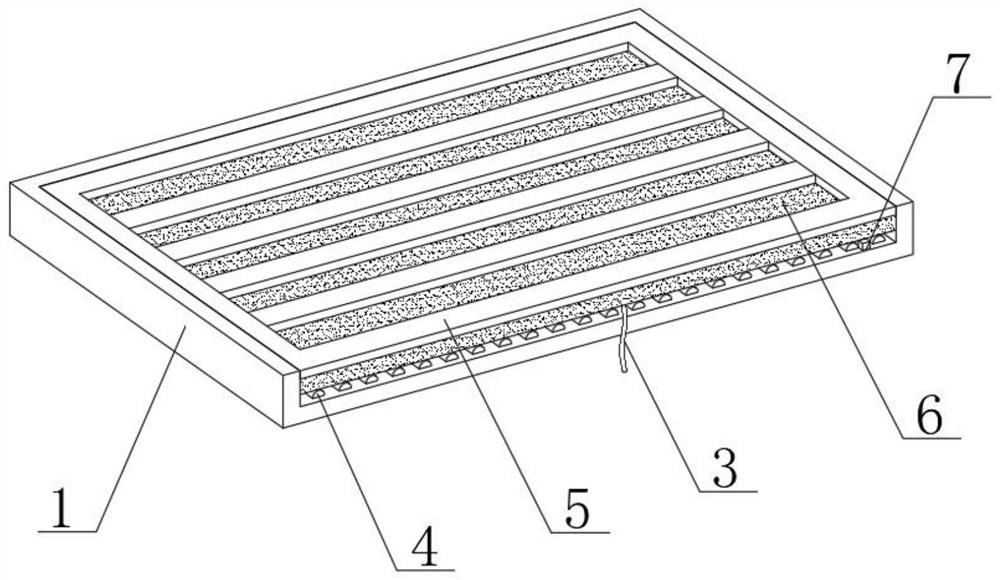

Novel leafy vegetable planting device and planting method

InactiveCN111955336AEasy to operateSuitable for mechanized operationAgriculture gas emission reductionCultivating equipmentsLeafy vegetablesAgricultural engineering

The invention discloses a novel leafy vegetable planting device and planting method. The planting device comprises an end frame and a plurality of connecting frames, wherein the end frame is connectedwith the ends of the connecting frames in an attached mode, the width and the height of the end frame and the connecting frames are equal, a matrix layer is placed on the inner sides of the end frameand the connecting frames, a planting cover plate is placed on the surface of the matrix layer, the top end face of the planting cover plate and the top end face of the end frame are located on the same plane, a plurality of supporting columns are evenly arranged on the bottom faces of the inner sides of the end frame and the connecting frames, each supporting column is of a semi-cylinder structure, and the top end faces of the supporting columns are connected with the bottom end face of the matrix layer in an attached mode. The operation is simple and convenient, and higher professional requirements are not needed; the device is suitable for mechanical operation; water supply is convenient and fast; the repeated utilization rate is high; and the culture layers are made of EPO material, which is environmentally friendly and harmless, and can be continuously connected.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

Extreme group turnover fixture

InactiveCN104129548BSuitable for manual operationSuitable for mechanized operationRigid containersSlide plateEngineering

The invention provides a pole group turnover clamp, comprising a bottom plate and a sliding plate slidably matched with the bottom plate, a spring is arranged between the bottom plate and the sliding plate, and the spring slides against the bottom plate and the bottom plate in the sliding direction of the sliding plate relative to the bottom plate The plate has an acting force, a plurality of splints are arranged on the bottom plate and the sliding plate, the splints are arranged in a row in the sliding direction of the sliding plate relative to the bottom plate, and the splints on the bottom plate and the sliding plate are distributed at intervals The bottom plate is provided with two baffle plates arranged in parallel, the baffle plates extend along the sliding direction of the sliding plate relative to the bottom plate, and the clamping plate is located between the two baffle plates. After using the pole group turnover fixture, the lead-acid battery pole group is suitable for both manual operation and mechanized operation during turnover, and can also be used for forklift turnover, conveyor chain turnover and other modes.

Owner:长兴大宇科机电有限公司

A kind of industrialized seedling raising method of green onion

ActiveCN105557492BImprove qualityIncrease resistanceBulb cultivationGrowth substratesPlant diseaseRidge

The invention discloses an industrialized seedling culture method for Chinese onions. A seedling shed is set up according to a conventional method, a seedbed is arranged in the seedling shed, soil in the seedbed is leveled, and ridges are formed. The method specifically includes the following steps of firstly, laying gauze on the seedbed; secondly, filling a nursery seedling plate with a matrix; thirdly, pre-processing seeds before sowing; fourthly, sowing the seeds; fifthly, conducting film mulching; sixthly, managing the seedbed; seventhly, conducting disease control at the seedling stage; eighthly, improving the growth of roots and seedlings. When Chinese onion seedling culture is conducted through the seedling culture technology, the number of seeds which are used is small, seedling emergence is quick, seedlings are robust and resist diseases, root systems are developed, the environment can be artificially controlled for industrialized seedling culture, mechanical transplantation is facilitated, seedling recovery is quick after transplantation, seedling lands are saved, the seedling culture cost is greatly saved, and good development prospects are achieved.

Owner:山东沃华农业科技股份有限公司

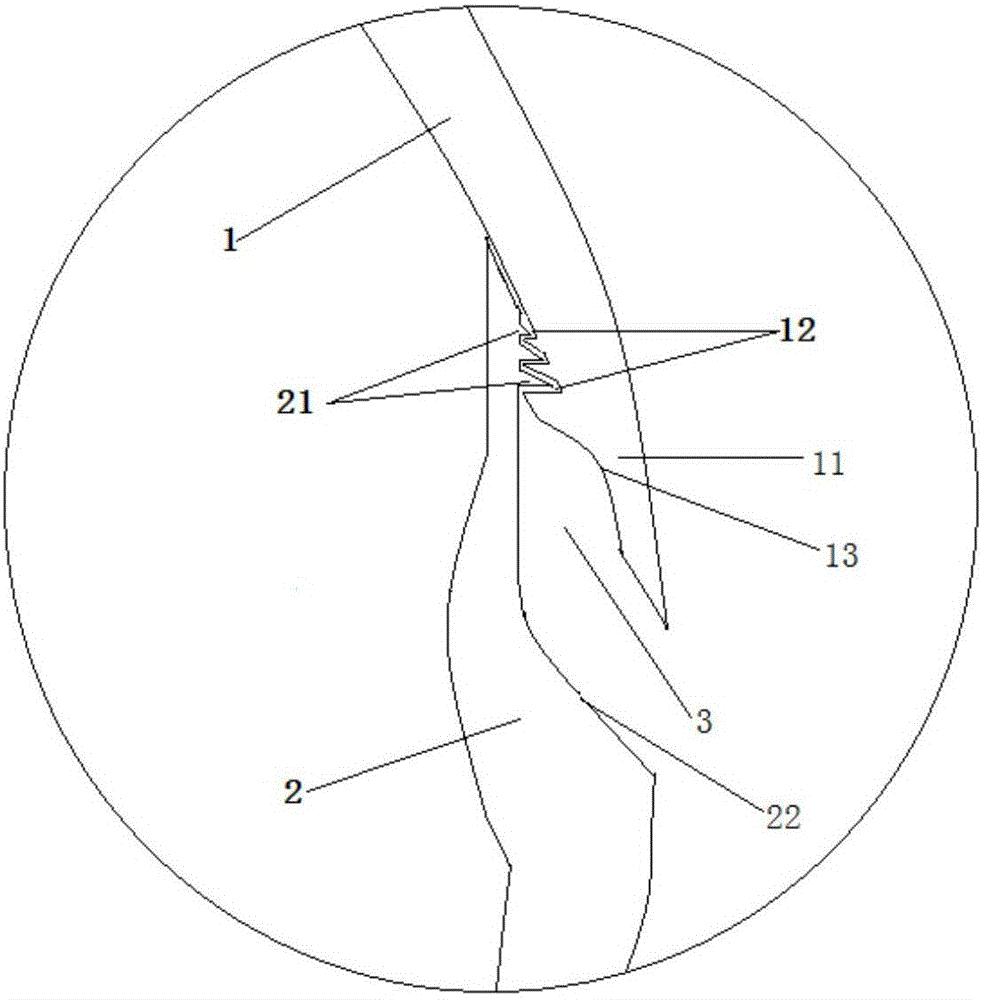

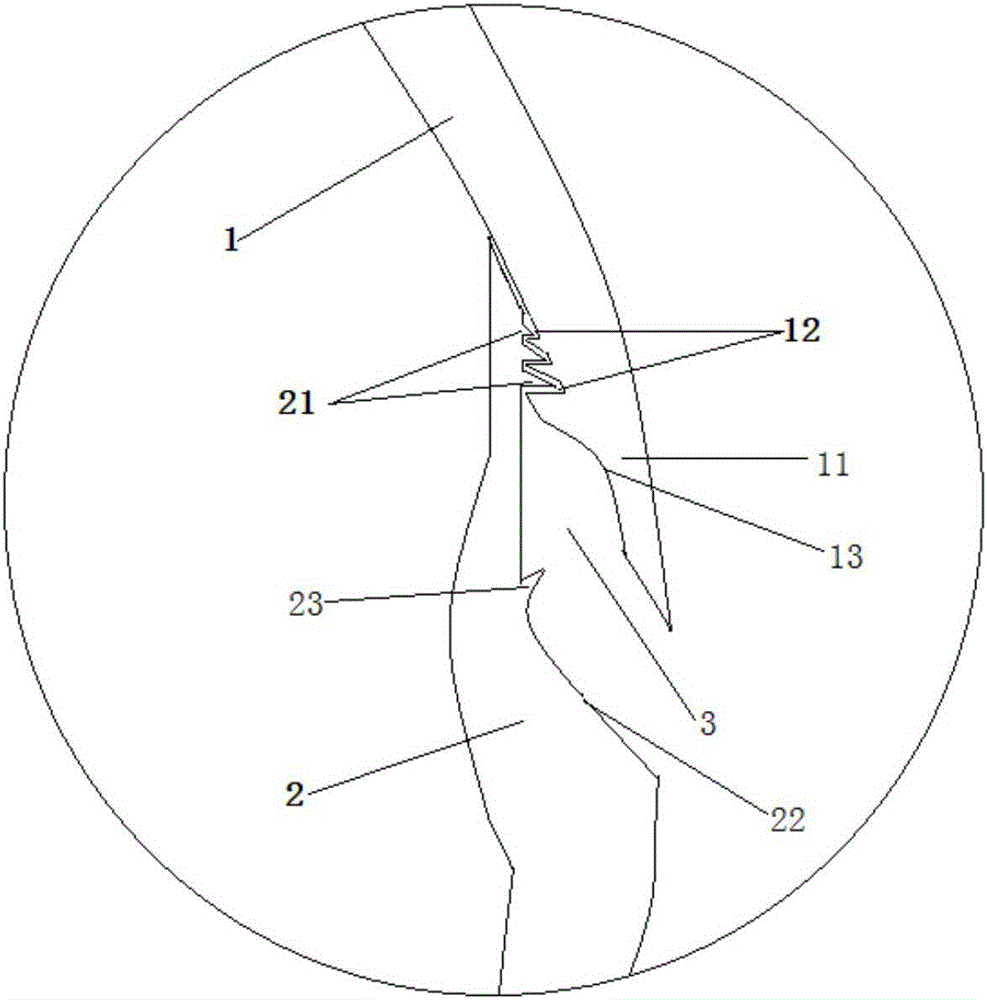

Wax-sealed spherical shell with zigzag buckling structure

PendingCN105997504AHigh buckleImprove sealingPharmaceutical containersMedical packagingNeck partsStructural engineering

The invention belongs to the technical field of drug and food packaging and specifically relates to a wax-sealed spherical shell with a zigzag buckling structure. The wav-sealed spherical shell provided b the invention is characterized in that a head part of a bottom shell buckling tongue is a zigzag buckling round edge; an annular body inclined gap is cut on a neck part of the buckling tongue; a facial shell comprises a tongue-shaped round edge; an annular body groove is formed in the inner side of the tongue-shaped round edge; the facial shell body and the tongue-shaped round edge of the facial shell form a zigzag groove which is matched with the zigzag buckling round edge of the head part of the bottom shell buckling tongue; and after buckling of the facial shell and the bottom shell, an open inclined cut-in whole-body annular groove is formed in the buckling part. In comparison with the prior art and existing products, the wax-sealed spherical shell has the advantages that the buckling degree is high; the wax-sealed layer does not suffer from brittle fractures easily; and the sealing degree is high.

Owner:TAISHAN XINHUA OFFICIAL PHYSIC PACKAGE

Method for planting alfalfa in moderately severe alkaline sulfuric acid saline soil on large scale

InactiveCN102845203BRapid emergenceImprove seedling rateSeed coating/dressingHorticultureCoalChemistry

The invention discloses a method for planting alfalfa in a moderately severe alkaline sulfuric acid saline soil on a large scale. The method comprises the steps as follows: (1), broadcasting fully rotten a farming manure, diammonium phosphate, potassium sulfate and industrial coal ash on the surface of the moderately severe alkaline sulfuric acid saline soil, and uniformly spraying coal-washing wastewater; (2), ploughing, leveling and irrigating the moderately severe alkaline sulfuric acid saline soil; (3), selecting alfalfa seeds of a salt-tolerant and drought-resistant variety, and soaking the seeds by using ABT rooting powder; (4), covering the soaked alfalfa seeds with bactericides with alfalfa root nodule bacteria; (5), coating the alfalfa seeds covered with the bactericides; (6), sowing the coated alfalfa seeds into the moderately severe alkaline sulfuric acid saline soil; and (7), after seedling emergence, carrying out field management. The method can be used for planting the alfalfa in the moderately severe alkaline sulfuric acid saline soil on a large scale, and has the characteristics of high seedling emergence speed, high seedling percentage, simplicity for operation, suitability for mechanical operation, easiness in manual control and the like.

Owner:DALIAN NATIONALITIES UNIVERSITY

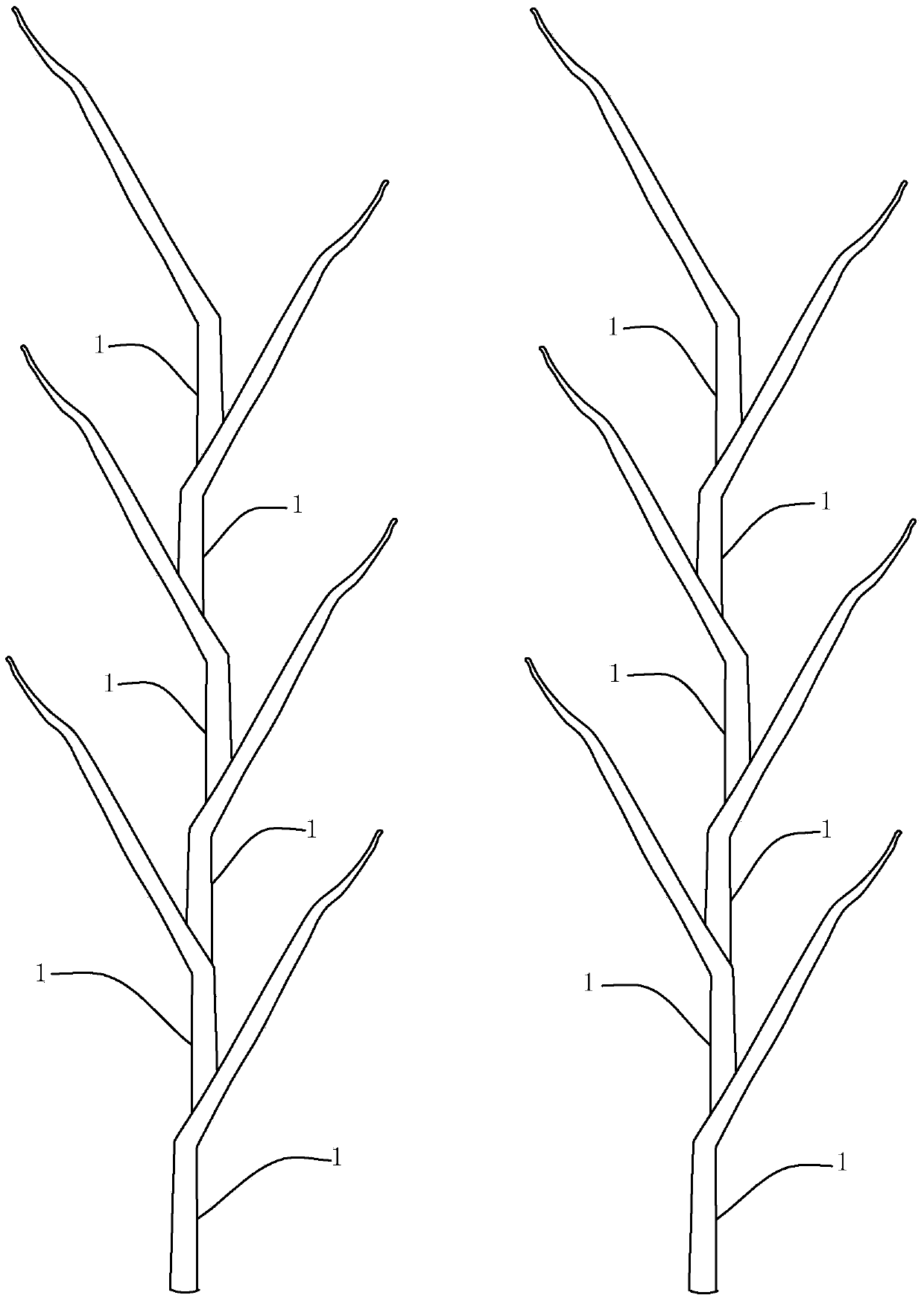

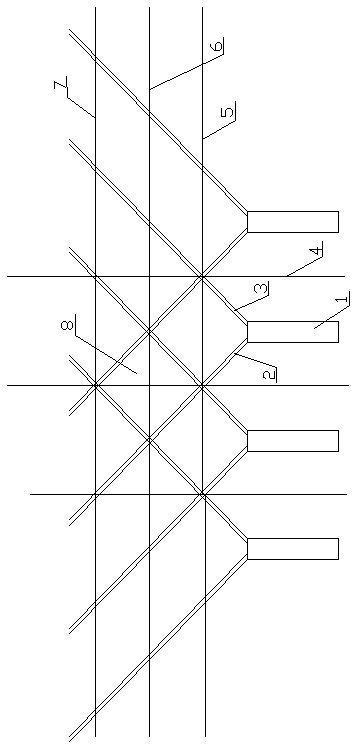

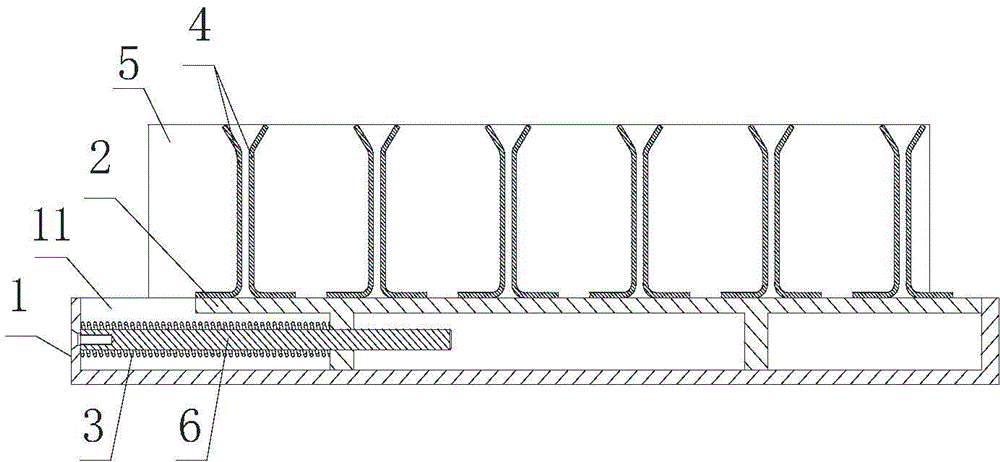

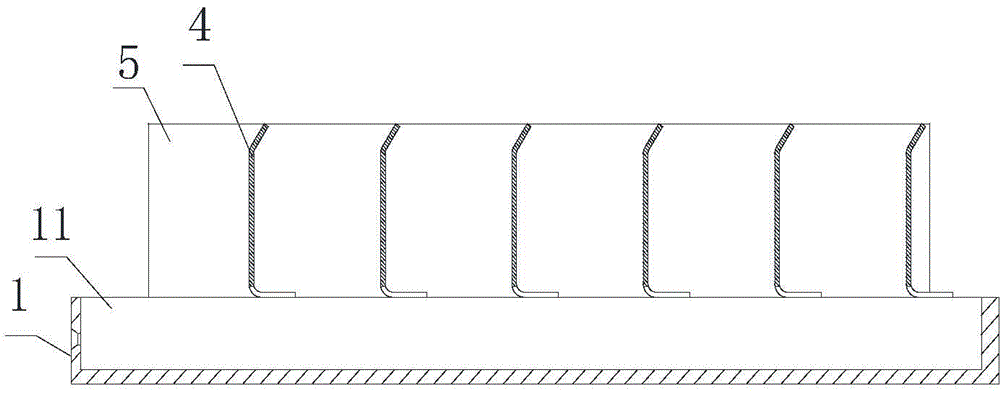

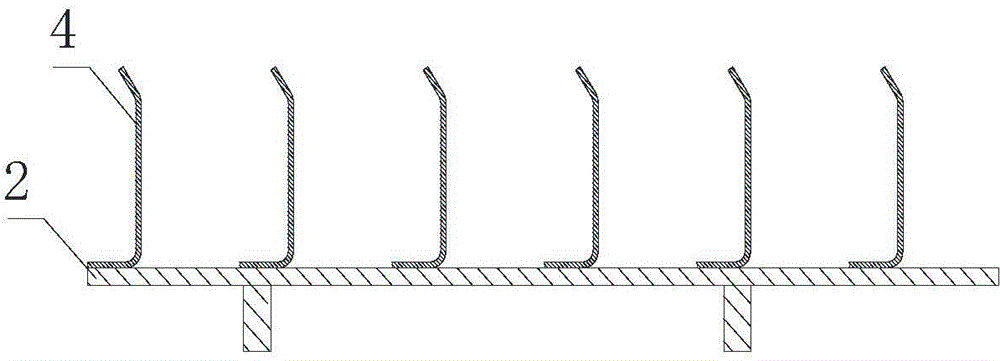

Vertical plane meshing tree shape, vertical plane meshing tree-shape shaping method for pear tree plantation and application of vertical plane meshing tree shape and shaping method

InactiveCN111296109AEasy to manageImprove management abilityCultivating equipmentsHorticulture methodsPear treeEngineering

The invention discloses a vertical plane meshing tree shape, a vertical plane meshing tree-shape shaping method for a pear tree plantation and application of the vertical plane meshing tree shape andshaping method. The vertical plane meshing tree shape includes a pear trunk, wherein a pear trunk comprises a central trunk (1), a first main trunk (2) and a second main trunk (3), the first main trunk (2) is connected with the second main trunk (3) in a lapping mode, and a fruit hanging vertical plane with meshing distribution is formed by the first main trunk (2) and the second main trunk (3). Chemical spraying, fruit picking and pollination of pear trees can be managed mechanically and conveniently, and the management effect of the pear tree plantation is improved.

Owner:SHANDONG INST OF POMOLOGY

Plate group transferring clamp

InactiveCN104129548ASuitable for manual operationSuitable for mechanized operationRigid containersSlide plate

The invention provides a plate group transferring clamp which comprises a bottom plate and a sliding plate in sliding fit with the bottom plate. A spring is arranged between the bottom plate and the sliding plate, and the spring has action force to the bottom plate and the sliding plate in the direction that the sliding plate slides relative to the bottom plate. A plurality of clamping plates are arranged both on the bottom plate and the sliding plate, the clamping plates are distributed in an array in the direction that the sliding plate slides relative to the bottom plate, and the clamping plates on the bottom plate and the clamping plates on the sliding plate are distributed at intervals. The bottom plate is provided with two baffles which are arranged in parallel, the baffles extend in the direction that the sliding plate slides relative to the bottom plate, and the clamping plates are placed between the two baffles. After the plate group transferring clamp is used, lead-acid cell plate groups are suitable for manual operation and also suitable for mechanical operation in the transferring process, and meanwhile the plate group transferring clamp can be applied to the modes of fork forklift transferring, conveying chain transferring and the like.

Owner:长兴大宇科机电有限公司

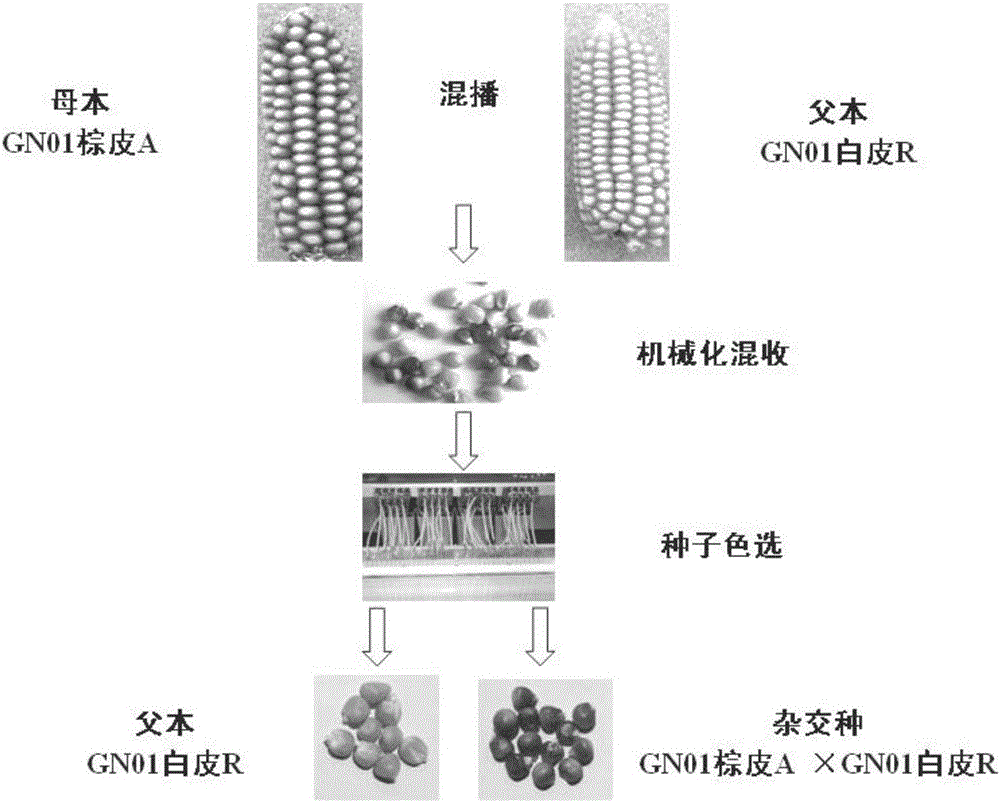

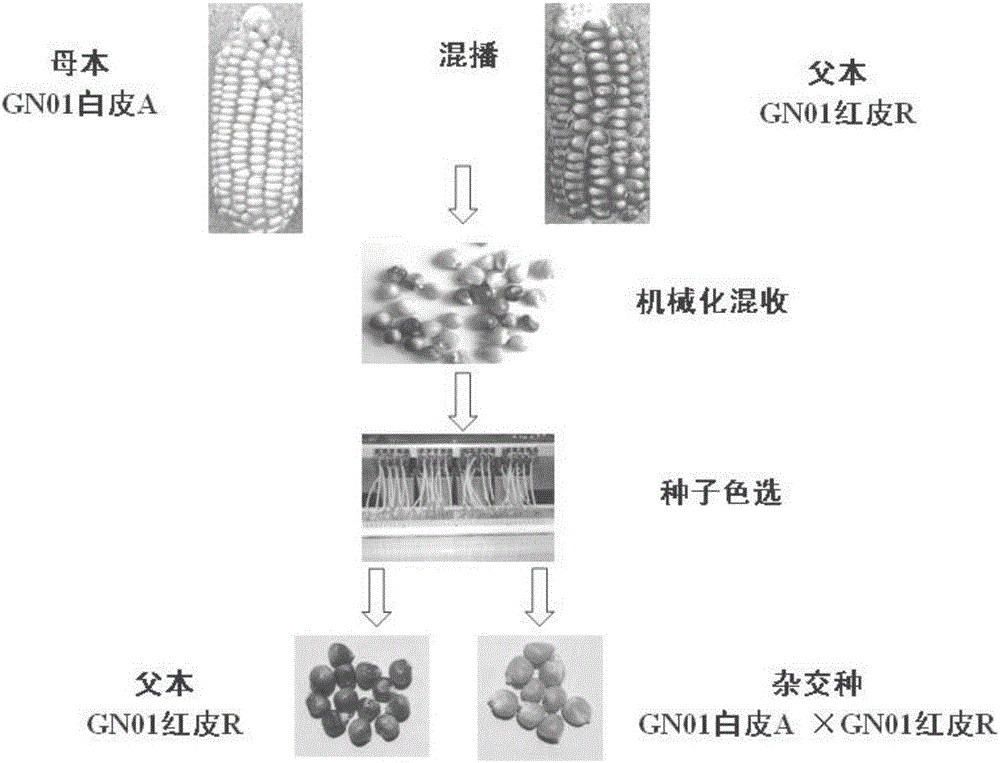

Corn difference peel color CMS three line breeding and application thereof in mixed-planting production

InactiveCN107173216ARealize mechanized productionConvenient self-managementPlant genotype modificationAngiosperms/flowering plantsHybrid seedSeparation technology

The invention discloses difference peel color corn cytoplasmic male sterility three line breeding and a production and utilization method thereof. A special peel color gene is respectively introduced into a corn CMS male sterile line or a restoring line through hybridization, backcross and self-cross ways, the difference of peel color is creased between hybrid parents, sterility mixed-planting production is adopted to be combined with a seed color separation technology, and a corn hybrid seed is produced. The invention has the beneficial effects that with sterility production, an artificial emasculation process can be removed, the production cost is reduced, the hybrid seed purity is improved, and large-scale seed field management and centralized production are facilitated; with mixed-planting production, a corn hybrid seed production mode can be simplified, the seed production mechanical degree is improved, and the production cost is reduced; with seed color section, the hybrid seed purity and the seed quality can be ensured, the safe, high-efficient, intensive and mechanical production of the corn hybrid seed is realized, and the positive significance is played on ensuring the quality safety of the hybrid corn seed, reducing the production cost of the seed, and relieving rural labor shortage.

Owner:GANSU AGRI UNIV

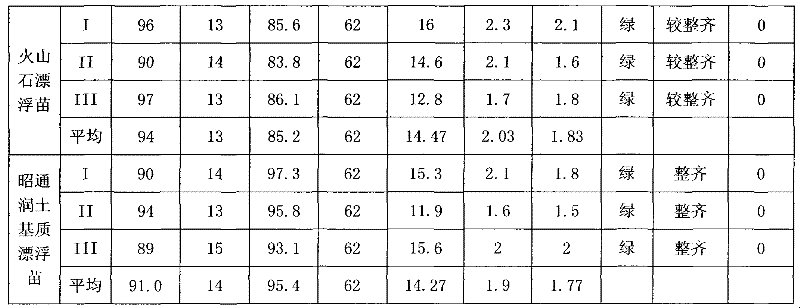

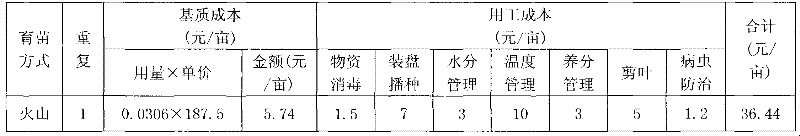

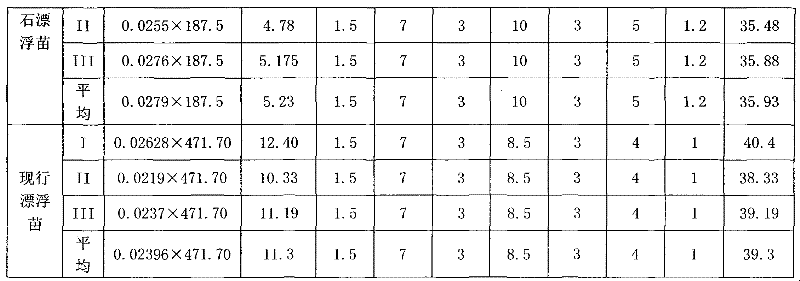

Method for cultivating tobacco seedlings by taking vesuvianite particles as floating seedling matrix

InactiveCN102077780BReduce seedling costReduce manufacturing costCultivating equipmentsSoilless cultivationVesuvianiteBiology

The invention discloses a method for cultivating tobacco seedlings by taking vesuvianite particles as a floating seedling matrix, which belongs to the technical field of tobacco breeding. The method comprises the following steps of: using a vesuvianite particle material as a seedling matrix, wherein particle sizes and mass ratios of the vesuvianite particle material are that the vesuvianite particles with the particle size of 1mm accounts for 40 percent and the vesuvianite particles with the particle size of between 2 and 5mm accounts for 60 percent; dissolving a universal nutrient liquid fertilizer for floating seedling of flue-cured tobacco, and then fully mixing with the vesuvianite particles, wherein each cube of the vesuvianite particles use 2kg of the universal nutrient liquid fertilizer for the floating seedling of the flue-cured tobacco; loading the vesuvianite particles into a disk and sowing, wherein the water content of the vesuvianite particles is appropriate when no sand is leaked from a bottom hole after the vesuvianite particles are loaded into the disk; placing the disk into a floating seedling pond, wherein water in the floating seedling pond is underground water or well water with the pH value of between 6.0 and 7.0; placing the nutrient fertilizer into the pond with the depth of 12cm according to the using amount of 2kg per cube of water on the day before the sowing; placing the nutrient fertilizer into the pond with the depth of 12cm according to the using amount of 1kg per cube of water on the 40th day after the sowing; controlling the seedling temperature to be between 27 and 32 DEG C and the relative humidity to be between 65 and 80 percent; and operating and managing other floating seedling steps according to the conventional method. The method has the advantages of low seedling and production cost, simplicity and convenience for operation, safety and no pollution and high and thick stems of the tobacco seedlings.

Owner:云南省烟草公司保山市公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com