Multi-channel high-density ultra-narrow stretchable microelectrode and preparation method and application thereof

A high-density, micro-electrode technology, applied in applications, electrodes, diagnostic recording/measurement, etc., can solve problems such as high cost, complicated packaging process, and complicated operation, and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

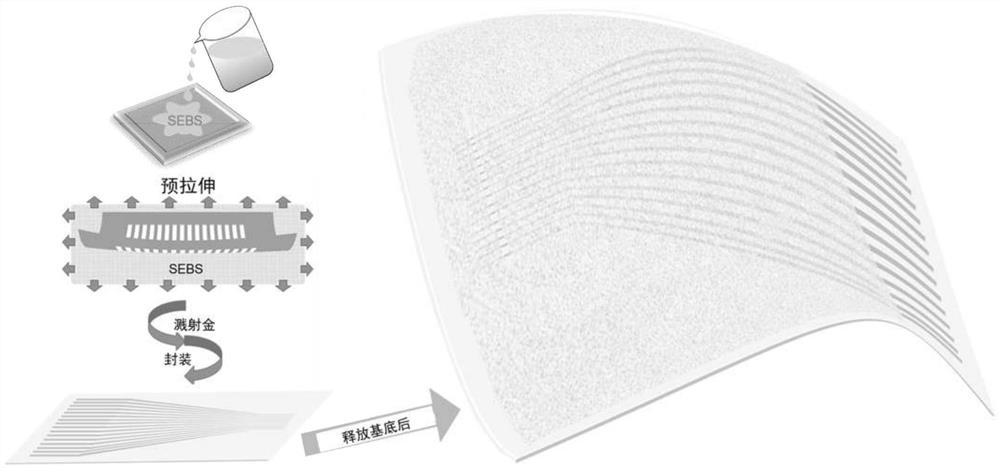

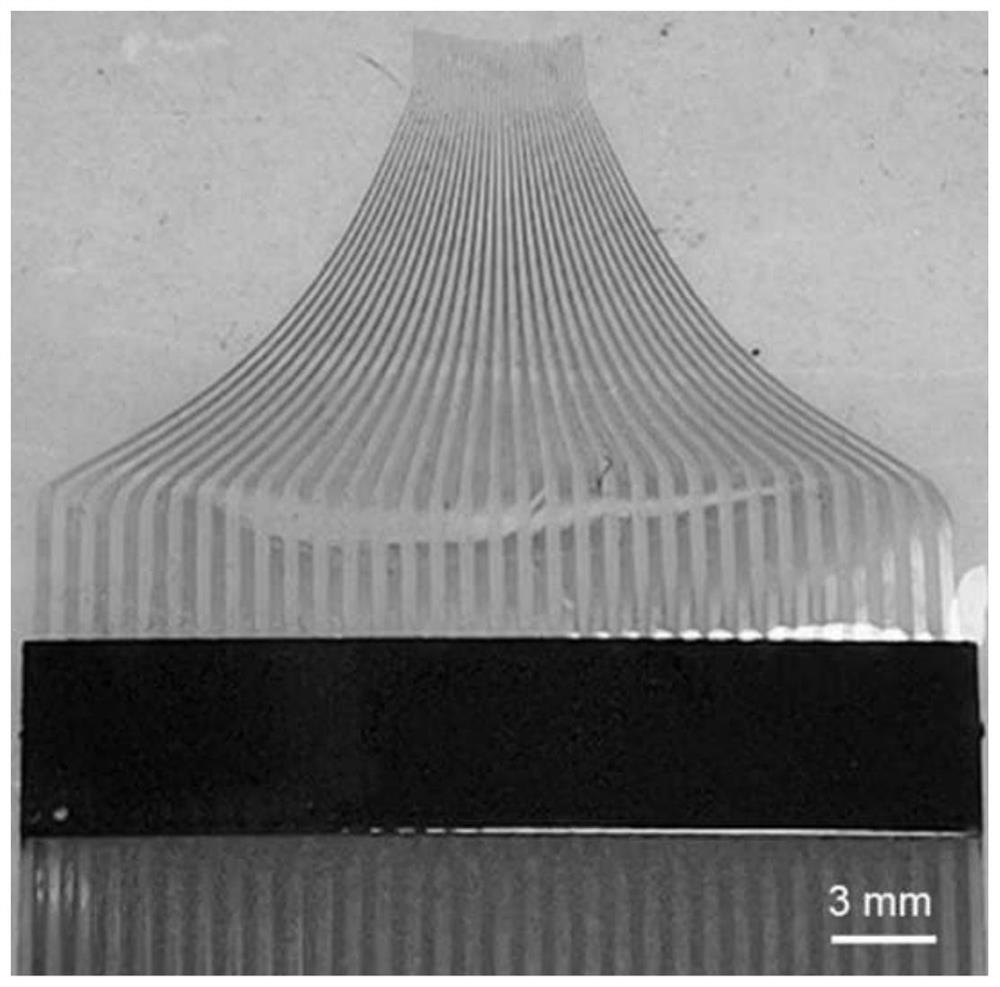

[0039] In this example, a 32-channel high-density ultra-narrow stretchable microelectrode is prepared. The preparation method is as follows: figure 1 shown, including the following steps:

[0040] (1) Preparation of flexible substrate: Pour 15% by mass of SEBS toluene solution into a square polytetrafluoroethylene (PTFE) mold, air-dry to obtain a SEBS film with a thickness of about 300 microns, and the SEBS film faces the inner bottom of the mold One side of the mold has the inverted mold shape of the mold, which is a fog-like and incompletely flat state, which is recorded as the back side, and the other side is the flat shape after natural air drying, which has strong viscous and self-adhesive properties, and is recorded as the front side;

[0041] (2) Pre-stretching and fixing of the flexible substrate: the back of the flexible substrate is pasted and fixed with tape, which is recorded as the fixed area; the flexible substrate is pre-stretched, and the fixed area is not defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com