Water-soluble cutting oil applied to cutting work and guide rail lubrication

A cutting and water-soluble technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of accelerating bacterial growth, contaminating the diluent, increasing the difficulty and cost of cleaning, reducing oil cost and achieving good anti-wear properties. Effect

Inactive Publication Date: 2014-11-05

KAIFENG AOKEBAO SPEICAL OIL AGENT CO LTD

View PDF5 Cites 46 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology improves upon existing methods by adding an emulsion containing certain chemicals that improve their properties such as wearability or ability to stick on materials like rails without causing damage. Additionally, this solution allows for better control over how much fluid enters into machinery parts while still maintaining high levels of cleanliness.

Problems solved by technology

This patented technical problem addressed in this patent relates to improving traditional water solubility cutting oil used by machines tools that use it without causing harm or damage from leaks caused by other materials like guiding oil onto the guide rails inside the machine's main body.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

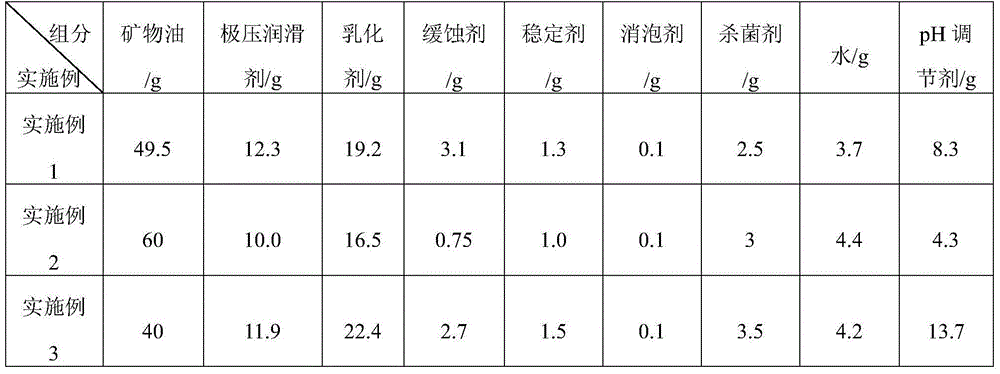

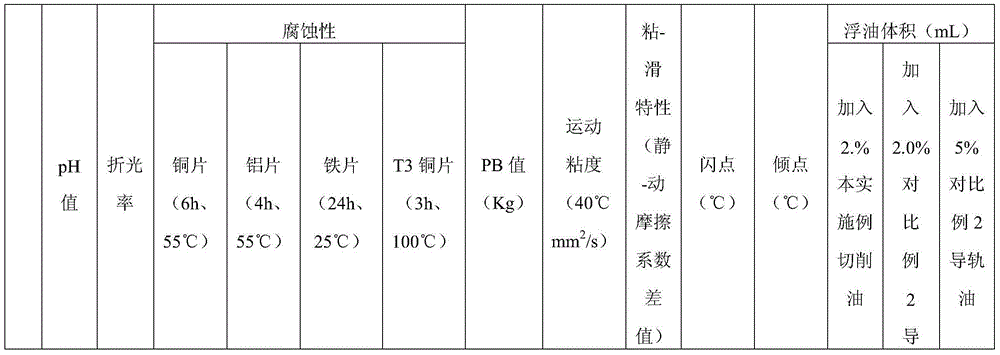

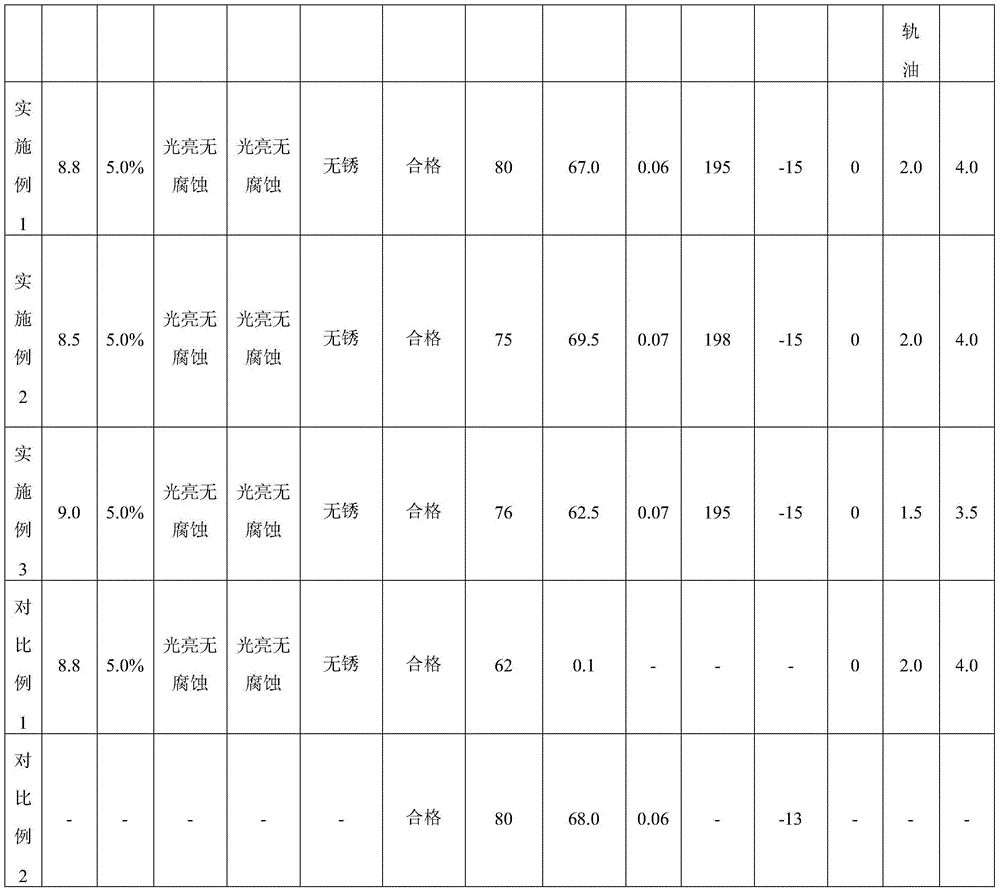

[0053] Table 1

[0054]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses water-soluble cutting oil applied to cutting work and guide rail lubrication. The water-soluble cutting oil comprises 40-60 parts by mass of mineral oil, 4-14 parts by weight of a pH adjusting agent, 5-15 parts by weight of an extreme-pressure lubricant, 15-30 parts by weight of an emulsifying agent, 0.1-3.5 parts by weight of a corrosion inhibitor, 0.1-2 parts by weight of a stabilizer, 0.01-0.2 part by weight of an antifoaming agent, 1-5 parts by weight of a sterilizing agent and 1-5 parts by weight of water. The water-soluble cutting coil applied to cutting work and guide rail lubrication according to the embodiment of the invention has high wear resistance and adhesion, and the extreme pressure performance of the cutting oil can meet the machining and guide rail working demands.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner KAIFENG AOKEBAO SPEICAL OIL AGENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com