Upright section for cabinet

A profile and column technology, applied in the field of column profiles for cabinets, can solve problems such as difficulty in ensuring sealing performance, low protection level, affecting internal electrical performance and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

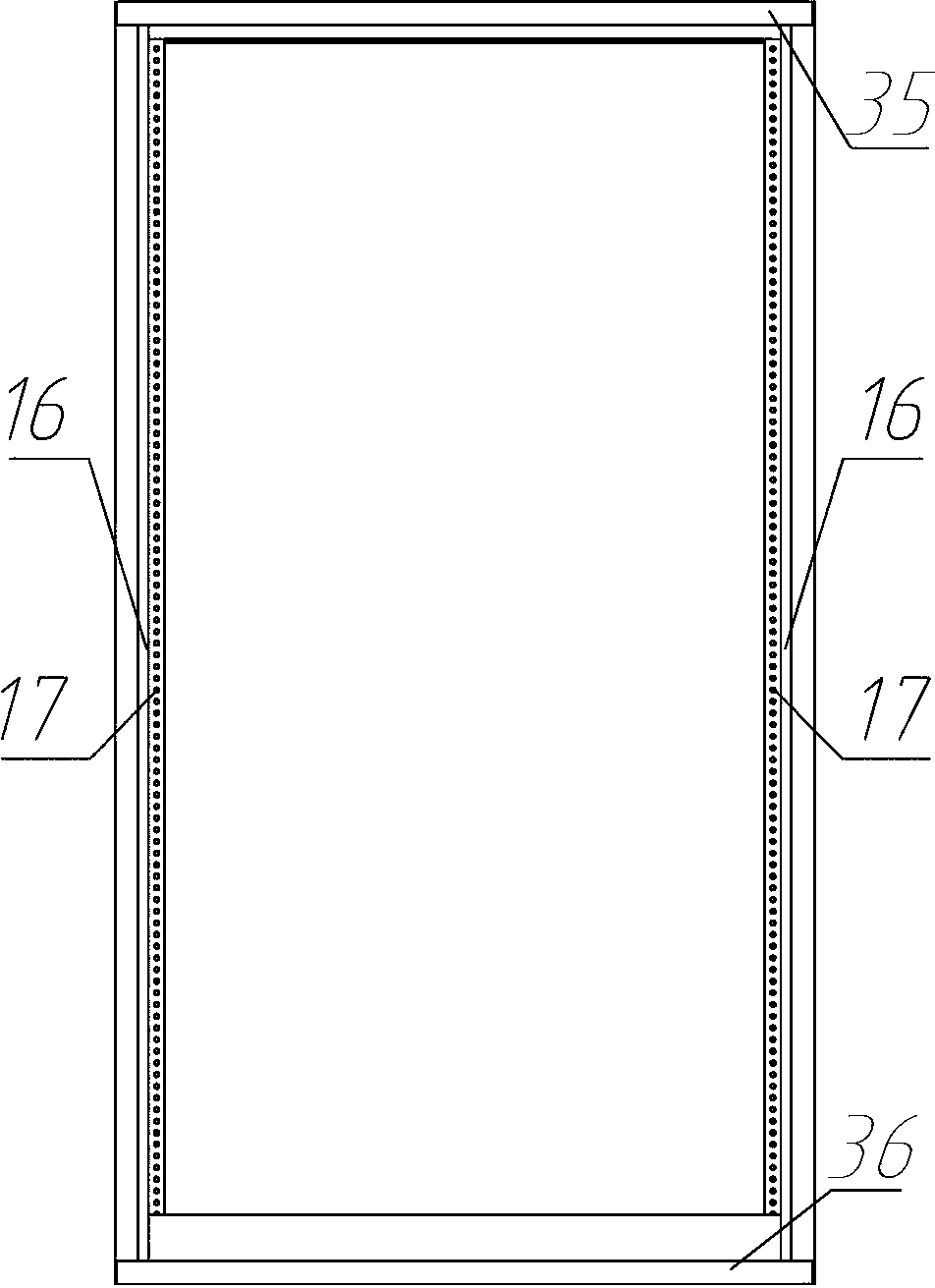

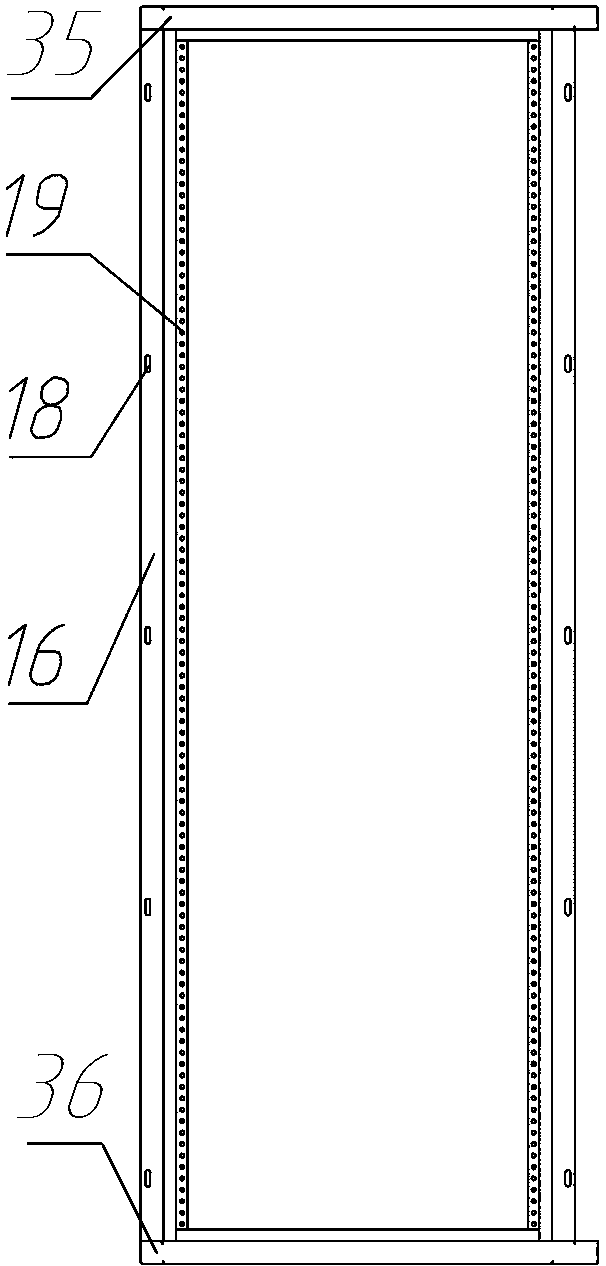

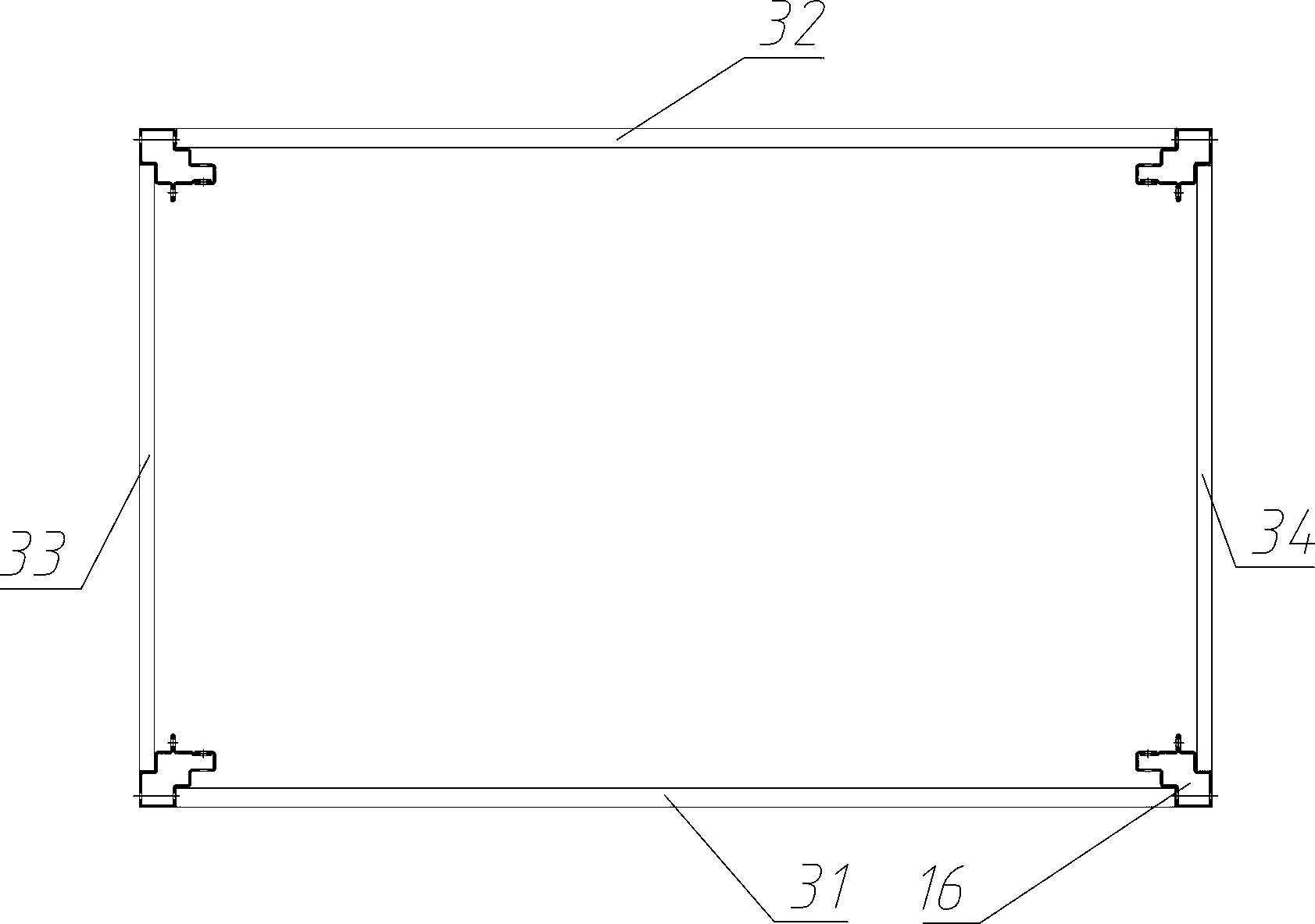

[0020] An example of a column profile for a cabinet in the present invention is Figure 1~Figure 6 As shown, it is a column profile used on the battery cabinet for energy storage. The cabinet is a rectangular parallelepiped as a whole, including four columns arranged in parallel, made of column profiles 16, used to support the internal frame of the cabinet, and also includes a front door panel 31, a rear door panel 32, a left side panel 33, a right side panel 34, a top panel Cover plate 35 and base plate 36, each upright column constitutes four vertical edges of cuboid cabinet.

[0021] The column profile 16 is specifically a special-shaped column-shaped fifteen-fold profile extending along the length direction, and has a plurality of outer walls formed by bending surfaces formed by continuous bending of corresponding plates from the beginning 20 to the end 21, It is defined that the beginning part of the plate extends along the left and right direction, and the section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com