A sealing device at the end of an air-cooled motor and a fan installation method

A technology for sealing devices and air-cooled motors, applied in electromechanical devices, cooling/ventilating devices, manufacturing motor generators, etc., can solve the problems of affecting the service life of motors, reducing the service life of bearings, polluting bearings, etc., achieving long service life, Strengthen the protective effect and facilitate the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

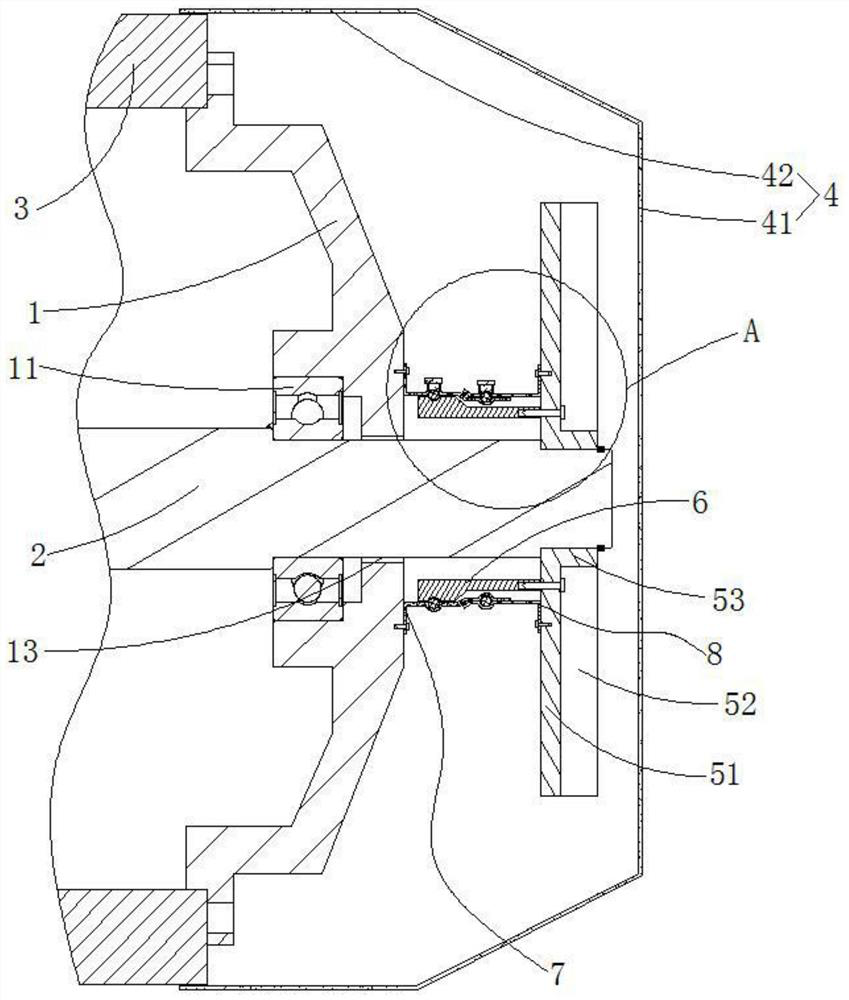

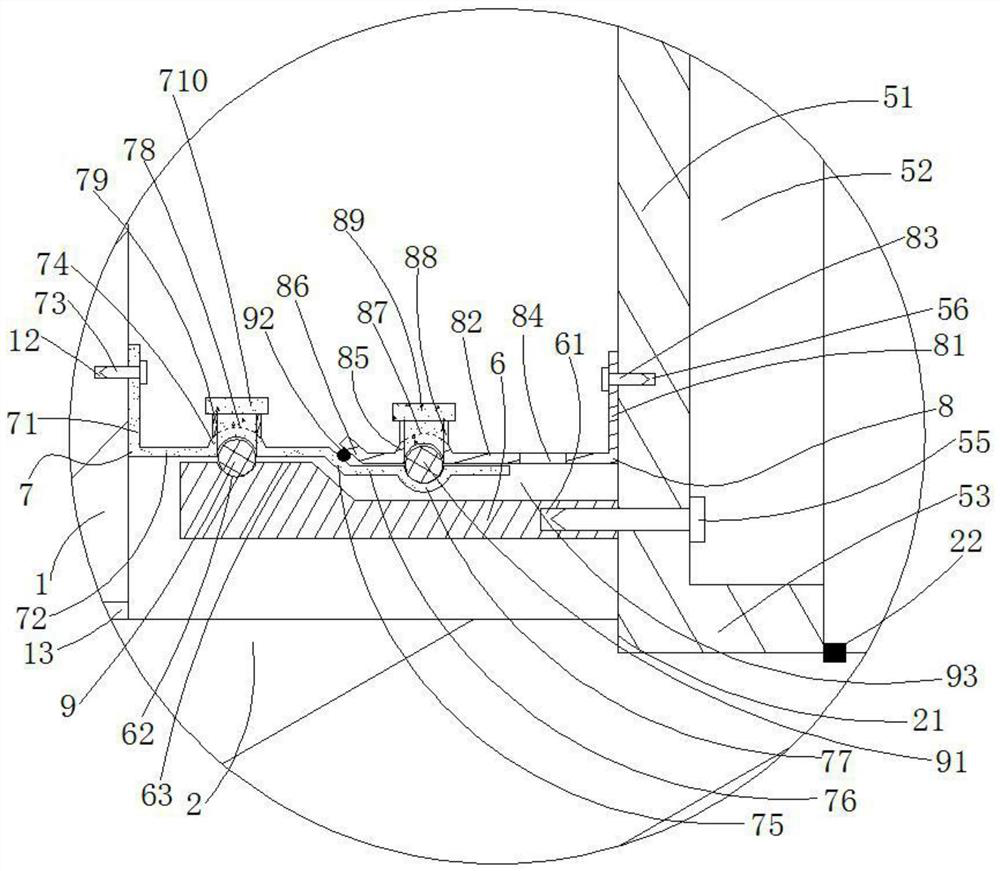

[0023] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further, in the present invention, refer to figure 1 , with the front end on the left and the back end on the right.

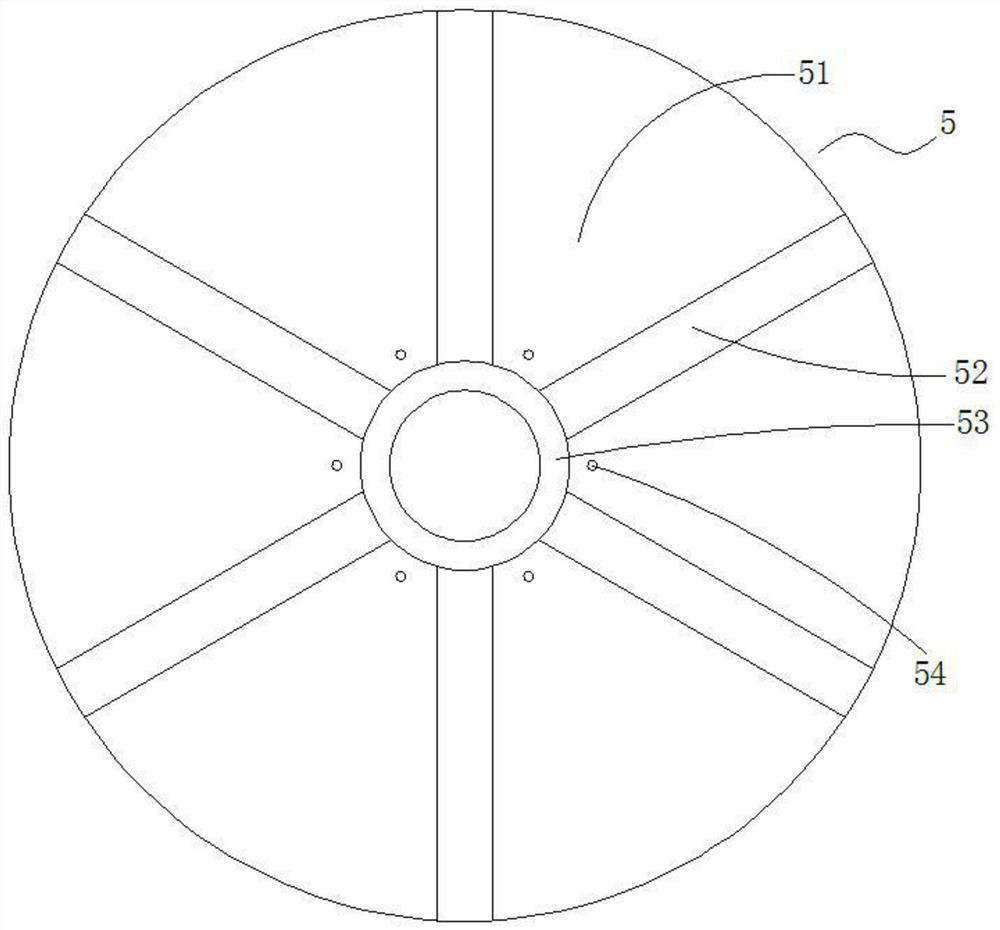

[0024] Such as Figure 1-Figure 3 As shown, a sealing device at the end of an air-cooled motor and a fan installation method, the air-cooled motor includes an end cover 1, a rotating shaft 2, a sealing device and a fan 5, and the air-cooled motor also includes a casing 3 and a windshield 4 (here The parts of known motors such as stator and rotor are omitted), the specific installation means of end cover 1, rotating shaft 2, casing 3, wind cover 4 and fan 5 can refer to the current prior art, and described end cover 1 is fixed Connected to the rear end surface of the casing 3, the rotating shaft 2 passes through the end cover 1 and the part of the rotating shaft 2 exposed outside the end cover 1 is connected with a fan 5, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com