Cell pack, device and method for manufacturing cell pack

A technology for manufacturing devices and battery packs, which is applied to battery pack components, battery covers/end covers, circuits, etc., and can solve problems such as increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

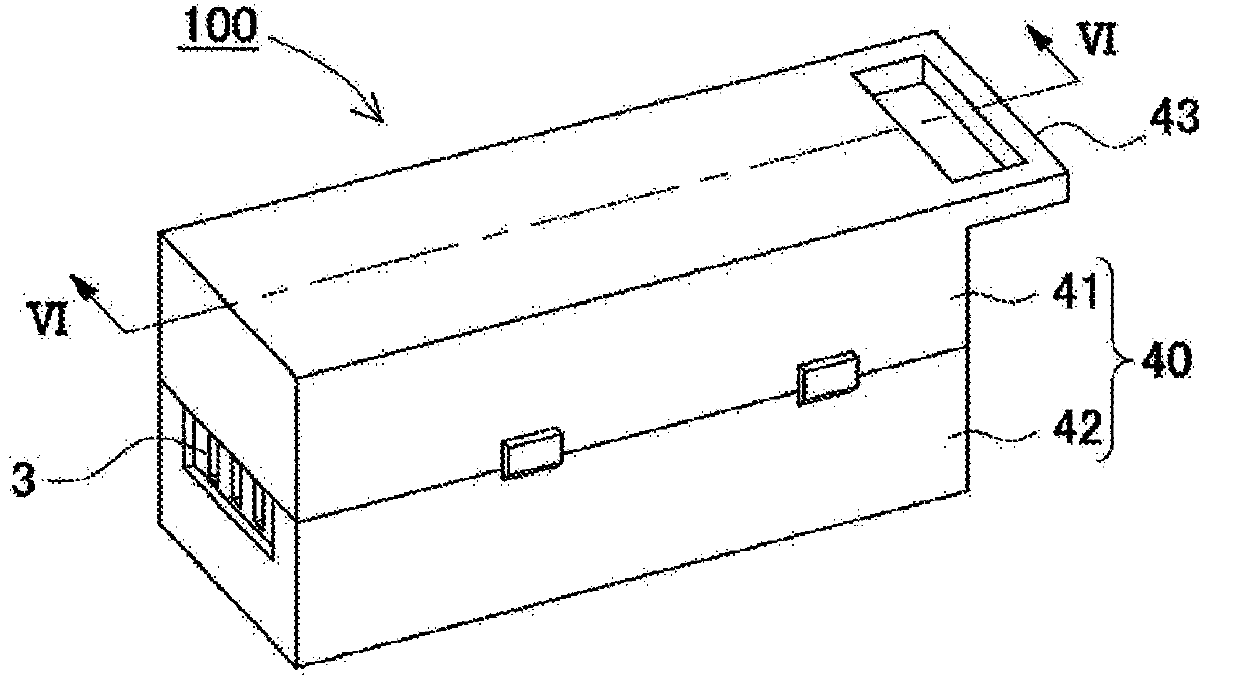

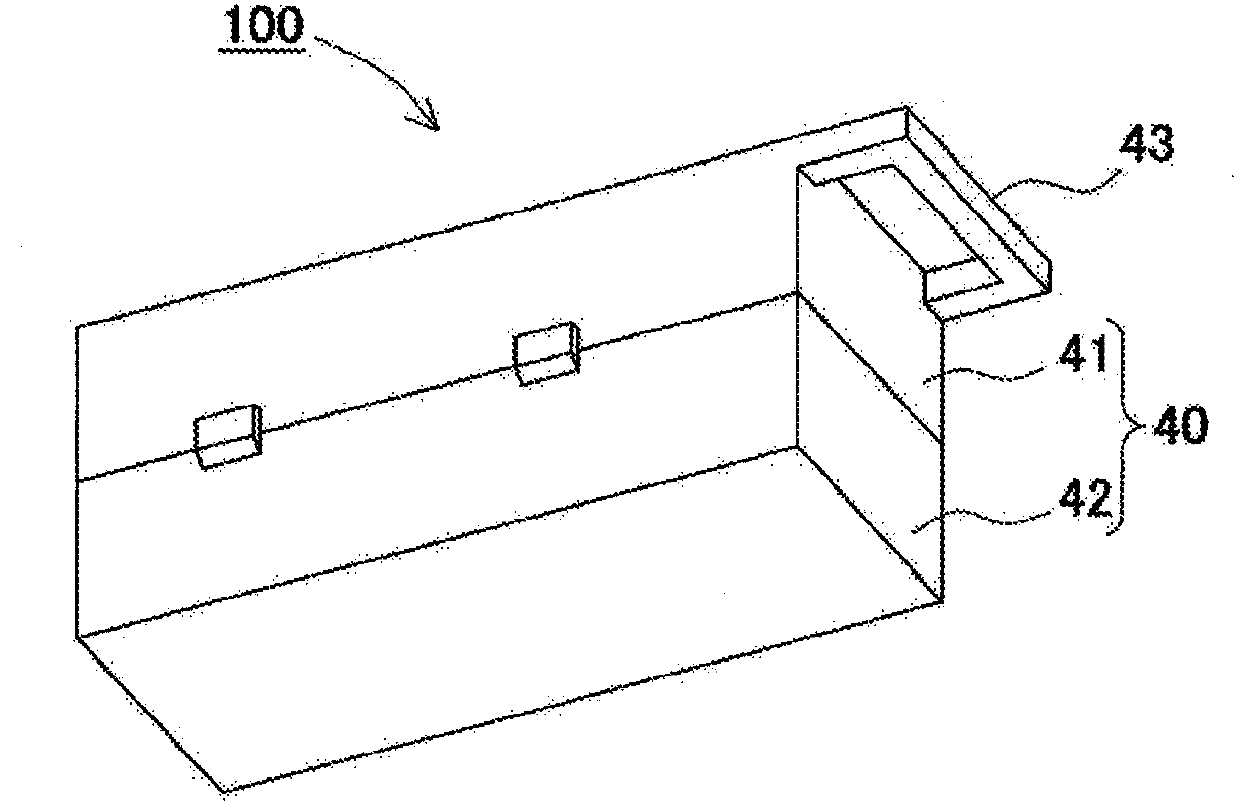

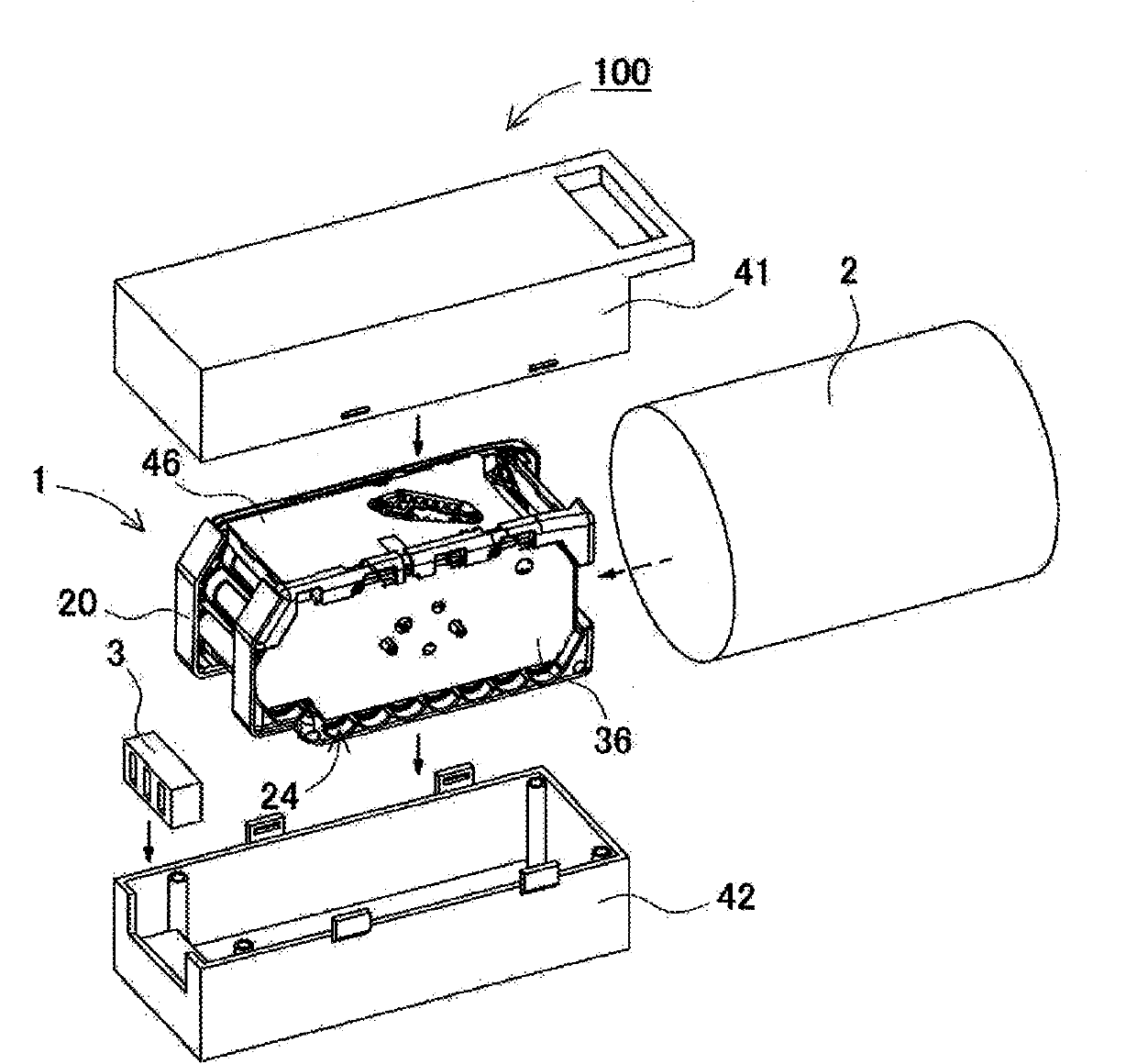

[0079] Figure 1 to Figure 5 An example of application to a battery pack for an assist bicycle is shown as the battery pack 100 according to Embodiment 1 of the present invention. These figures represent the following, respectively: figure 1 is a perspective view showing the appearance of the battery pack 100 of the first embodiment; figure 2 Viewed obliquely from the rear side figure 1 A perspective view of the appearance of the battery pack 100; image 3 yes figure 1 An exploded perspective view of the battery pack 100; Figure 4 It is self image 3 The state of further decomposed the exploded perspective view of the state of the battery part 1; Figure 5 Viewed obliquely from the rear side Figure 4 The external perspective view and enlarged view of the battery pack 100; Figure 6 yes figure 1 Sectional view of VI-VI. The battery pack 100 shown in these figures is composed of a case 40 and a battery unit 1 housed inside. Such as Figure 1 ~ Figure 4 As show...

Embodiment 2

[0108] First, the battery pack 200 of Example 2 is shown in Figure 11 ~ Figure 12 . These figures represent the following, respectively: Figure 11 It is a cross-sectional view and a partially enlarged view of the battery pack 200 of Embodiment 2; Figure 12 is said to be Figure 11 An exploded cross-sectional view of a state in which the lower case 42B is separated from the battery unit 1B. The external appearance of the battery pack 200 is the same as that of the first embodiment, but the internal battery components are different. Specifically, battery unit 1B in Example 2 uses a total of 40 battery cells 10 connected in series×4 in parallel. In this second embodiment, the case-side protrusion 28B of the battery case 20B and the case-side rib 48B of the lower case 42B are offset so as to be located at positions not to interfere with each other when the battery part 1B is inserted into the lower case 42B. . Thus, it is possible to Figure 11 , Figure 12 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com