Fixing device for automobile processing

A fixing device and automobile technology, applied in the fields of automobile painting, automobile and automobile manufacturing, can solve the problems of time-consuming and laborious, and achieve the effect of flexible height adjustment, stable fixing, and multi-angle fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

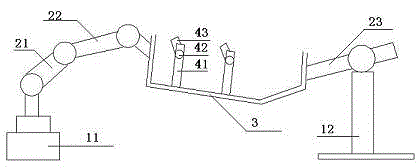

[0024] Such as figure 1 As shown, the fixing frame for automobile processing, the fixing device includes a base, a processing tank 3 fixed on the base, and also includes rotating arms 21, 22, 23, and the rotating arms are fixedly installed on the base and the processing tank 3 Between, the base is divided into a left base 11 and a right base 12, the rotating arms 21, 22 are fixedly mounted on the left base 11, and the rotating arm 23 is fixedly mounted on the right base 12.

Embodiment 2

[0026] On the basis of Embodiment 1, the rotating arm fixed to the left base 11 includes two groups, namely the first rotating arm 21 and the second rotating arm 22, and the rotating arm fixed to the right base 12 is the third rotating arm twenty three.

[0027] When the height and angle of the processing tank 3 need to be adjusted, the shafts of the first rotating arm 21 , the second rotating arm 22 and the third rotating arm 23 can be used to realize the height and angle adjustment of the processing tank 3 .

Embodiment 3

[0029] A supporting frame 41 , a limiting block 43 and a rotary joint 42 for connecting the limiting block 43 to the supporting frame 41 are also fixed in the processing 3 groove. Through the structural design of the rotary joint 42, when the supporting frame 41 is under force, the limiting block 43 moves, so as to limit the sliding of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com