Single-operation washing heavy-duty film coating device

A single operation, liquid washing technology, applied in the field of detergent packaging, can solve problems such as toilet blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

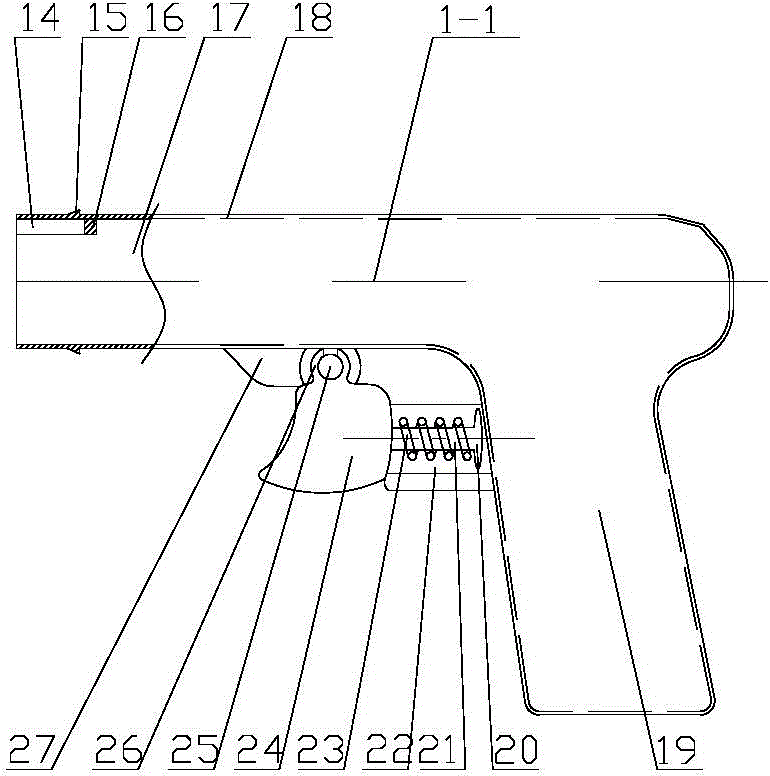

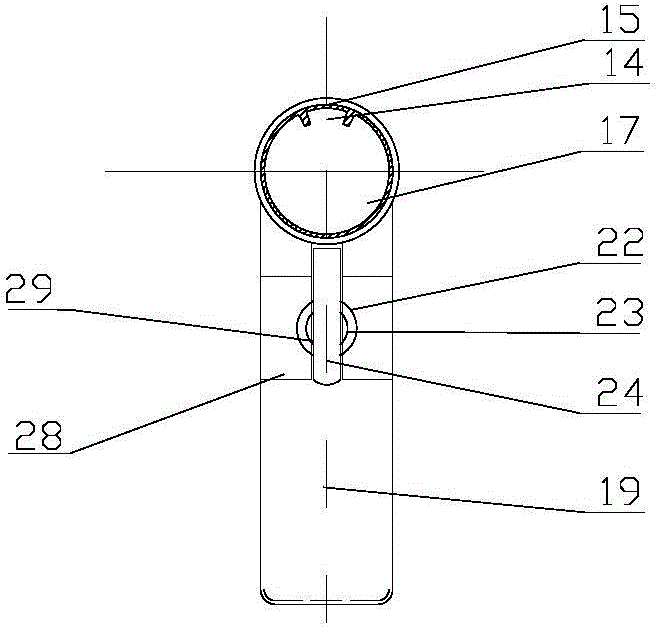

[0047] 1. Single-operating liquid washing heavy-scaling film coating device, including: single-operating liquid washing heavy-scaling film coating device main body 1-1, plugging 1-2, extrusion cap 1-3;

[0048] The main body 1-1 of the single-operation liquid washing heavy-duty film coating device includes a U-shaped keyway 14, an extrusion cap convex card 15, a plugging over-stroke card 16, a washing liquid filling chamber 17, a gun barrel 18, a grip handle 19, a squeeze Press bolt extrusion curved surface 20, extrusion bolt 21, extrusion bolt cavity 22, extrusion bolt compression spring 23, trigger 24, trigger rotation shaft 25, trigger holding card 26, trigger fixing block 27, fixed splint 28, splint trigger seam 29,

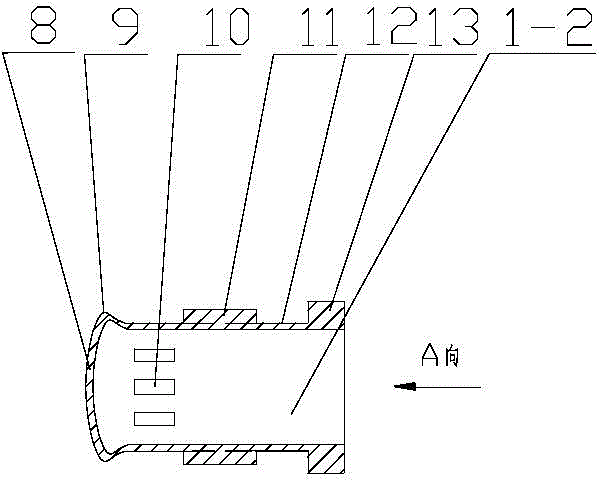

[0049] Plugging 1-2 includes curved surface plugging 8, curved surface plugging variable diameter convex 9, ring wall plugging extrusion hole 10, plugging external thread 11, plugging middle small-diameter tube 12, plugging fixed spline 13,

[0050] Extrusio...

Embodiment 2

[0069] 1. Single-operating liquid washing heavy-scaling film coating device, including: single-operating liquid washing heavy-scaling film coating device main body 1-1, plugging 1-2, extrusion cap 1-3;

[0070] The main body 1-1 of the single-operation liquid washing heavy-duty film coating device includes a U-shaped keyway 14, an extrusion cap convex card 15, a plugging over-stroke card 16, a washing liquid filling chamber 17, a gun barrel 18, a grip handle 19, a squeeze Press bolt extrusion curved surface 20, extrusion bolt 21, extrusion bolt cavity 22, extrusion bolt compression spring 23, trigger 24, trigger rotation shaft 25, trigger holding card 26, trigger fixing block 27, fixed splint 28, splint trigger seam 29,

[0071] Plugging 1-2 includes curved surface plugging 8, curved surface plugging variable diameter convex 9, ring wall plugging extrusion hole 10, plugging external thread 11, plugging middle small-diameter tube 12, plugging fixed spline 13,

[0072] Extrusio...

Embodiment 3

[0091] 1. Single-operating liquid washing heavy-scaling film coating device, including: single-operating liquid washing heavy-scaling film coating device main body 1-1, plugging 1-2, extrusion cap 1-3;

[0092] The main body 1-1 of the single-operation liquid washing heavy-duty film coating device includes a U-shaped keyway 14, an extrusion cap convex card 15, a plugging over-stroke card 16, a washing liquid filling chamber 17, a gun barrel 18, a grip handle 19, a squeeze Press bolt extrusion curved surface 20, extrusion bolt 21, extrusion bolt cavity 22, extrusion bolt compression spring 23, trigger 24, trigger rotation shaft 25, trigger holding card 26, trigger fixing block 27, fixed splint 28, splint trigger seam 29,

[0093] Plugging 1-2 includes curved surface plugging 8, curved surface plugging variable diameter convex 9, ring wall plugging extrusion hole 10, plugging external thread 11, plugging middle small-diameter tube 12, plugging fixed spline 13,

[0094] Extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com