Rotary transfer scraper conveyor

A scraper conveyor and rotating mechanism technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems that the scraper conveyor cannot guarantee the continuous conveying of materials, reduce the continuous operation efficiency, etc., and achieve convenient assembly and disassembly. Fast, simple structure, flexible and stable rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

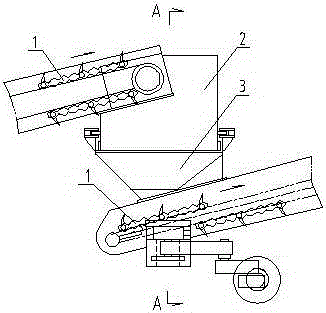

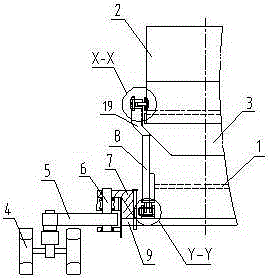

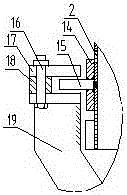

[0022] Example 1, in figure 1 , figure 2 , image 3 with Figure 4 Among them, the rotary transfer scraper conveyor includes a scraper conveyor body 1, a travel steering wheel arranged at the lower part of the front end of the scraper conveyor body, and a rotating device arranged between the front part of the conveyor body and the rear part of the conveyor, The walking steering wheel is movably connected with the two ends of the beam 9, and the walking steering wheel includes a universal wheel 4, a connecting rod 5 and a vertical shaft 6, and one end of the connecting rod is movably connected with the universal wheel, and the other end is connected to the cantilever through the rotating shaft. 7 are movably connected, and the cantilever is connected with one end of the beam. The rotating device is a cylinder rotating mechanism, and the cylinder rotating mechanism includes an upper cylinder 2, a lower cylinder 3 and a rotating sleeve connecting the upper cylinder and the lo...

Embodiment 2

[0023] Example 2, in Figure 5 , Image 6 , Figure 7 with Figure 8Among them, a rotary reloading scraper conveyor with a bogie structure includes a scraper conveyor body 1 and a walking steering wheel arranged at the lower part of the front end of the scraper conveyor body, and a scraper conveyor body and a scraper conveyor The rotating device between the rear parts of the conveyor, the walking universal wheels include universal wheels 4, the universal wheels are movably connected with the two ends of the crossbeam 9, and a blanking tray 2a is arranged at the rear of the scraper conveyor, and on the scraper The front part of the conveyor is provided with a beveled and annular receiving tray 3a. The rotating device is a bogie mechanism, and the bogie mechanism includes a joint, a load beam 5a and a rotary device. It is supported on both ends of the load-bearing beam, and the load-bearing beam is movably connected with the beam through a slewing device. The joint includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com