Grinding jig for mobile phone parts

A technology of parts and jigs, which is applied in the field of grinding jigs, can solve the problems of low work efficiency of staff, and achieve the effects of stable and uniform adsorption force, time saving, and convenient pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

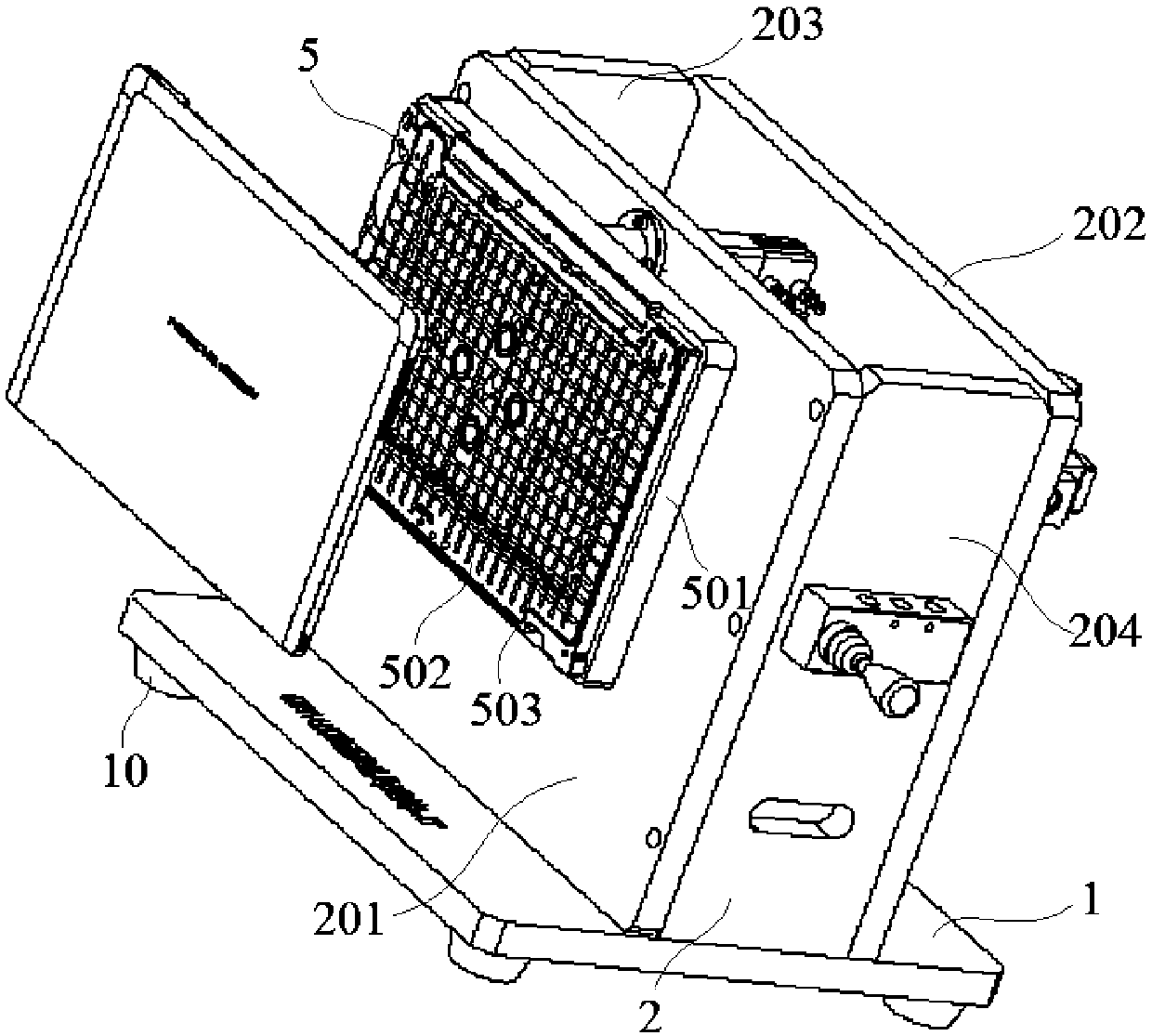

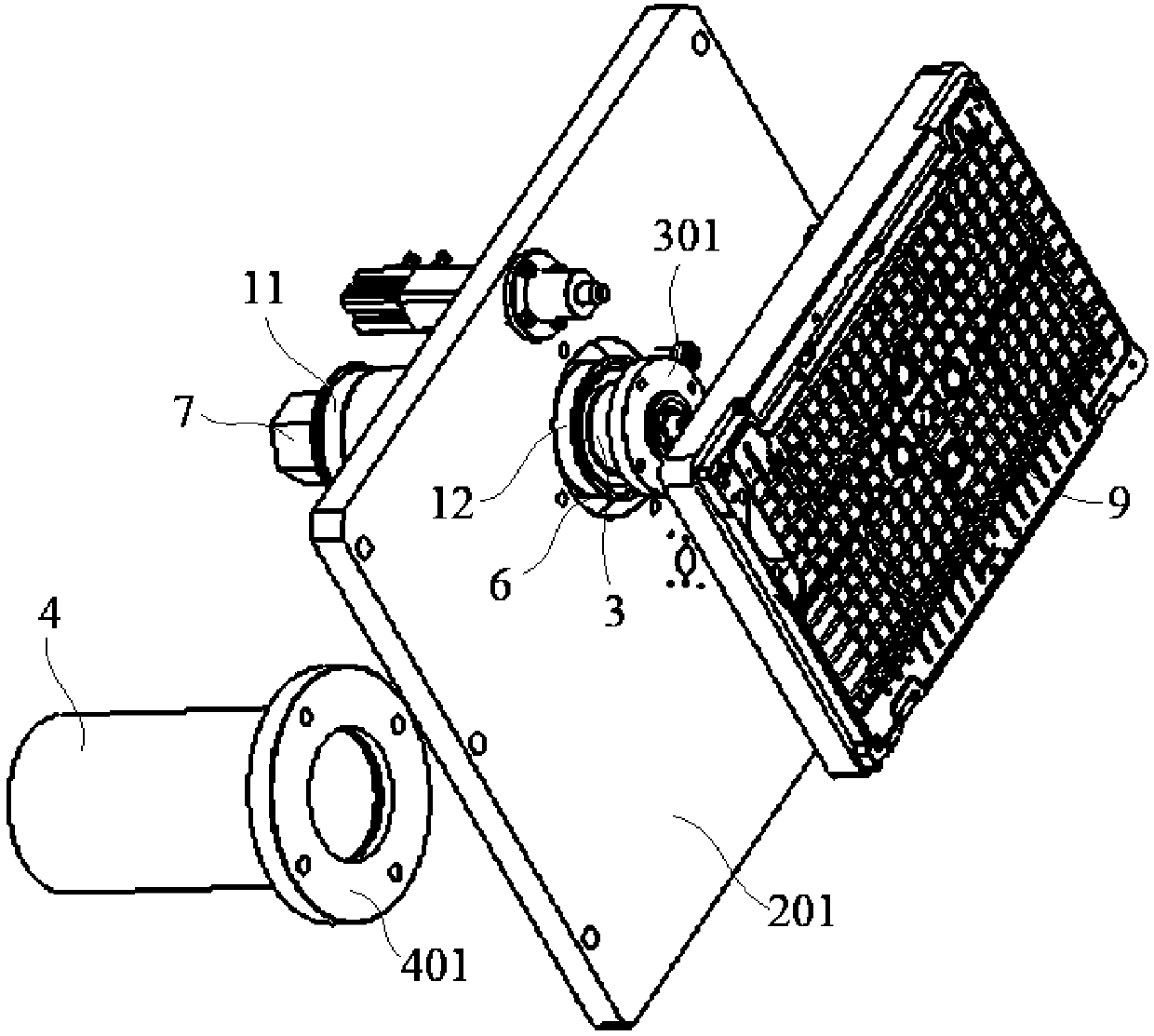

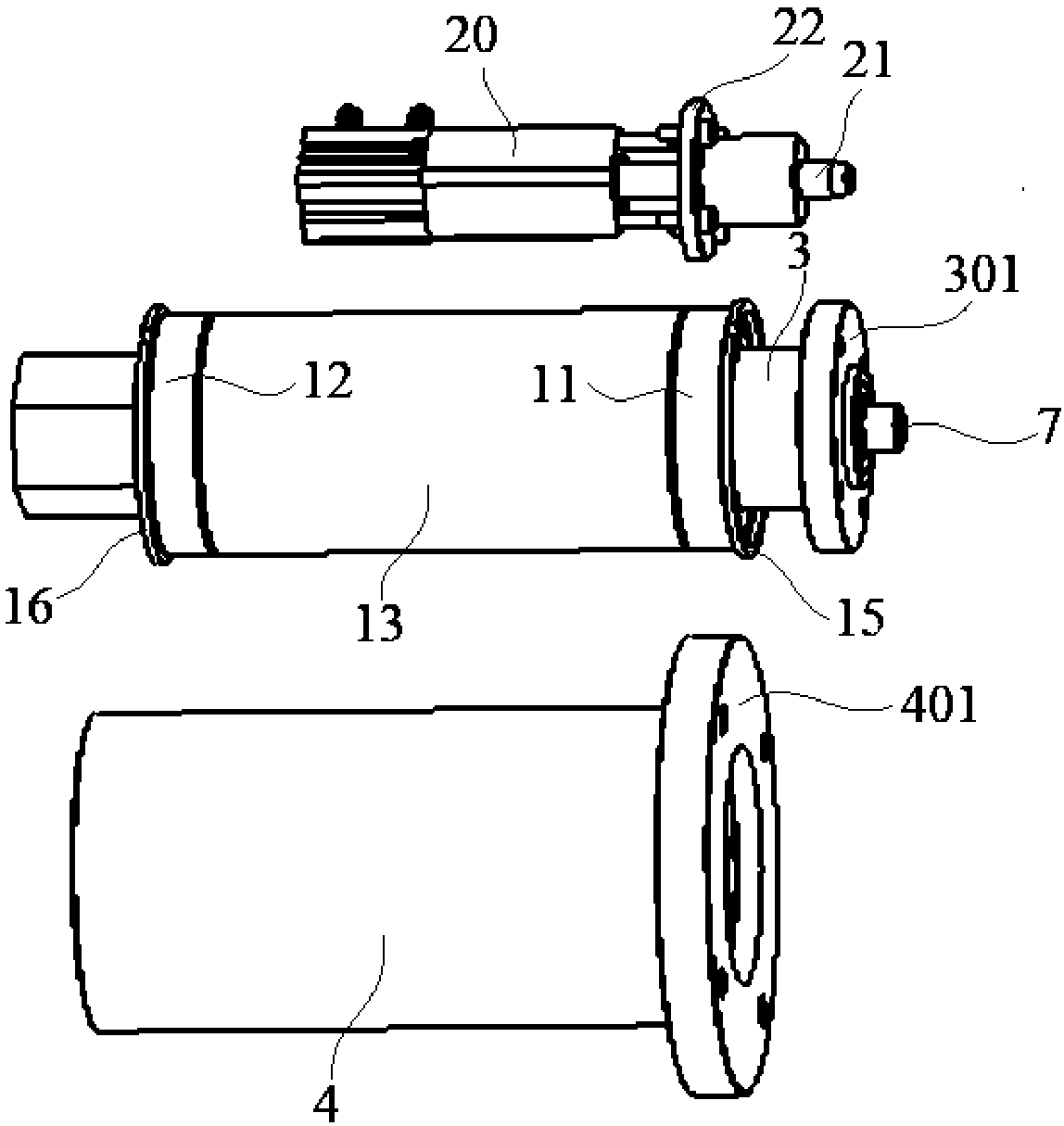

[0025] Embodiment 1: a kind of polishing jig for mobile phone parts, including base plate 1, support 2, main shaft 3, axle sleeve 4 and the fixing plate 5 for fixing product, described support 2 is fixed on the base plate 1, described The shaft sleeve 4 is fixedly connected with the bracket 2, and the main shaft 3 is embedded in the shaft sleeve 4 and connected with the fixed plate 5;

[0026] Described support 2 is made up of front side plate 201, rear side plate 202, left side plate 203 and right side plate 204, and described front side plate 201 and rear side plate 202 are arranged in parallel and on front side plate 201 and rear side plate 202 Both have a through hole 6 for the main shaft 3 to pass through. One end of the shaft sleeve 4 has a flange portion 401, and the other end of the shaft sleeve 4 passes through the through hole 6 of the front side plate 201 and the rear side plate 202 and passes through the protrusion. The edge portion 401 is fixedly connected to the ...

Embodiment 2

[0031] Embodiment 2: a kind of polishing tool for mobile phone parts, including base plate 1, support 2, main shaft 3, axle sleeve 4 and fixed plate 5 for fixing the product, described support 2 is fixed on the base plate 1, and described The shaft sleeve 4 is fixedly connected with the bracket 2, and the main shaft 3 is embedded in the shaft sleeve 4 and connected with the fixed plate 5;

[0032] Described support 2 is made up of front side plate 201, rear side plate 202, left side plate 203 and right side plate 204, and described front side plate 201 and rear side plate 202 are arranged in parallel and on front side plate 201 and rear side plate 202 Both have a through hole 6 for the main shaft 3 to pass through. One end of the shaft sleeve 4 has a flange portion 401, and the other end of the shaft sleeve 4 passes through the through hole 6 of the front side plate 201 and the rear side plate 202 and passes through the protrusion. The edge portion 401 is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com