Optical film delivery method and device using same

An optical film and conveying device technology, which is applied in the directions of transportation and packaging, sending objects, and thin material processing, can solve the problems of reducing the quality of the conveyed objects, and achieve the effect of suppressing the quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the present invention, the optical member is not particularly limited as long as it is a flexible strip-shaped functional film such as a polarizing film, a retardation film, and a brightness enhancement film. case is described as an example.

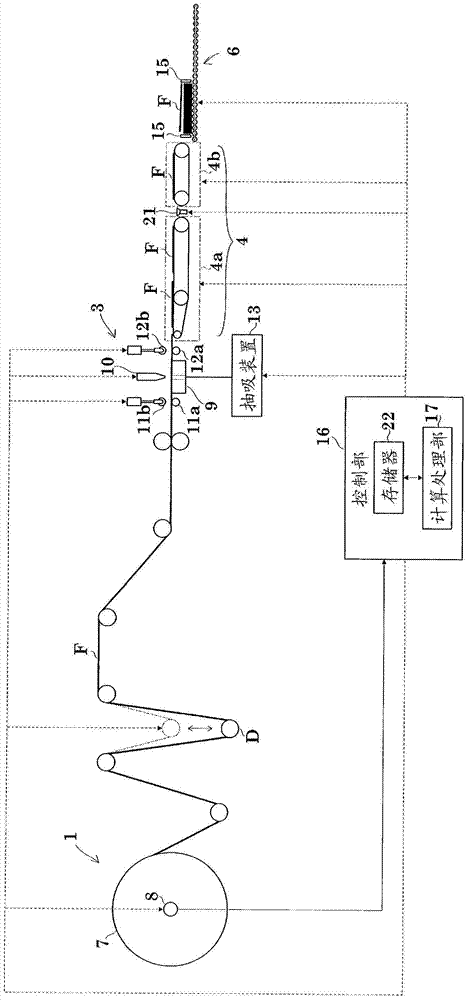

[0028] figure 1 It shows the schematic structure of the optical film cutting apparatus which not only implements the optical film cutting method of this invention, but also includes the process before stacking the cut optical film and carrying out the optical film.

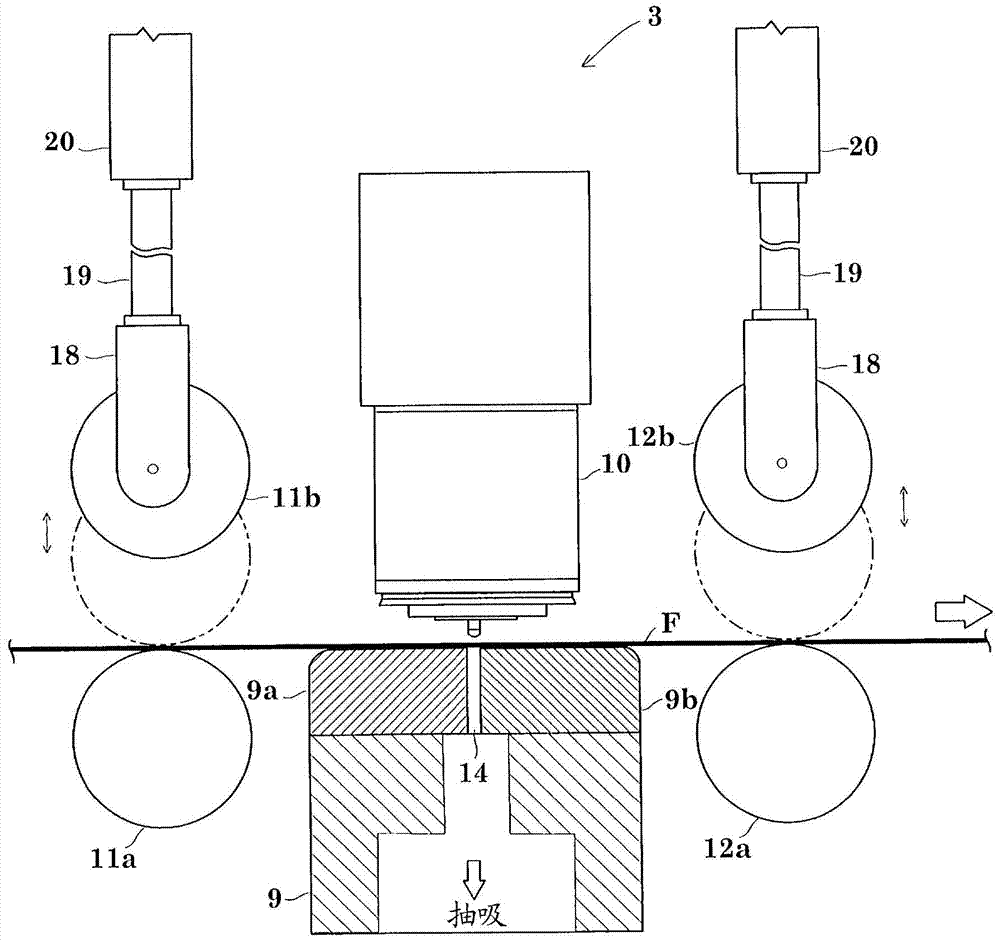

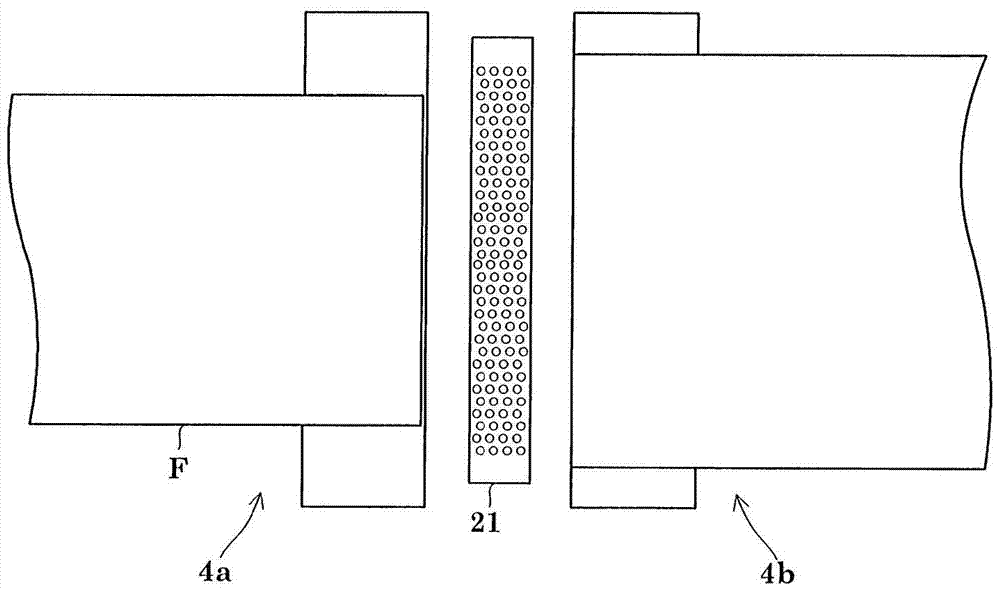

[0029] The apparatus of this embodiment consists of a film supply unit 1 that discharges and supplies the polarizing film F, a cutting mechanism 3 that cuts the polarizing film F into a film having a predetermined length in the conveying direction, and conveys the polarized light after cutting at the end of the conveying path. The conveyance mechanism 4 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com