Film forming apparatus, film forming method and manufacturing method of electronic device

A film-forming device and film-forming object technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven film quality, no record of film-forming control, and film-forming quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

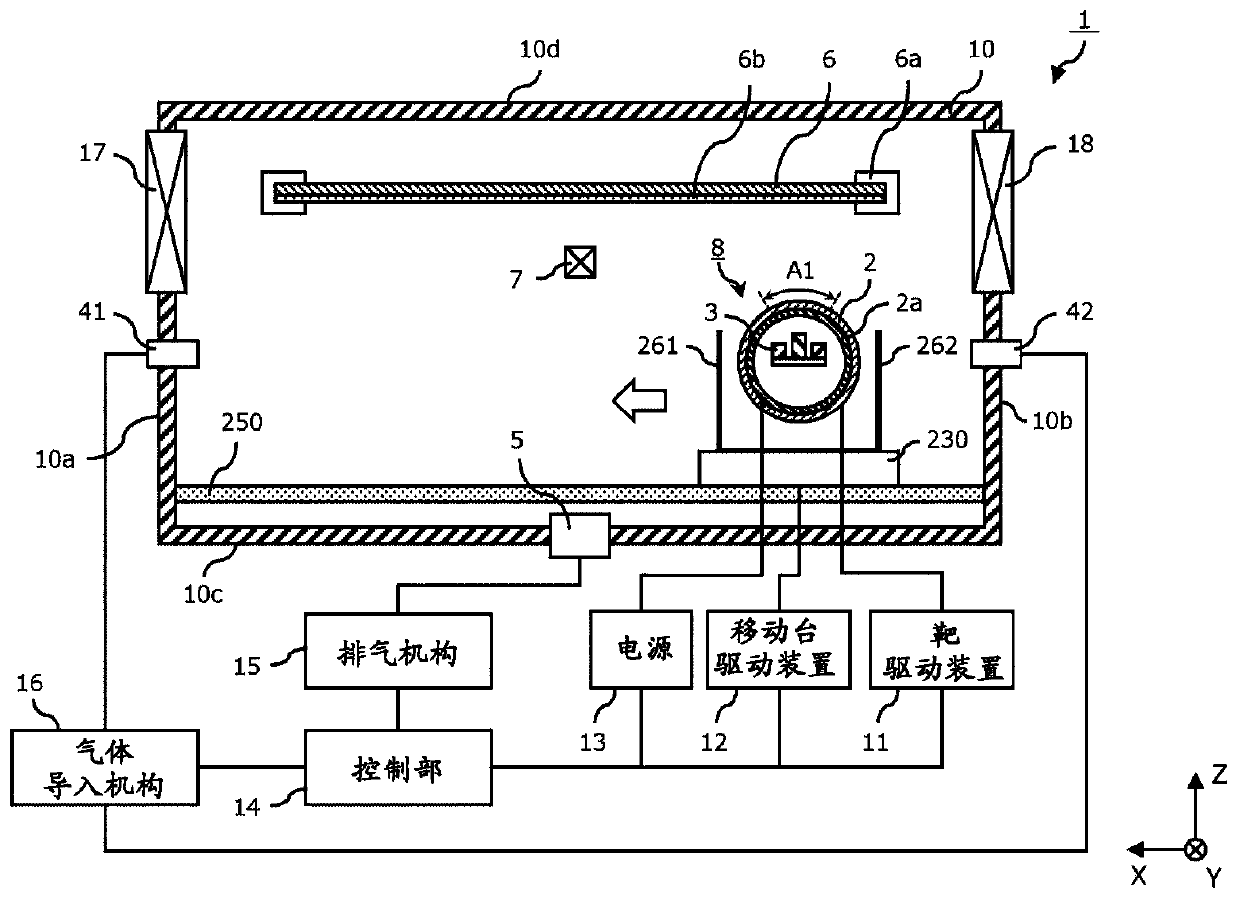

[0036] The basic configuration of the film forming apparatus 1 according to Embodiment 1 will be described with reference to the drawings. The film forming apparatus 1 is used to deposit and form a thin film on a substrate (including a laminated body formed on the substrate) in the manufacture of various electronic devices such as semiconductor devices, magnetic devices, and electronic components, and optical components. More specifically, the film forming apparatus 1 is preferably used in the manufacture of electronic devices such as light emitting elements, photoelectric conversion elements, and touch panels. Among them, the film-forming apparatus 1 of the present embodiment is particularly preferably used in the production of organic light-emitting elements such as organic EL (Electro Luminescence: electroluminescence) elements, and organic photoelectric conversion elements such as organic thin-film solar cells. The electronic device in the present invention also includes a...

Embodiment approach 2

[0070] Next, Embodiment 2 of the present invention will be described. Hereinafter, differences from Embodiment 1 will be mainly described, and the same components will be given the same reference numerals to simplify the description.

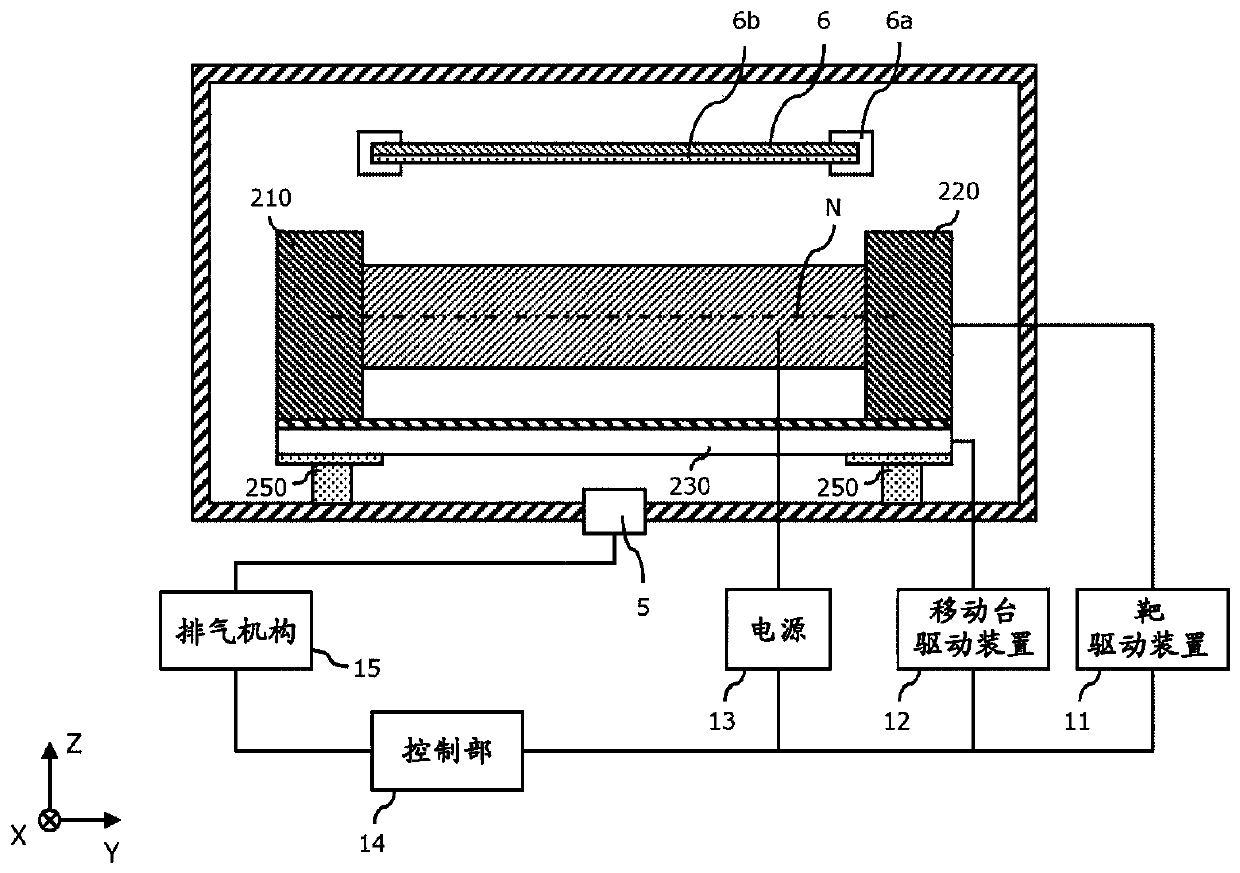

[0071] Figure 4 (a) shows the film formation apparatus 1 of this embodiment. In the film forming apparatus 1 , instead of using a rotary cathode unit using a cylindrical target, a planar cathode unit 308 using a flat plate-shaped target 302 is used. The planar cathode unit 308 has a target 302 arranged parallel to the object 6 to be film-formed, and the magnet unit 3 as a magnetic field generating means is arranged on the opposite side of the target 302 to the object 6 to be film-formed. In addition, a backing plate 302 a to which electric power is applied from the power source 13 is provided on the surface of the target 302 opposite to the object 6 to be film-formed. Sputtered particles are emitted from the sputtering region A1 by applying ...

Embodiment approach 3

[0076] Next, Embodiment 3 of the present invention will be described. Hereinafter, differences from the above-described embodiments will be mainly described, and the same components will be given the same reference numerals to simplify the description.

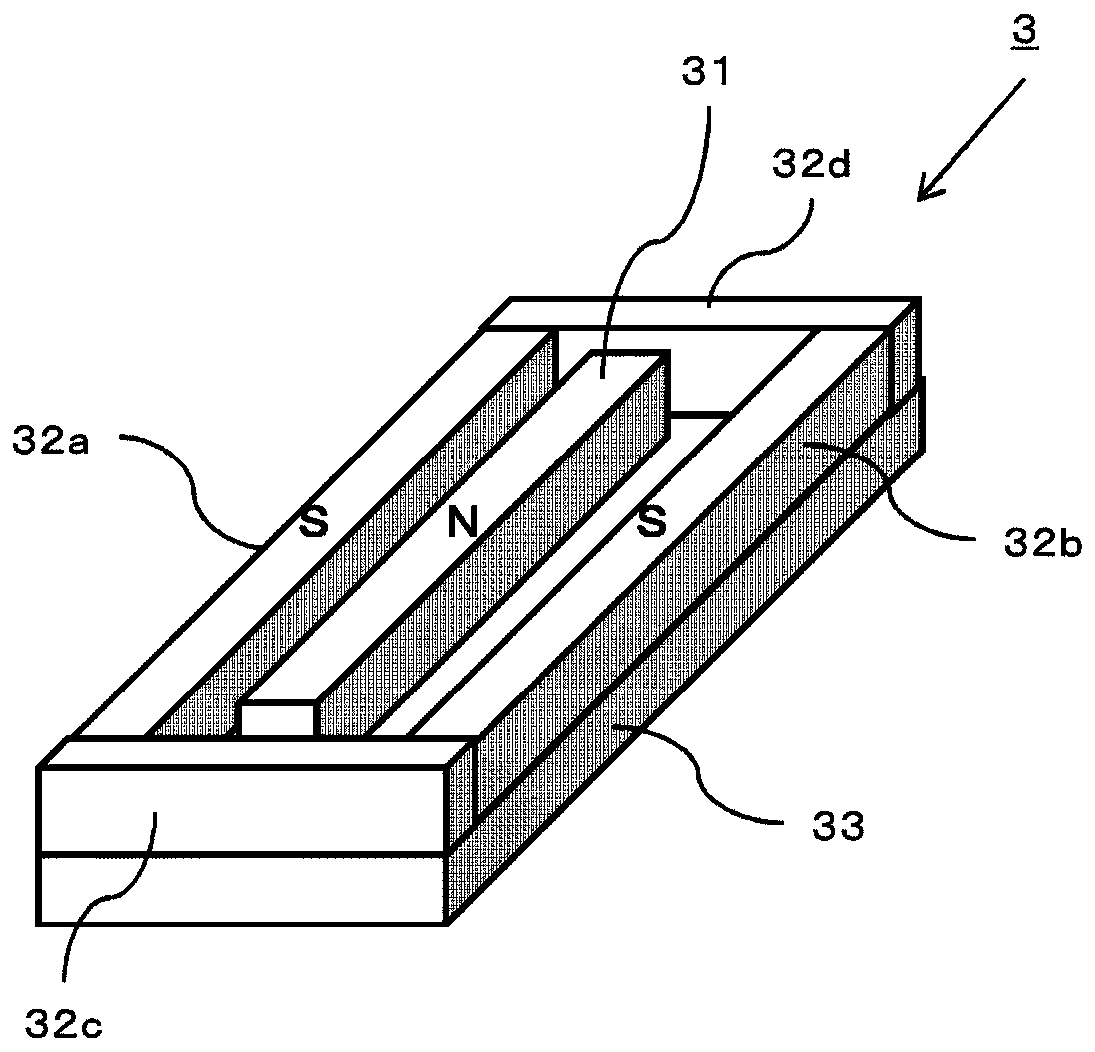

[0077] Figure 5 The film formation apparatus 1 of this embodiment is shown. in the above Figure 4 (b)~ Figure 4 In (d), the magnet unit 3 in the planar cathode unit can move relative to the target 302 . In the present embodiment, the flat plate-shaped target 402 is larger than the film formation target object 6 in both the X-axis direction and the Y-axis direction, and is fixedly installed with respect to the chamber 10 . In addition, the magnet unit 3 as a magnetic field generating mechanism moves relative to the target 402 fixed to the chamber 10 (ie, relative to the chamber 10 ). Accompanied by this, the sputtering region A1 of the target 402 from which the target particles are emitted also moves relative to the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com