A non-damping collision testing machine

A collision test and non-damping technology, which is applied in the field of mechanical engineering, can solve problems such as inconsistent collision conditions of objects, and achieve the effect of removing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

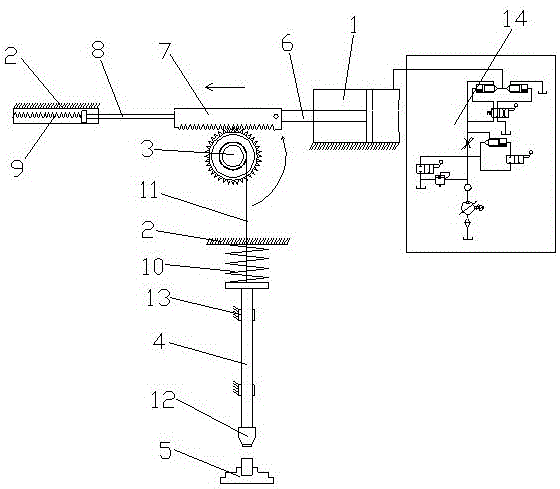

[0015] The present invention is described below in conjunction with accompanying drawing.

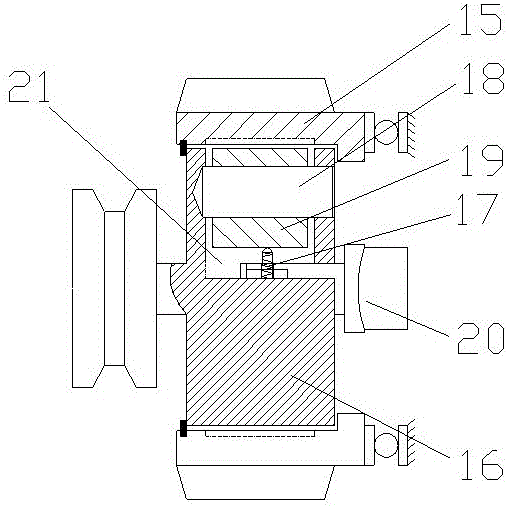

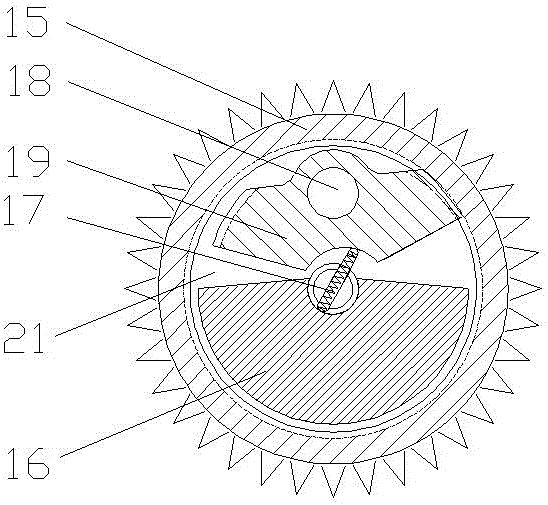

[0016] as attached Figure 1-4 Shown is a kind of non-damping impact testing machine according to the present invention, comprising a plunger cylinder 1, a bracket 2, a gear 3, a power storage spring 10, an impact push rod 4 and a fixture table 5; the plunger cylinder 1 A rack 7 is connected to the piston rod 6; the rack 7 is arranged above the gear 3 and meshed with the gear 3, and the gear 3 is driven to rotate by the movement of the rack 7; the gear 3 includes a gear housing 15 and a runner 16 The runner 16 is arranged in the gear housing 15 and can rotate in the gear housing 15; the runner 16 is provided with a groove 21; Tooth block 19; the bottom of the inner tooth block 19 is arranged in an arc; the central axis of the runner 16 is provided with a spring rod 17; one end of the spring rod 17 extends into the arc of the inner gear block 19 to control the runner 16 and the gear ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com