Battery pack bottom anti-collision capability evaluation test method

A test method and battery pack technology, applied in the testing of machines/structural components, components of electrical measuring instruments, measuring electricity, etc., can solve problems such as missing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

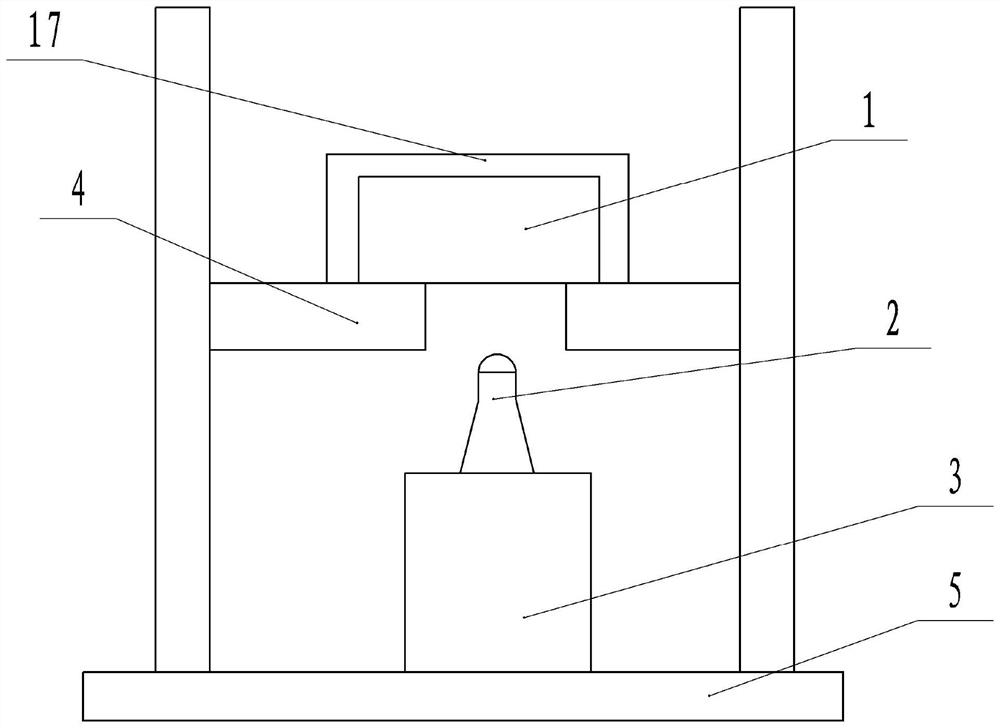

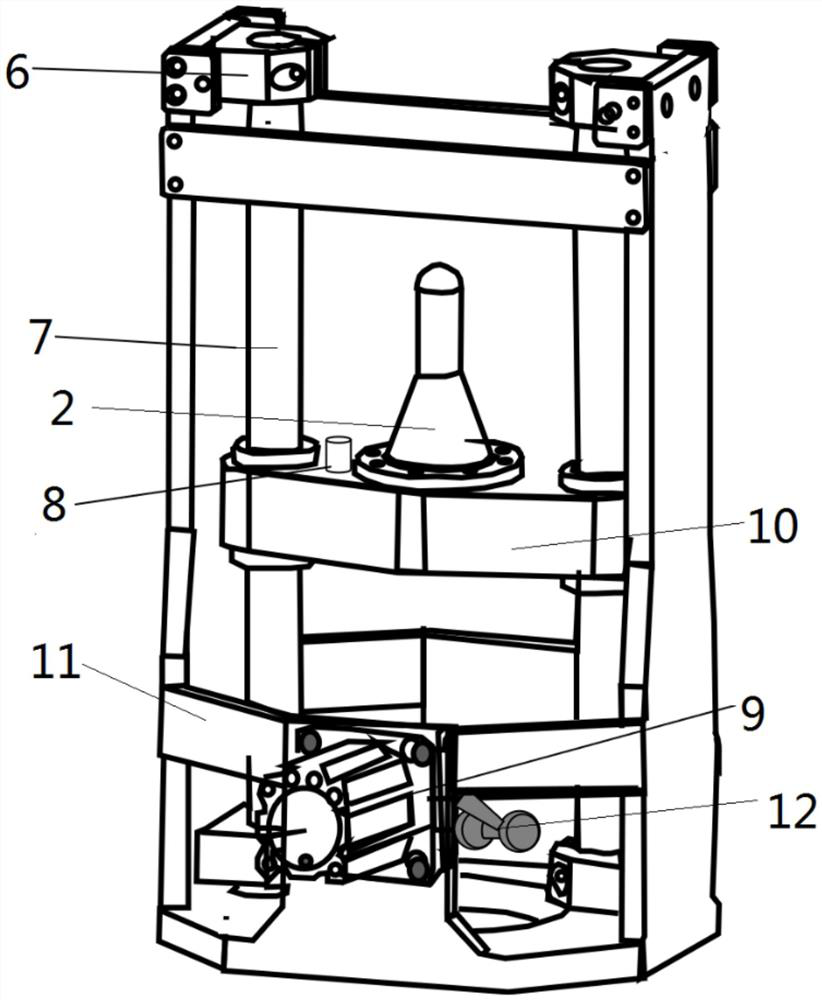

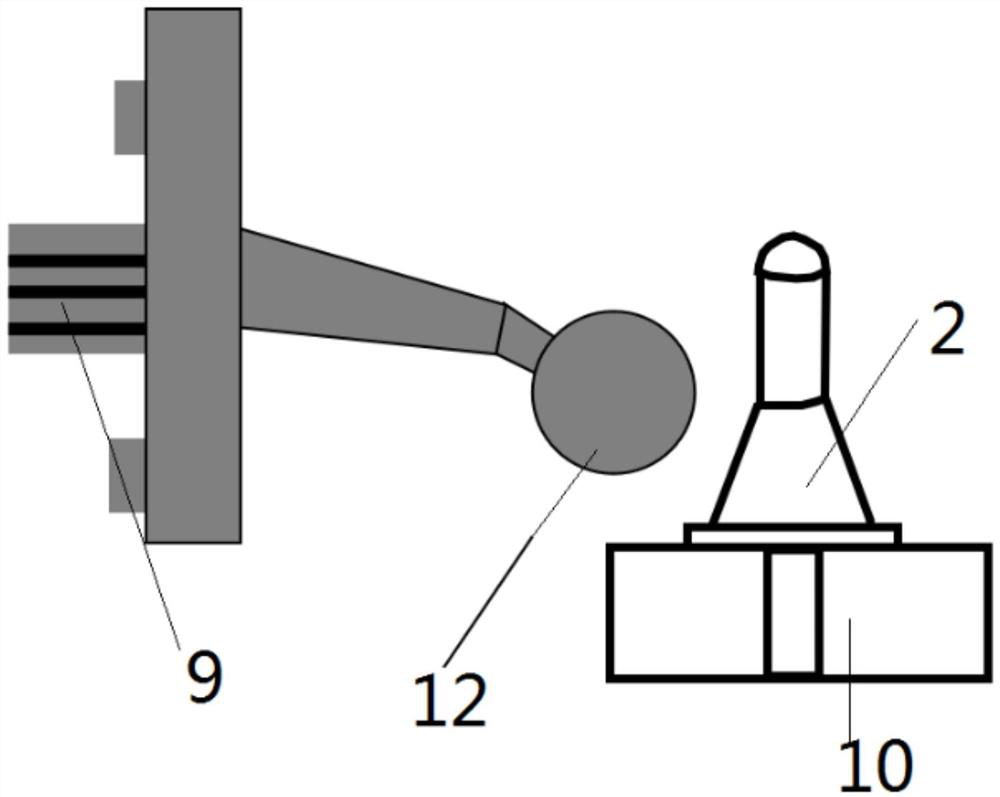

[0029] The reference signs in the drawings of the specification include: battery pack 1, punch 2, collision device 3, lifting platform 4, ground 5, limit plate 6, slide bar 7, acceleration sensor 8, buffer 9, slide block 10. Housing 11 , anti-backlash elastic block 12 , driven gear 13 , driving gear 14 , torsion spring 15 , rotating shaft 16 , and fixing piece 17 .

[0030] The embodiment is basically as attached Figure 1-Figure 4 Shown: a test method for evaluating the impact resistance of the bottom of the battery pack, including the following steps:

[0031] A. Pretreatment of battery pack 1: measure the voltage and insulation resistance of battery pack 1, the insulation resistance value is ≥100Ω / V, adjust the SOC state of the battery through the charging device; the state of charge of battery pack 1 is in the range of 0%-100% internal adjustment.

[0032] B. Test sample prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com