An electronically controlled crash testing machine

A collision test and electronic control technology, applied in the field of mechanical engineering, can solve problems such as inconsistent collision effects, difficult operation, scientific requirements of the test and difficulty in adapting to the requirements, and achieve the effect of improving the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

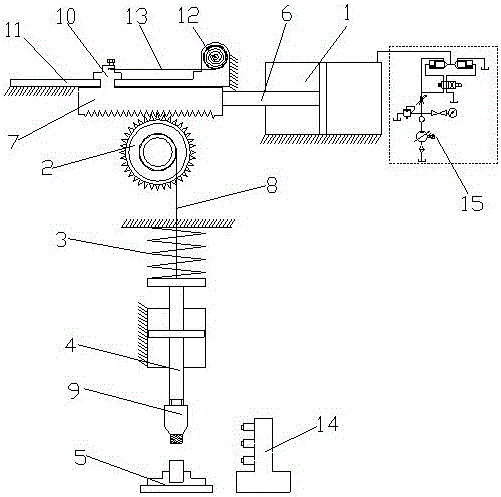

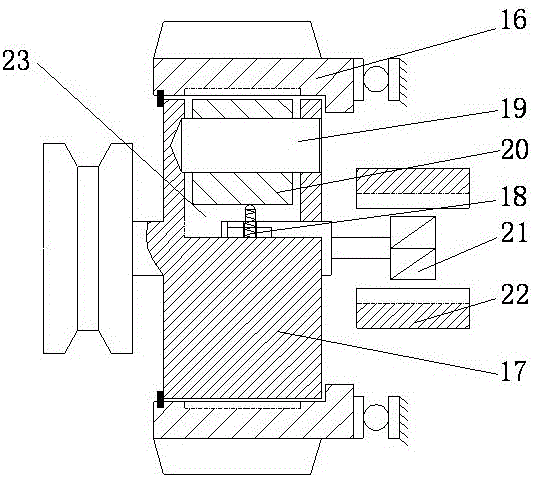

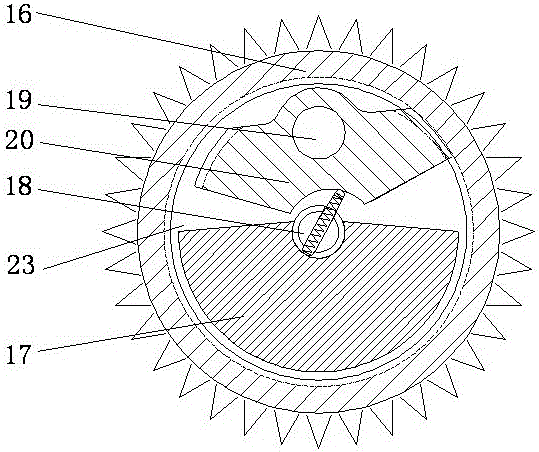

[0016] The present invention will be described below with reference to the accompanying drawings.

[0017] as attached Figure 1-4 Shown is an electronically controlled crash testing machine according to the present invention, including a plunger cylinder 1, a gear 2, a force storage spring 3, a push rod 4 and a workbench 5; the piston rod 6 of the plunger cylinder 1 is horizontal A rack 7 is connected, the rack 7 is arranged above the gear 2 and meshes with the gear 2, and the gear 2 is driven to rotate by the movement of the rack 7; the gear 2 includes a gear housing 16 and a runner 17; the runner 17 It is arranged in the gear housing 16 and can rotate in the gear housing 16; the runner 17 is provided with a groove 23; the groove 23 is provided with an internal gear block 20 connected by a pin 19; The bottom of the inner gear block 20 is arranged in an arc shape; the central axis of the runner 17 is provided with a spring rod 18; one end of the spring rod 18 extends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com