Overhead line phase sequence plate hot-line assembly and disassembly method and assembling device

An overhead line and installer technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as power outages, threats to the safe operation of lines, and easy rusting and disconnection, so as to reduce the number of line power outages, ensure power supply reliability, and facilitate The effect of live installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further described through embodiments with reference to the accompanying drawings.

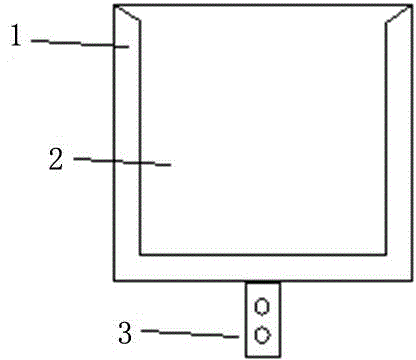

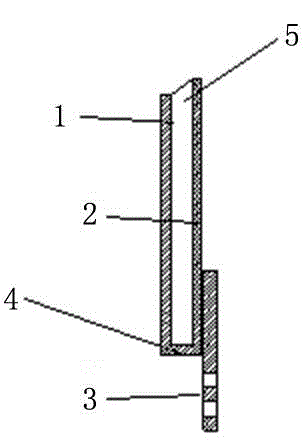

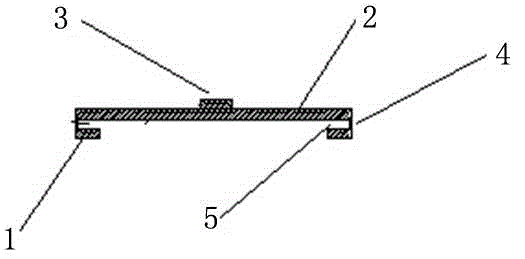

[0020] An overhead line phase sequence card live installer, comprising side baffles 1, a main substrate 2 and a connector 3. The main substrate is a square insulating plate, and side baffles are provided on the three edges of the front of the main substrate. The side baffle is U-shaped as a whole, with the U-shaped opening upward; the side baffle is also an insulating plate, and the side baffle is bonded to the main substrate through the vertical plate 4. There is a gap between the side baffle and the main substrate. The thickness of the gap is the height of the vertical board. The side baffle plate, the main substrate and the vertical board form a slot 5; the back of the main substrate is provided with a connector.

[0021] The main substrate is slightly larger than the phase sequence card, the back of the phase sequence card is glued with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com