Friction self-locking type prefabricated section spliced pier connecting device

A connecting device and friction self-locking technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of weakening the self-resetting performance of segmental assembled bridge piers, increasing the residual displacement of energy-consuming steel bars, and poor energy-dissipating performance of connections. Achieve stable and reliable energy consumption performance, strong energy consumption performance, and convenient on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

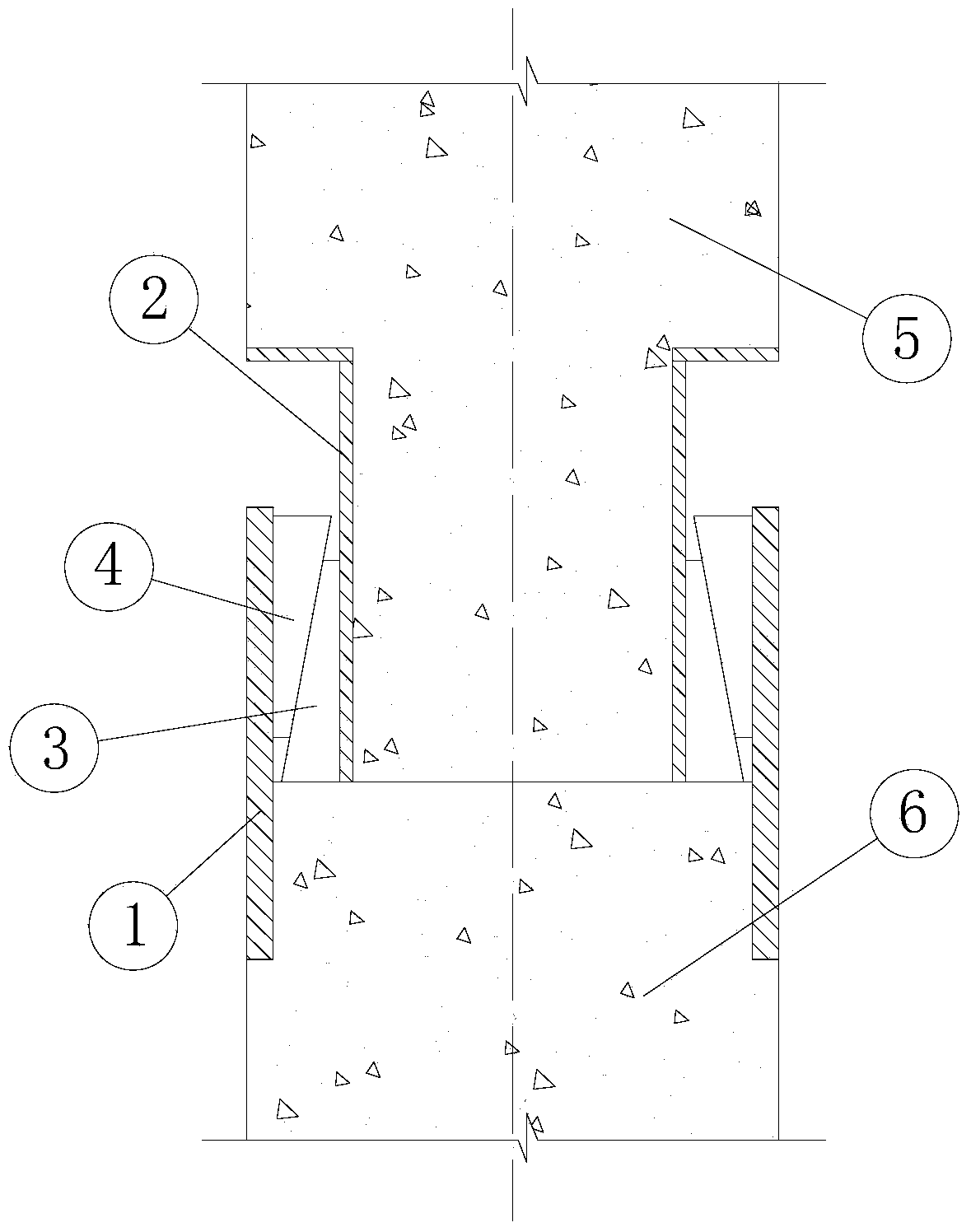

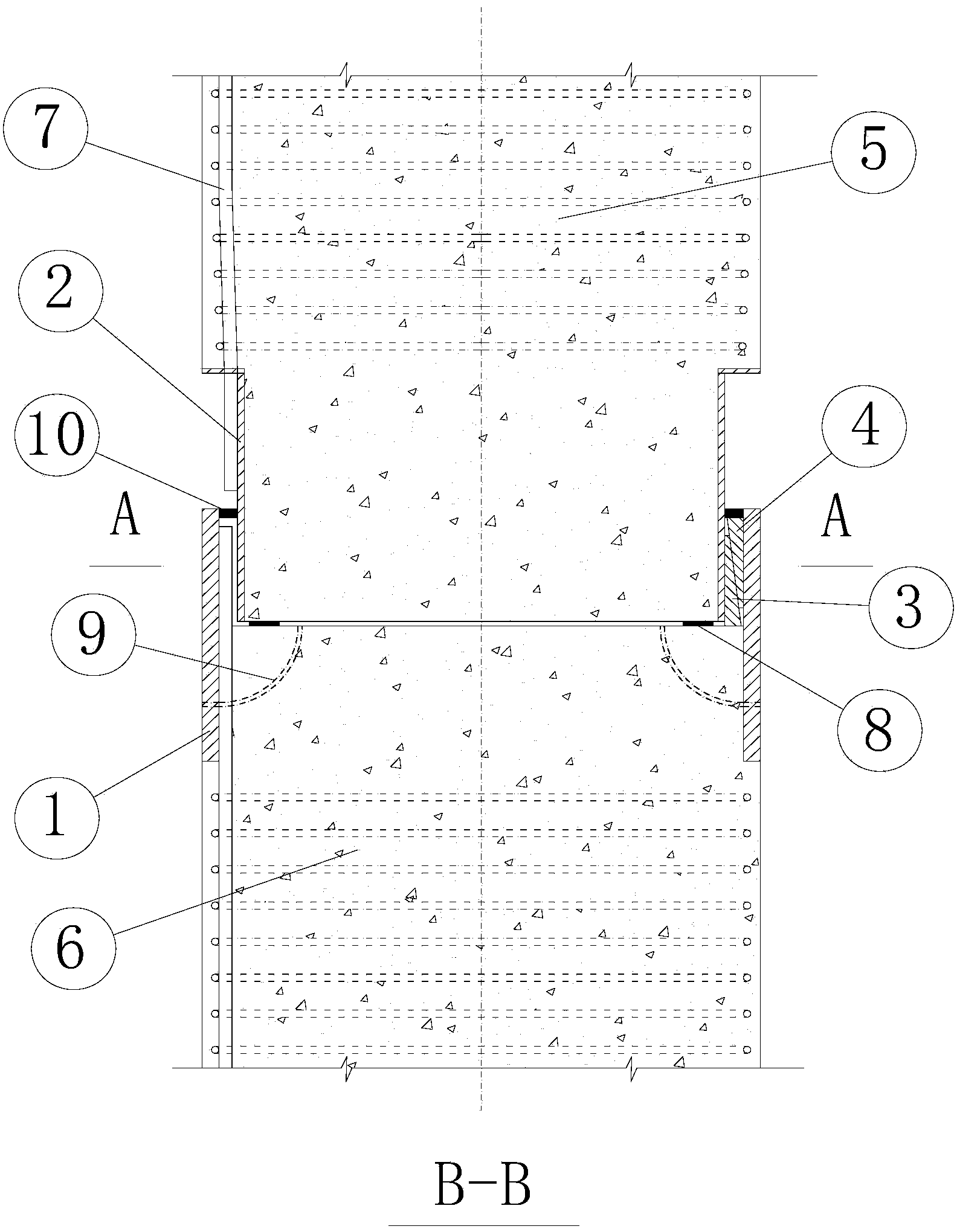

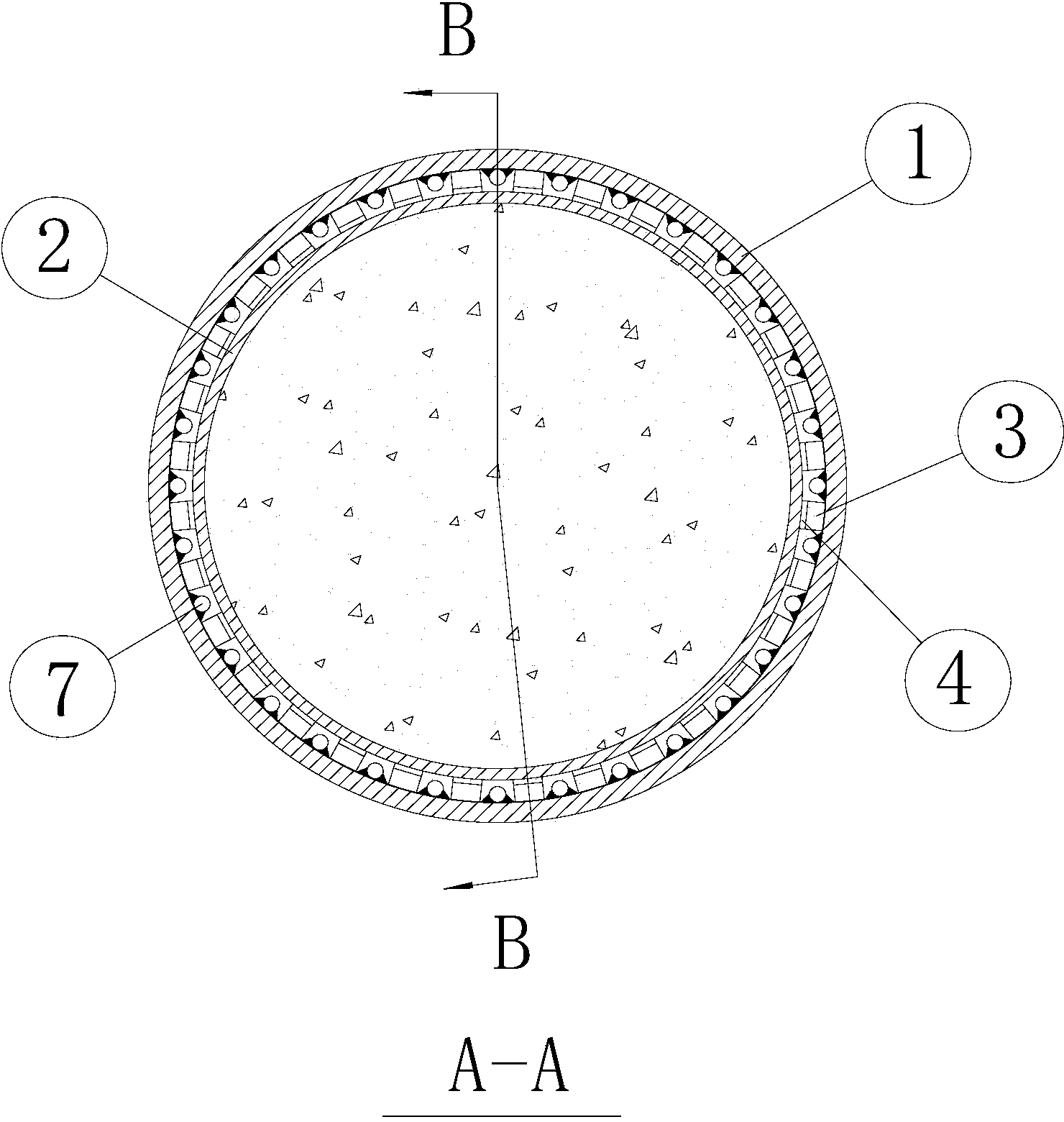

[0019] Below in conjunction with example for further detailed description. Specific examples such as figure 2 , image 3 shown. The figure includes an outer casing, an inner casing, an inner self-locking pin, an outer self-locking pin, an upper prefabricated segment, a lower prefabricated segment, longitudinal ribs, a rubber backing ring, a grouting pipe, and a sealing ring. For the convenience of describing the assembly process, the prefabricated segment above the connection being assembled is called the upper prefabricated segment, and the prefabricated segment located below the connection being assembled is called the lower prefabricated segment.

[0020] The concrete prefabricated segments are of circular cross-section. The inner casing and the outer casing are large-diameter steel pipes. When pouring the concrete upper prefabricated segment, the inner casing is pre-embedded at the lower end of the upper precast segment. The outer casing is pre-embedded at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com