Thin film sensor array and its preparation method

A thin-film sensor and array technology, which is applied in the field of thin-film sensor arrays and its preparation, can solve the problems of micron sensor elements failing to realize quantitative monitoring of structural fatigue cracks, and achieve excellent damage consistency, no need for signal conversion, and a wide monitoring range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

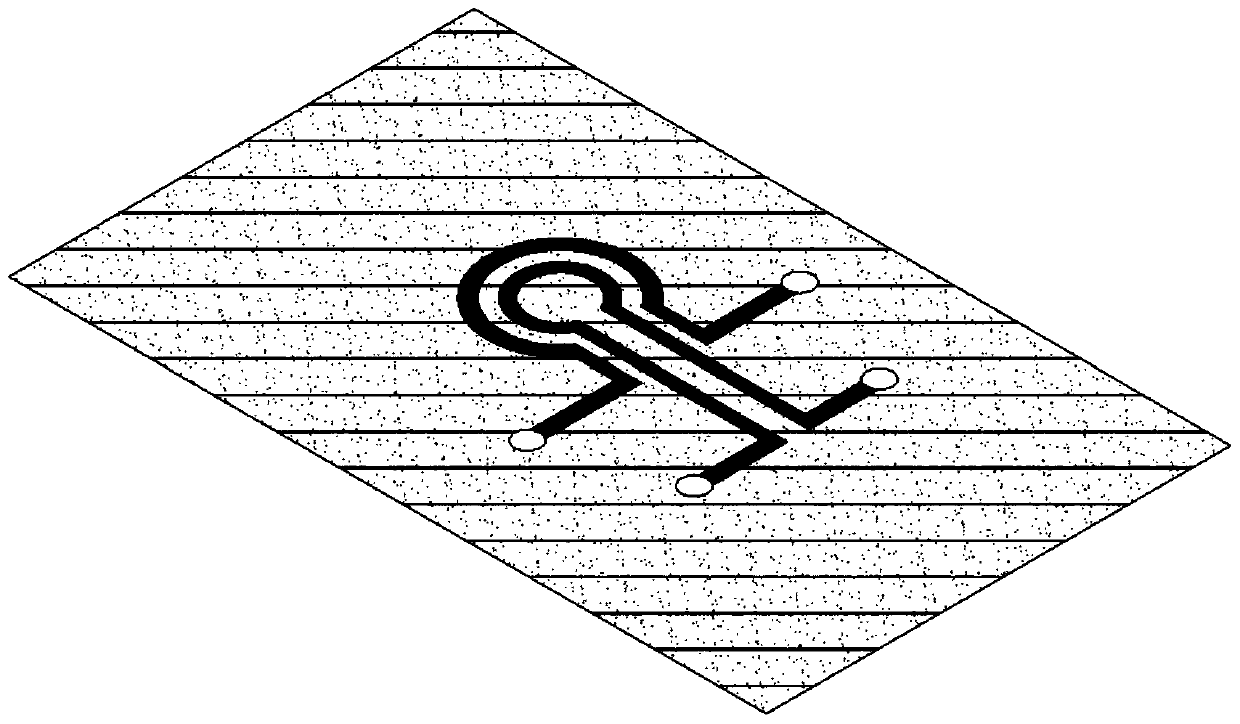

[0040] refer to figure 1 , the film sensor array of the present invention is composed of several concentric annular film sensors, lead points are also formed on the film sensors, and the arrangement of the lead points is based on the principle of convenient wiring. The composed thin film sensor array covers the whole monitoring area (that is, the metal structure fatigue dangerous part).

[0041] The composition of the annular thin film sensor is described below.

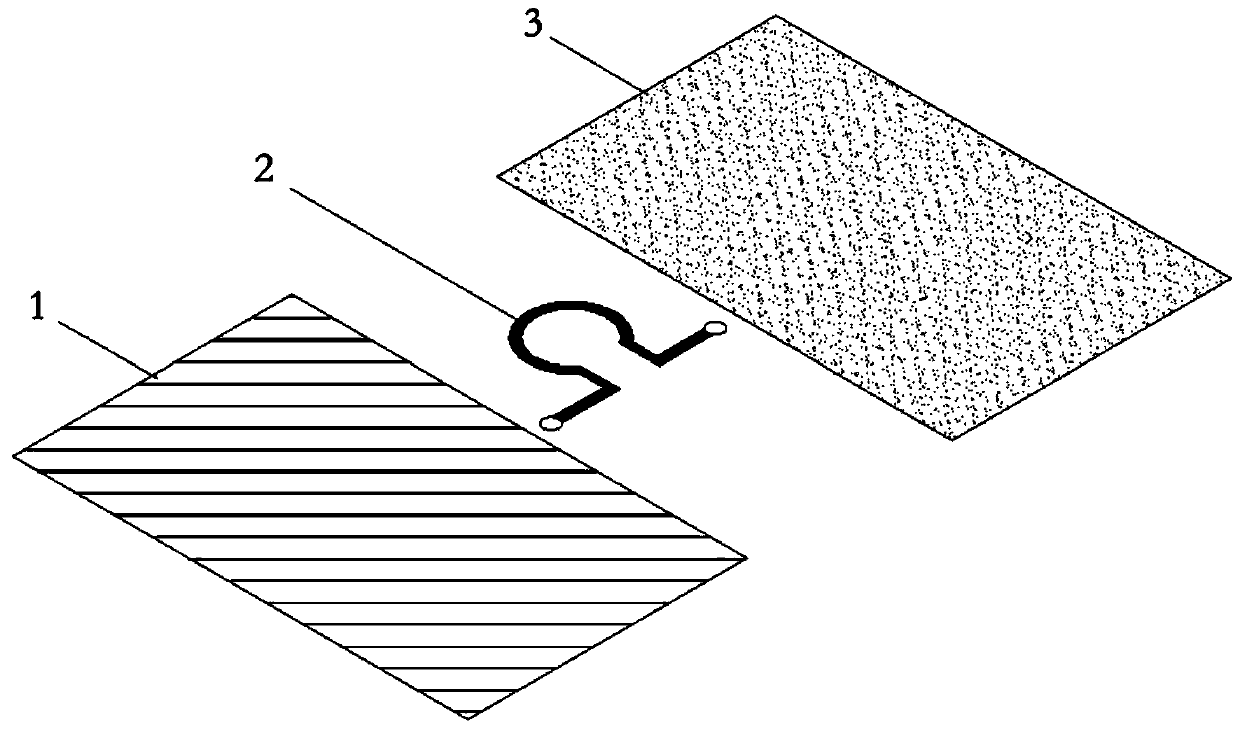

[0042] refer to figure 2 , the annular thin film sensor mainly includes a three-layer structure, from bottom to top: an insulating support layer 1 made of an insulating support material, a conductive sensing layer 2 made of a conductive sensing material, and an encapsulation protection material Prepared encapsulation protection layer 3, insulating support layer 1 is preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com