Smart phone test equipment and test method thereof

A technology for testing equipment and smart phones, applied in branch equipment, telephone communications, electrical components, etc., can solve the problems of inability to meet large-scale automated production, increase the number of mobile phone processes to be tested, and increase the area of the equipment, and achieve use adjustment. Convenience, simple structure and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

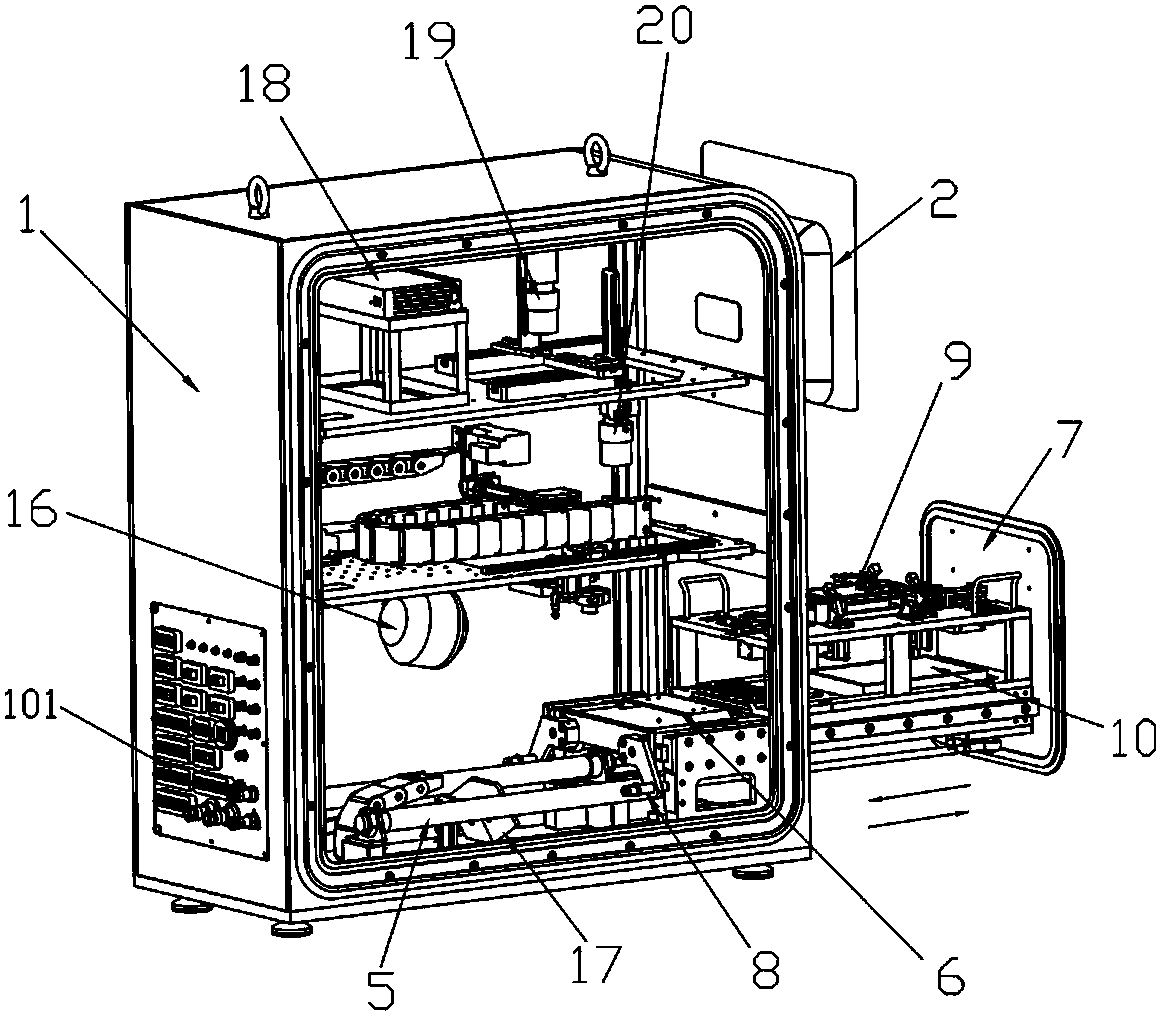

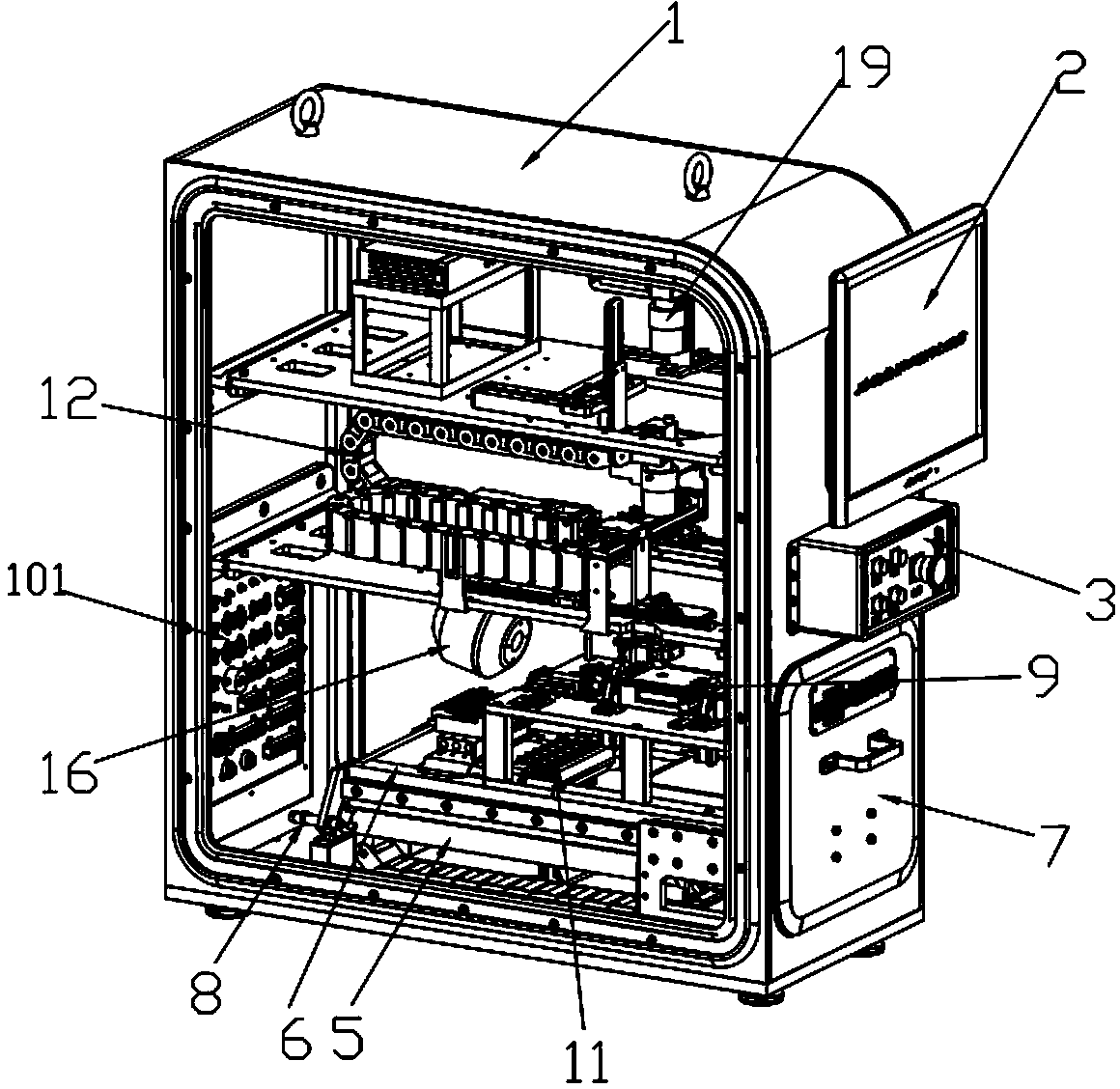

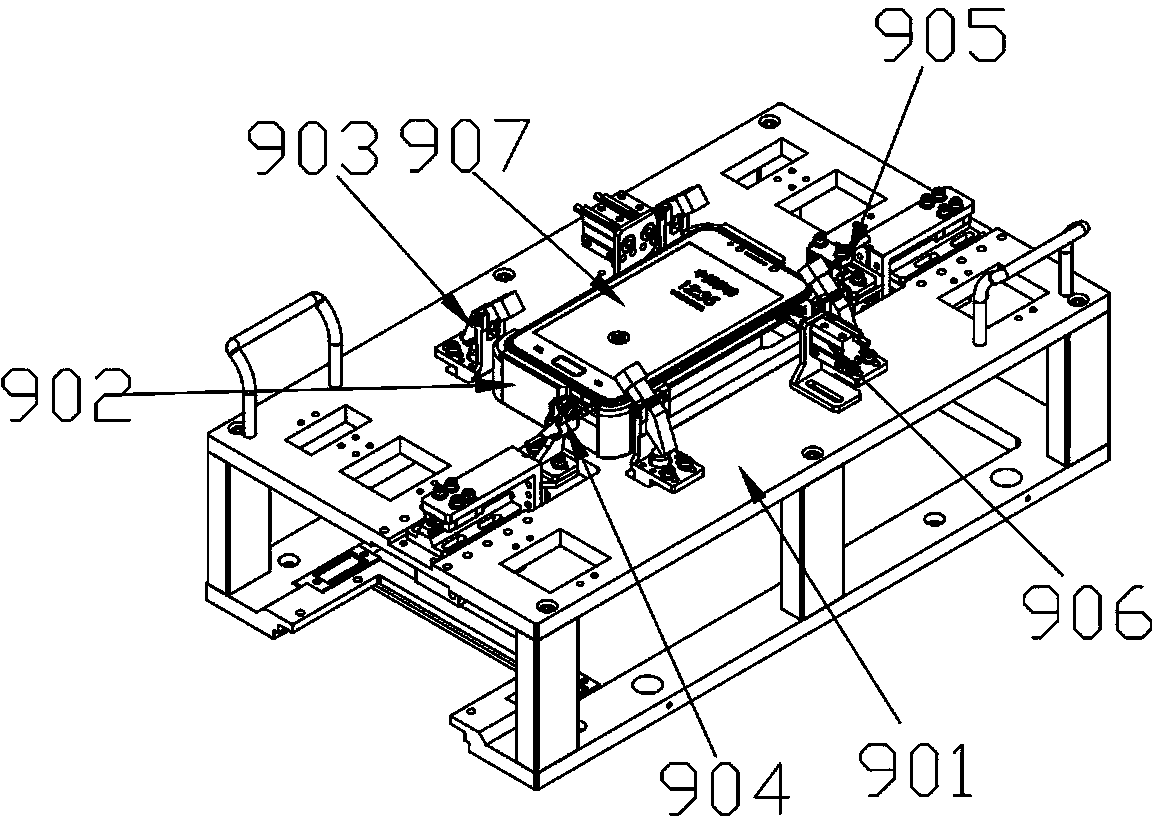

[0063] In this embodiment, for smart phone test equipment, please refer to Figure 1 to Figure 9 , which includes a protective box 1, a main test product mechanism, a simulated artificial mechanism, a visual camera mechanism, a display mechanism 2 and a control mechanism 3.

[0064] Wherein, the left and right sides of the protective box 1 are respectively provided with a left opening and a right opening, and a detachable left door and a right door are respectively sealed on the left opening and the right opening, and a communication interface is provided on the rear side thereof Group 4, the inner wall of the protective box 1 is provided with an electromagnetic shielding layer and a sound insulation layer, so that a sealed chamber that can prevent interference is formed inside the protective box 1 . The edges of the left ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com