Automatic walnut dehydrator

A dehydrator, walnut technology, applied in dryers, progressive dryers, food processing, etc., can solve the problems of unsuitable walnut dehydration, and achieve the effects of avoiding skin redness, reducing drying time, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

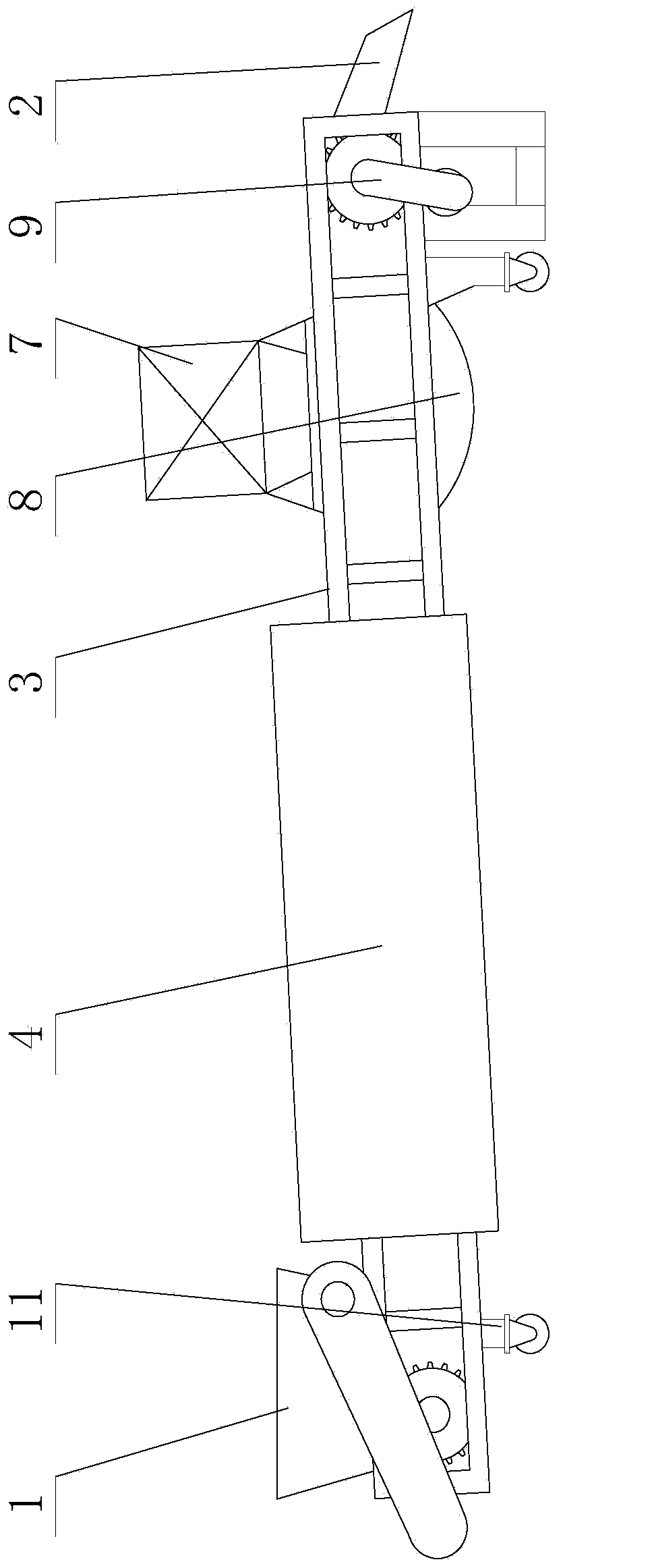

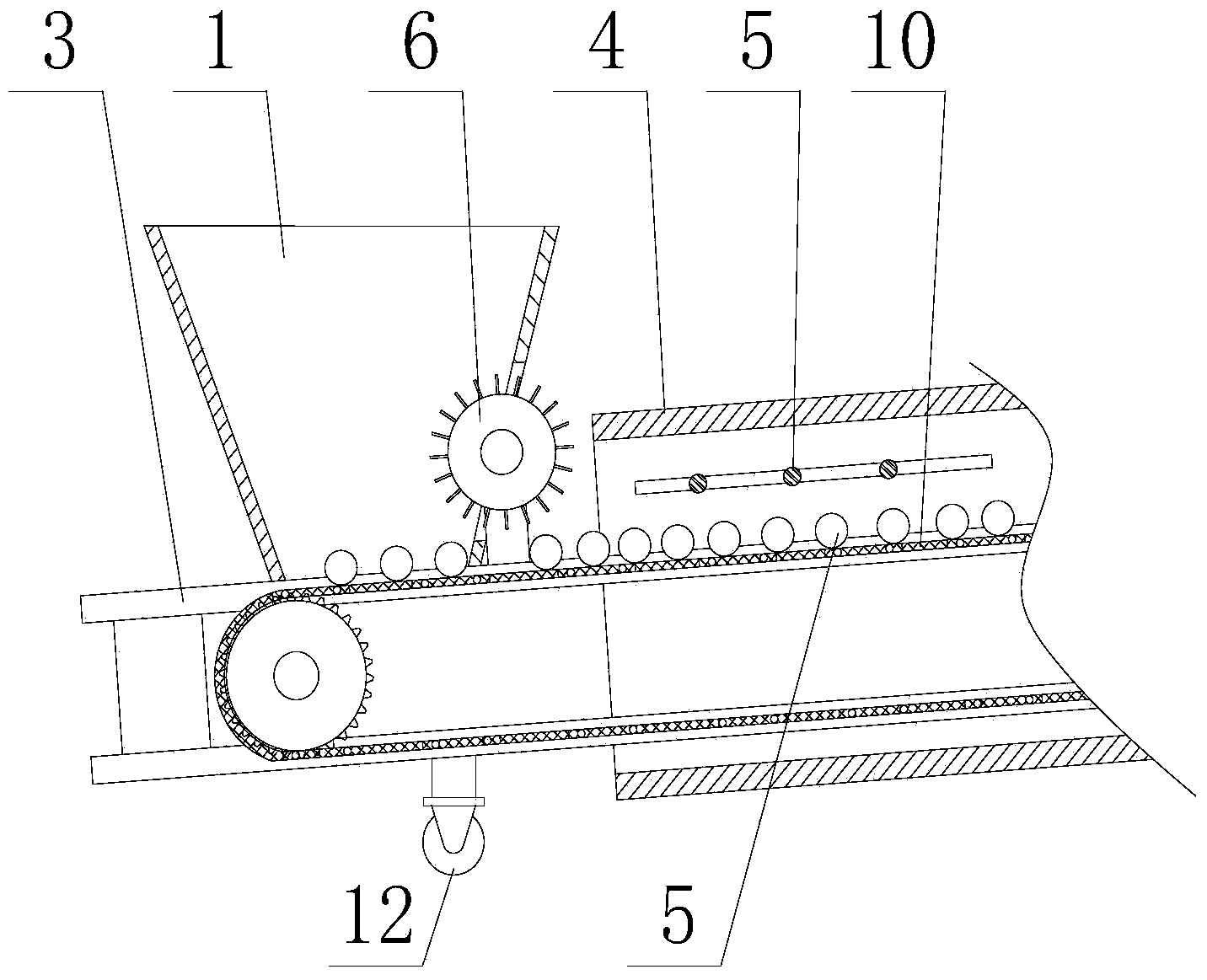

[0020] An automatic dehydrator for walnuts, comprising a bracket 3 with an inlet hopper 1 and an outlet hopper 2 respectively at both ends, a conveying mechanism for sending walnuts from the inlet hopper 1 to the outlet hopper 2 is arranged in the bracket 3, above the conveying mechanism, There is a drying chamber 4 between the hopper 1 and the hopper 2, and 5 sets of electric heating tubes are installed on the top plate of the drying room 4, and the 5 sets of electric heating tubes are connected to the electric control unit arranged on the bracket 3. The key is : Between the front end side wall of the feeding hopper 1 along the conveying direction and the conveying mechanism, there is a roller brush 6 that smoothes the walnuts to form a single-layer structure. The structure of the roller brush 6 includes a roller and nylon hairs arranged on the roller Brush, rolling brush 6 is driven by drive motor. Roller brushes with nylon brushes are added. When the conveying mechanism is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com