Vacuum chuck and bracket type vacuum adsorption equipment provided with vacuum chuck

A technology of vacuum adsorption and vacuum suction cups, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problem of damage to the surface of the material, achieve the effect of increasing friction and avoiding scratches on the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

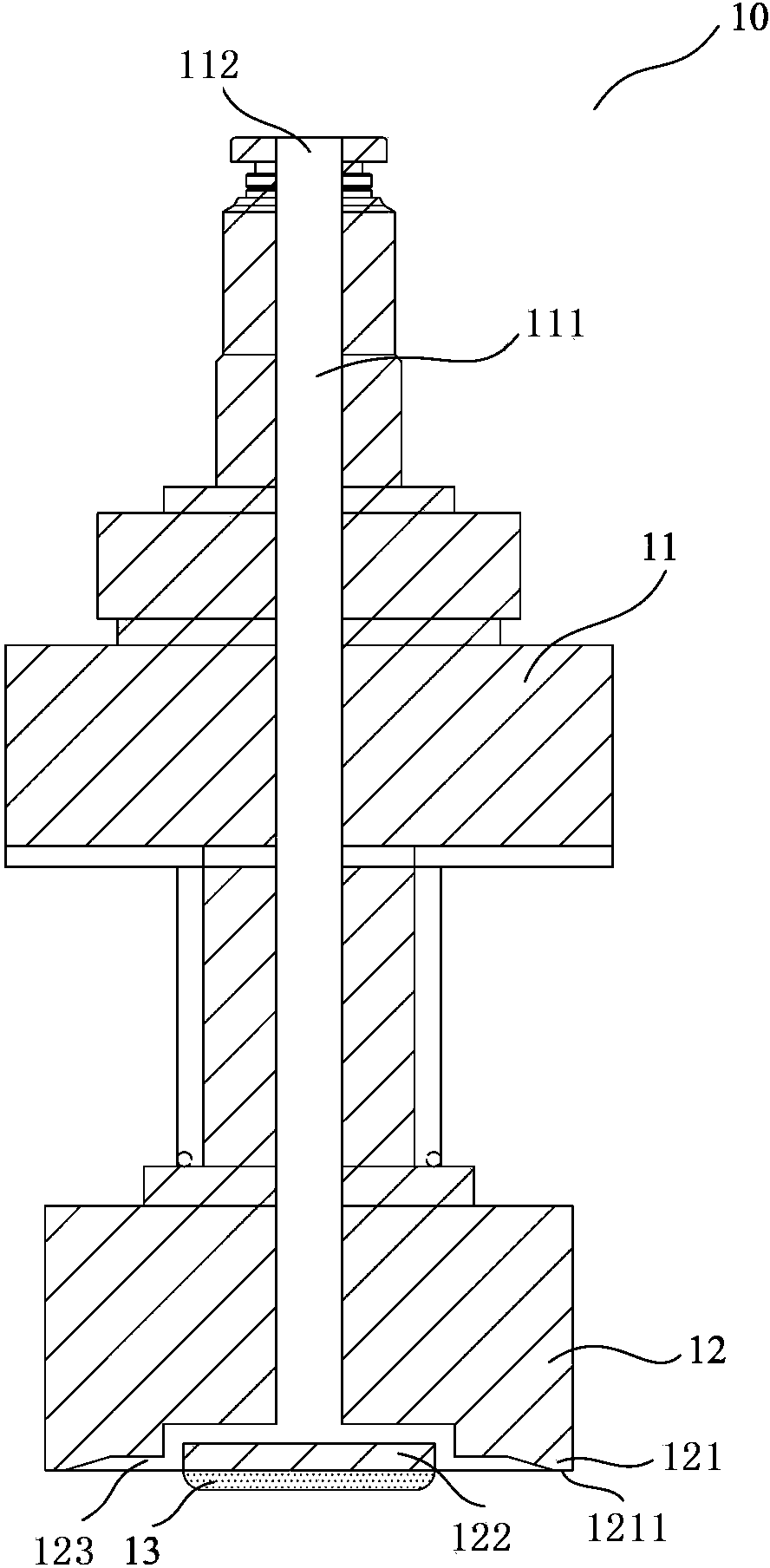

[0037] The structural features and operation modes of the present invention, together with illustrations, are described below for review reference. Furthermore, for the convenience of description, the proportions of the drawings in the present invention are not necessarily drawn according to the actual scale, but may be exaggerated. These drawings and their proportions are not intended to limit the scope of the present invention.

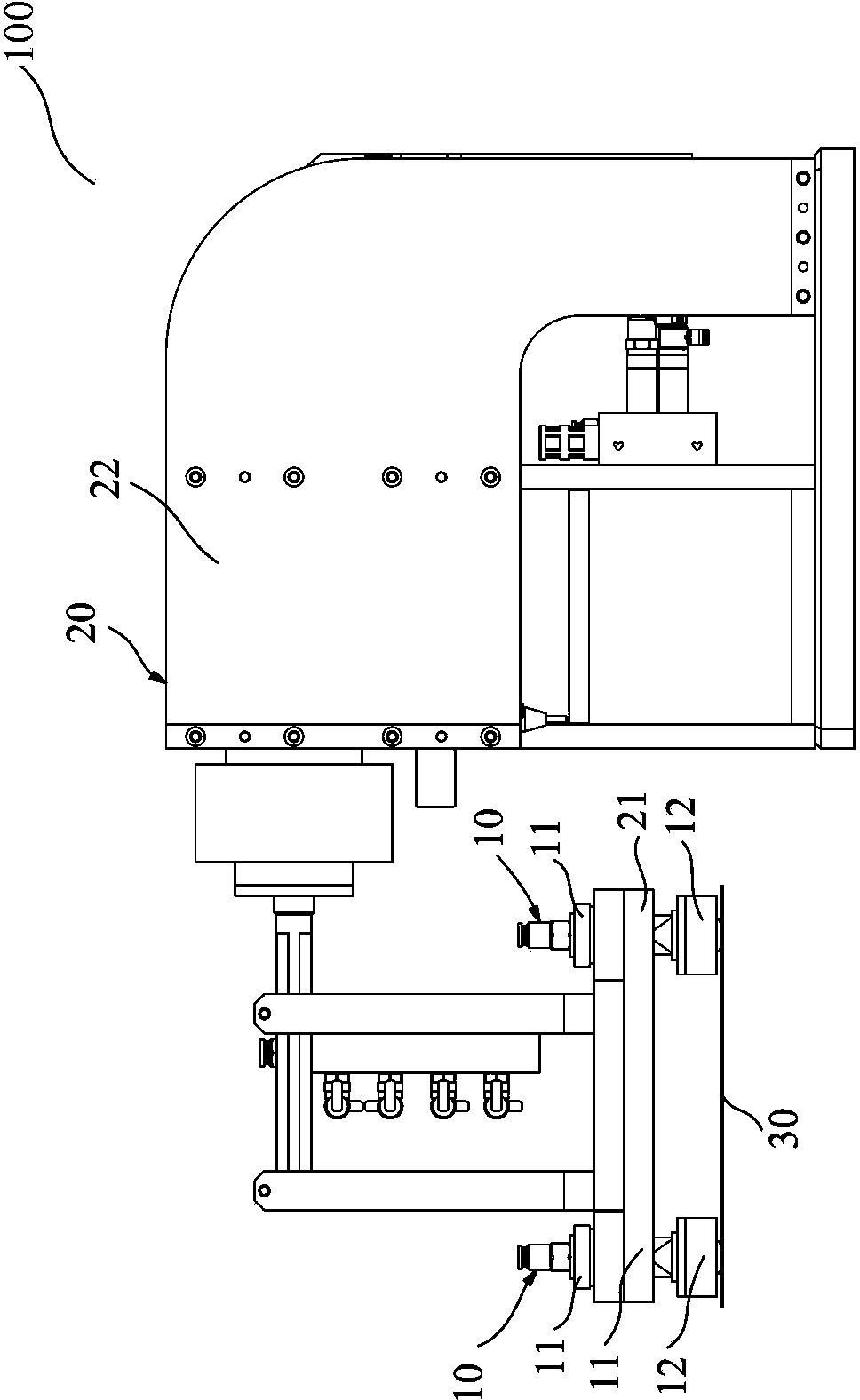

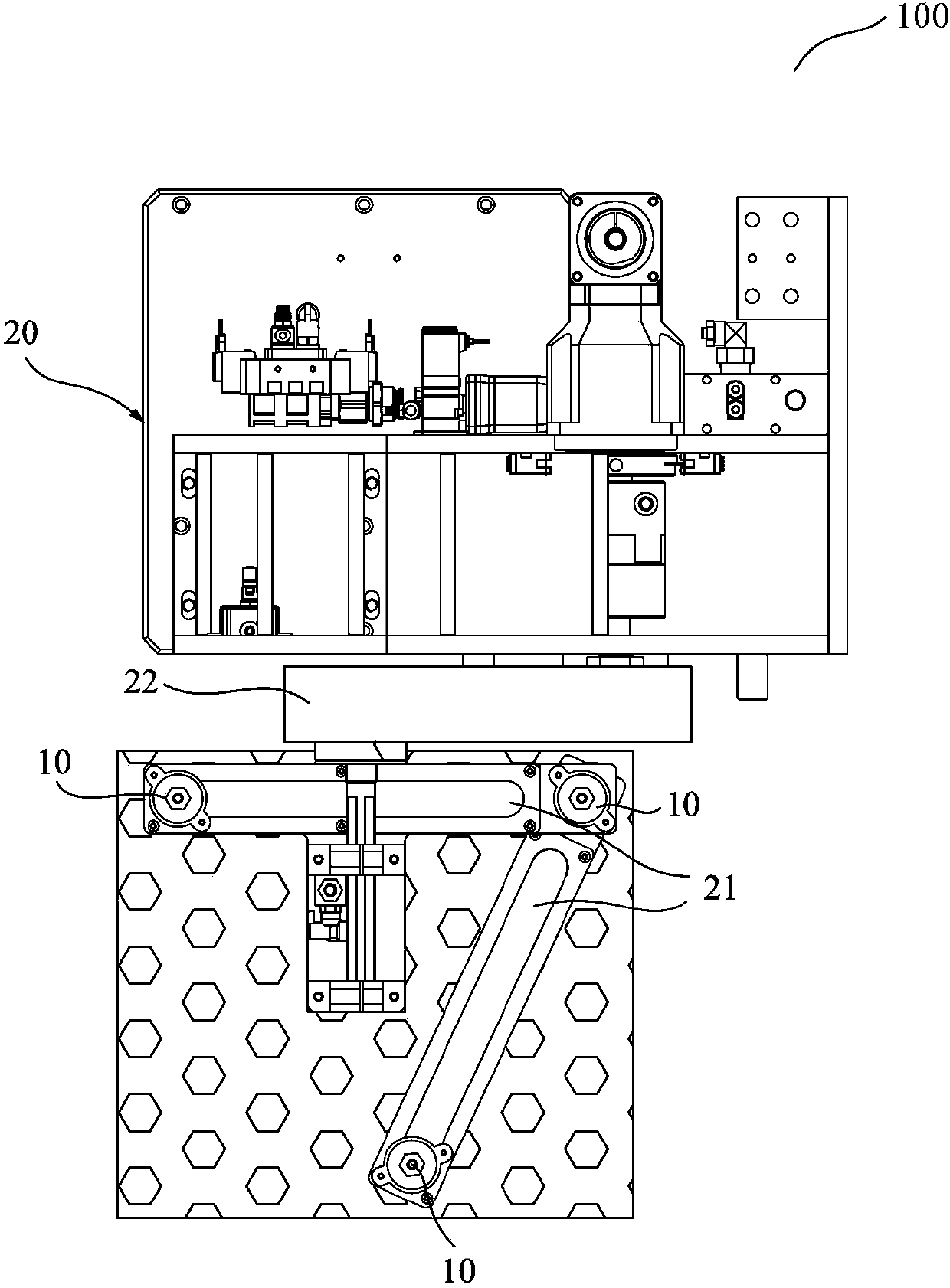

[0038] Please refer to the present invention figure 1 and figure 2 , is a schematic structural view of the bracket-type vacuum adsorption device of the present invention, as shown in the figure:

[0039] The present invention provides a stand-type vacuum adsorption device 100 , which mainly includes a moving device 20 and at least two vacuum suction cups 10 disposed on the moving device 20 . The moving device 20 includes at least one cross arm 21 and a carrier 22 connected to the cross arm 21 for operating the cross arm 21 to move. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com