Elastic label pushing device of labeling machine

A labeling machine and label pushing technology, which is applied to labeling machines, labels, packaging, etc., can solve the problems of slow label stripping speed, unsuitable for high-speed labeling, and large friction between label tapes, so as to reduce friction and strip labels The effect of better effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

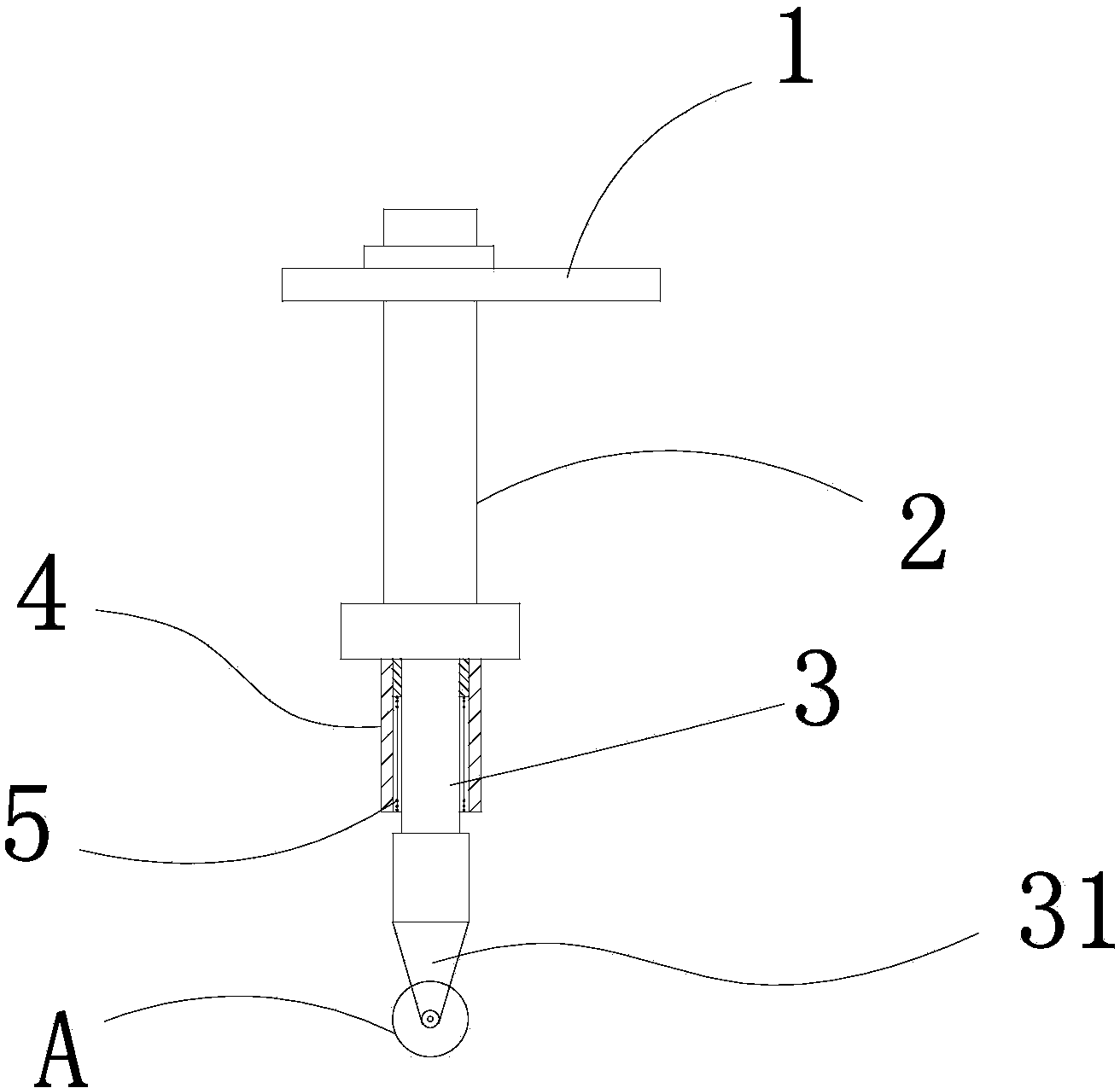

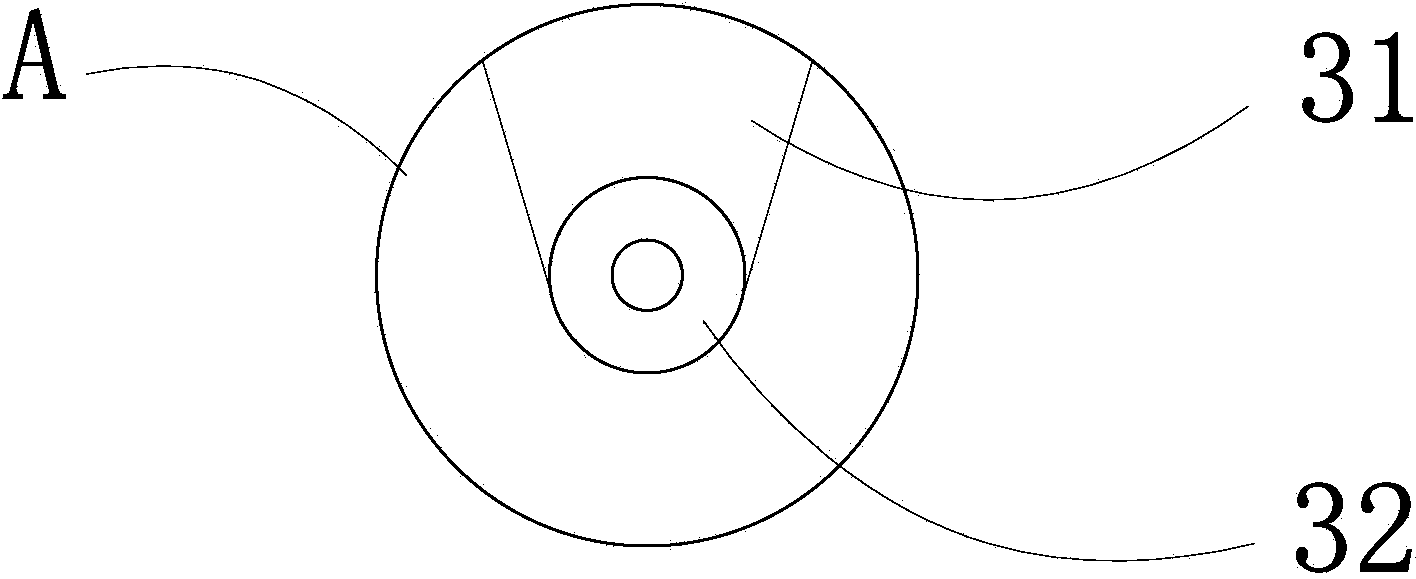

[0016] Such as figure 1 and figure 2 As shown, the elastic pushing device of the labeling machine of the present embodiment includes a pushing head 3 installed at the end of the piston rod of the cylinder 2, and the cylinder 2 is affixed to the frame by means of a bracket plate 1; The upper end is slidingly installed in the piston rod by the elastic sleeve 4, and the elastic sleeve 4 is equipped with a spring 5 that is placed on the upper end of the push head 3; the lower end of the push head 3 has a tapered push portion 31, and the tapered push portion The end device of 31 has guide roller 32.

[0017] In order to reduce the friction between the tape (not shown), the guide roller 32 is rotatably connected to the end of the tapered push part 31; for the convenience of replacing the push head 3, the push head 3 is screwed with the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com