Automatic wallboard installation device

A technology for automatic installation and wall paneling, which is applied in construction, building construction, and processing of building materials, etc., and can solve the problems of time-consuming, labor-intensive and low-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

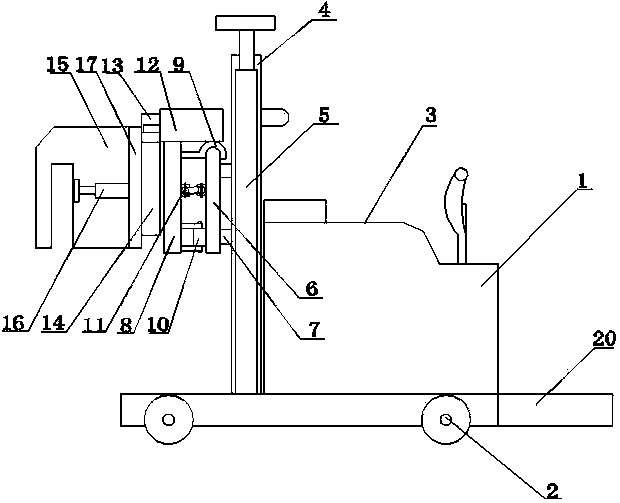

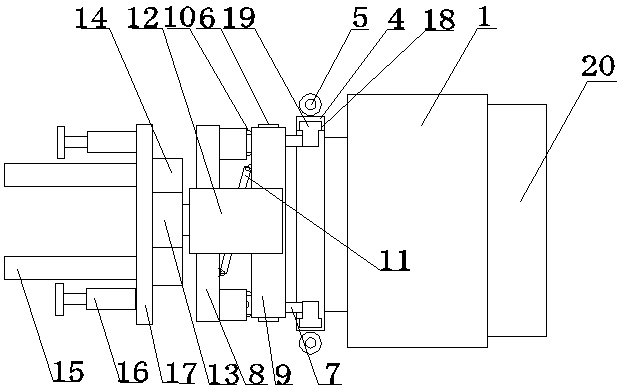

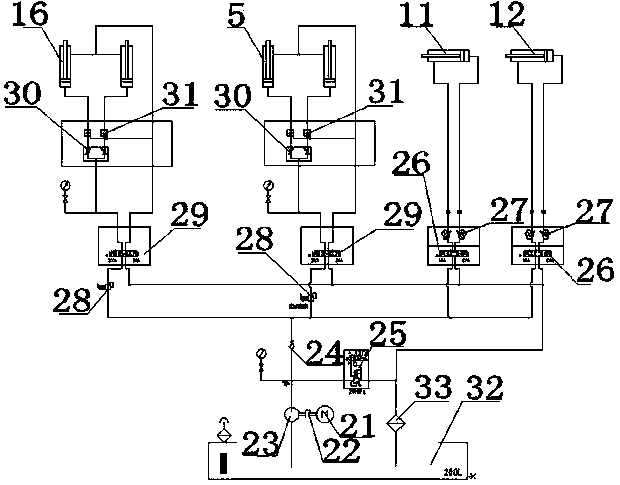

[0012] according to figure 1 , 2 , 3, the present invention relates to a wall panel automatic installation device, which includes a control box 1 with a walking wheel 2 at the bottom, a control platform 3 is provided on the upper surface of the control box 1, and a control platform 3 is provided on the control box 1. The rear end of the box body 1 is provided with a pedal platform 20, and the front end of the control box body 1 is fixedly equipped with a door-shaped frame body 4, and the inner sides of the columns on both sides of the door-shaped frame body 4 are respectively provided with slide rails 18, Each of said slide rails 18 is slidably matched with a slide block 19 respectively, and each of said slide blocks 19 is fixedly connected with a first connecting arm 7 respectively, and the other end of each said first connecting arm 7 is connected with a lifting panel 6 is fixedly connected, and the first oil cylinder 5 that drives the slider 19 up and down is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com