High voltage static discharging tube

A high-voltage electrostatic and discharge tube technology, applied in electrostatic and electromagnetic control tubes, single discharge channel tubes, magnetrons, etc., can solve the problem of difficulty in precise voltage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with implementation examples:

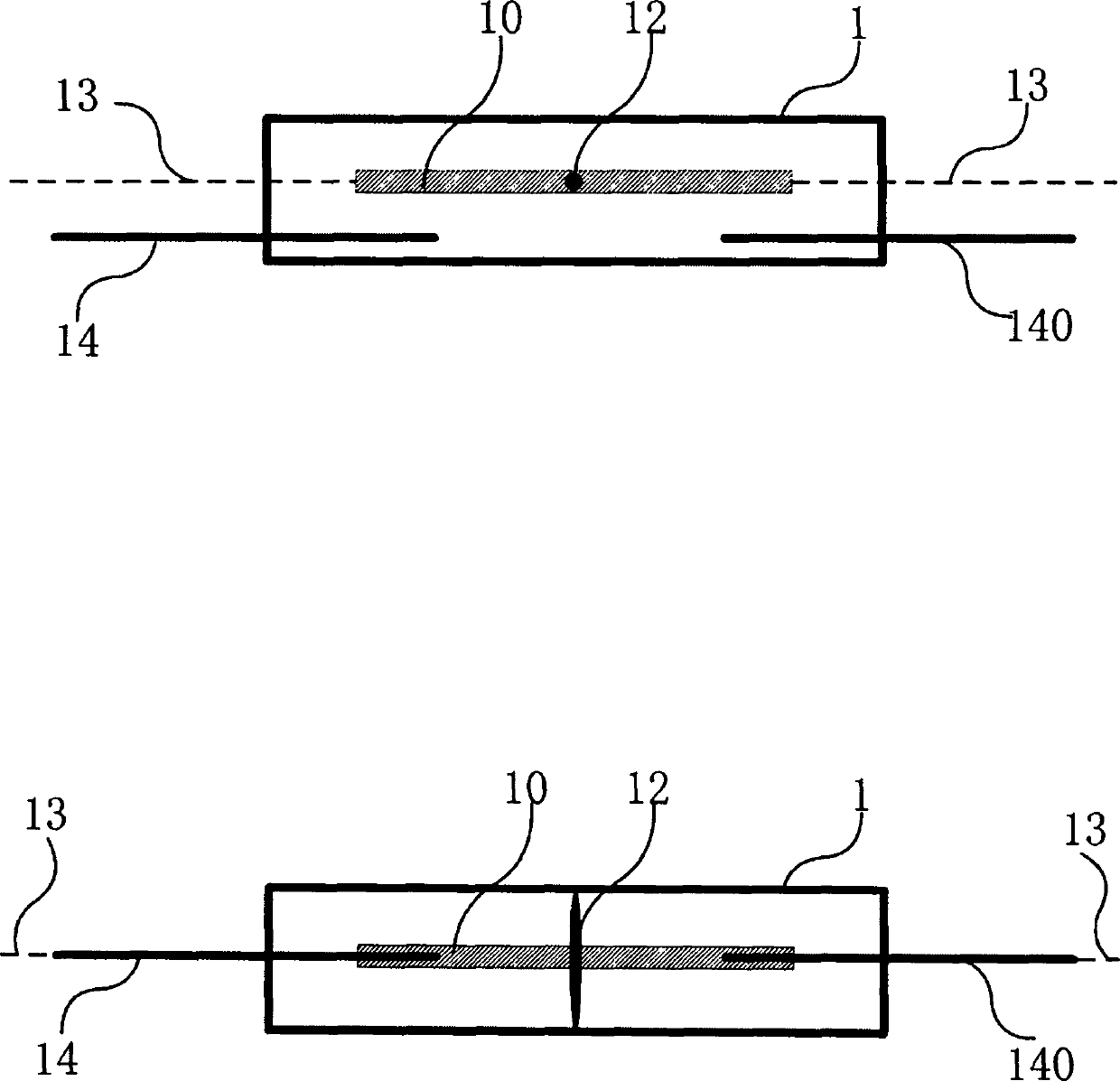

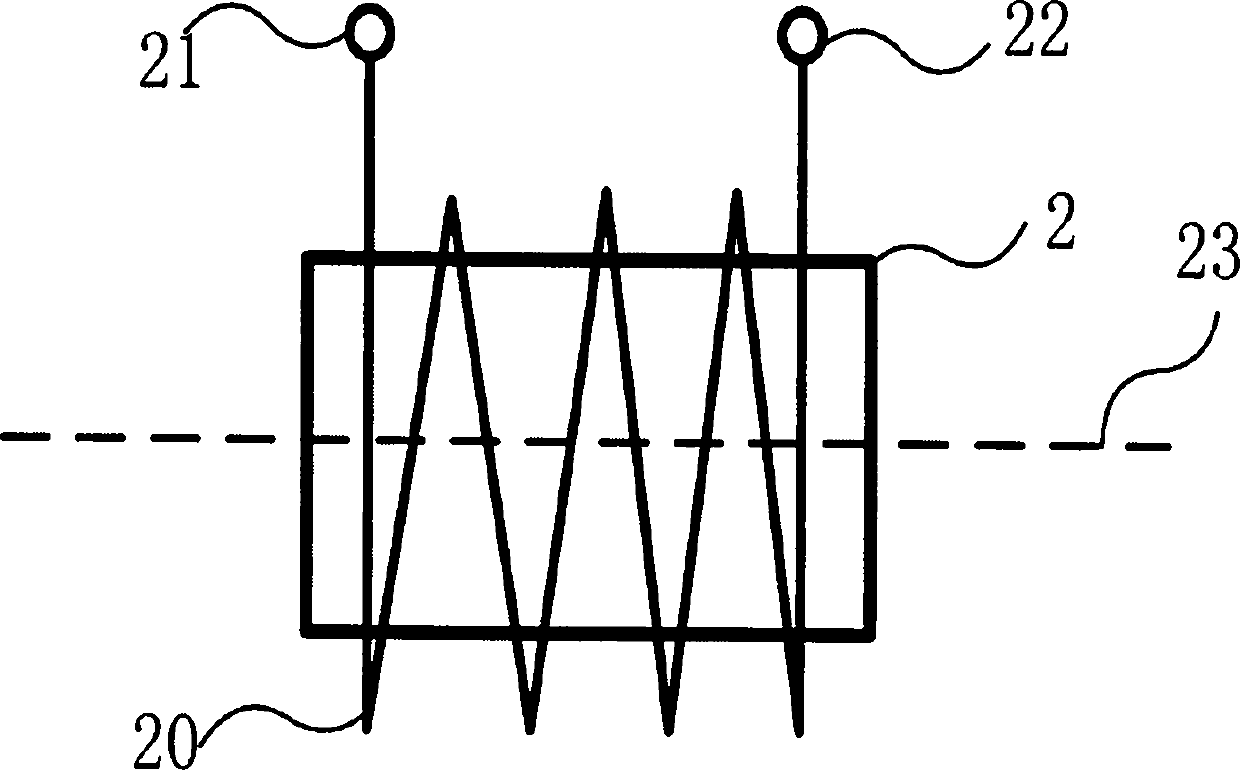

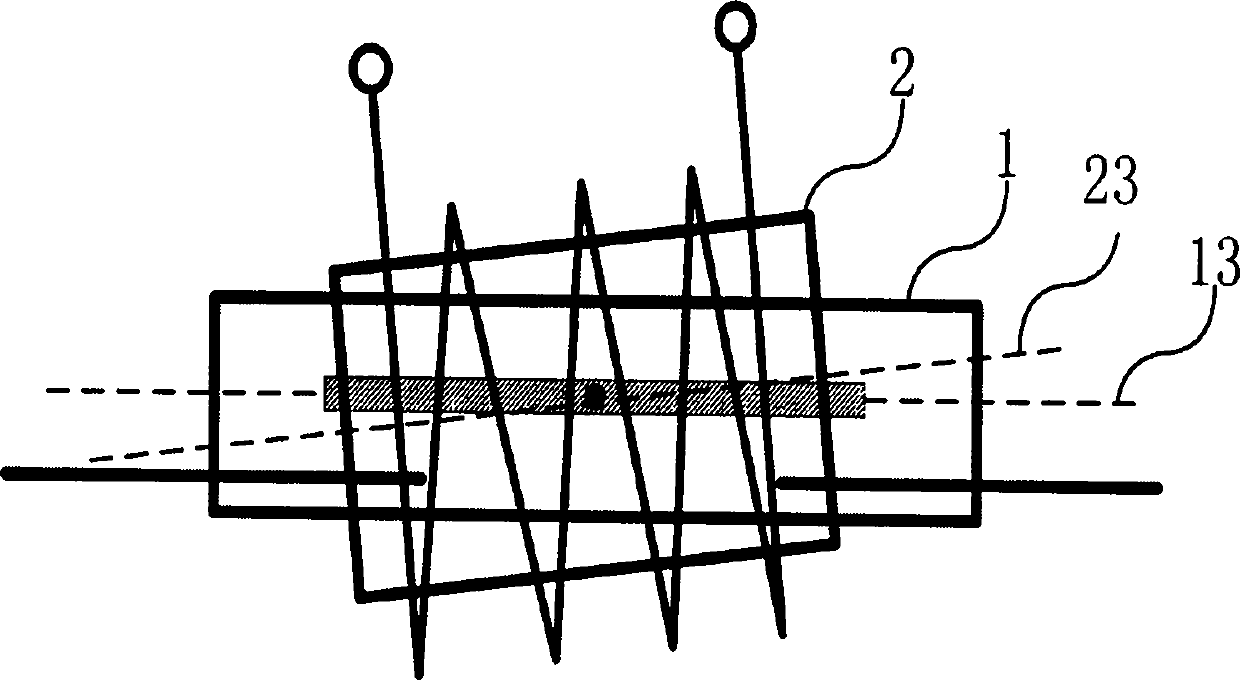

[0023] Such as figure 1 , figure 2 and image 3 As shown, this implementation example is made up of a vacuum glass tube 1, a conductive and magnetic torsion beam 10, a solenoid 2, and two main conductors 14, 140; the conductive and magnetic torsion beam 10 is an equal-arm lever; Located inside the vacuum glass tube 1, the torsion shaft 12 of the conductive and magnetic torsion beam 10 forms a rotational connection with the vacuum glass tube 1, and the axis of the torsion shaft 12 is perpendicular to the axis 13 of the vacuum glass tube 1: the solenoid 2 is set in the vacuum glass tube 1 Externally, the solenoid 2 covers the conductive and magnetic torsion beam 10, the axis 23 of the solenoid 2 is coplanar with the axis of the torsion shaft 12 of the conductive and magnetic torsion beam 10, and the axis 23 of the solenoid 2 is parallel to the vacuum glass tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com