Variable-speed shake mechanism

A variable and machine base technology, which is applied to mechanical equipment, transmission devices, components with teeth, etc., can solve the problems that the swing amplitude and swing speed cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

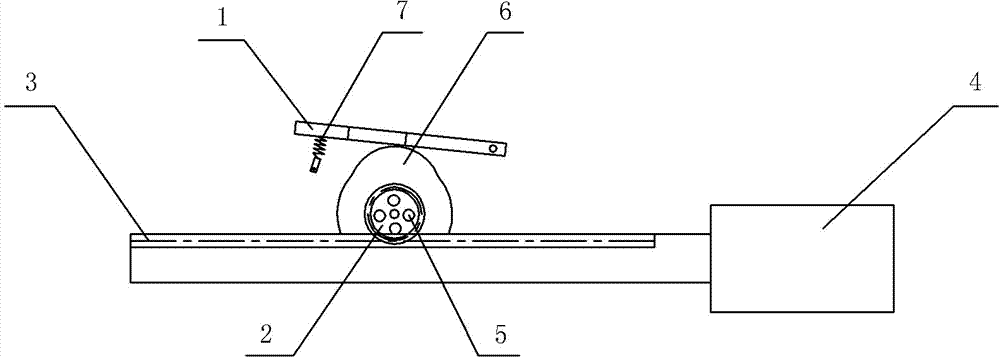

[0010] Such as figure 1 As shown, a variable-speed rocking mechanism in this embodiment includes a base, a swing rod 1, a gear 2 connected to the base, and a rack 3 slidingly connected to the base. The rack 3 is driven by a cylinder 4. , the gear 2 meshes with the rack 3, the gear 2 is provided with a weight-reducing hole 5, the gear 2 is coaxially connected with a cam 6, the cam 6 and the gear 2 are detachably connected, the cam 6 offsets the swing rod 1, and the swing rod 1 is The telescopic structure is provided with an angular velocity sensor, the right end of the swing rod 1 is hinged on the frame, and the left end is connected to the frame by a spring 7 .

[0011] When working, the cylinder 4 drives the rack 3 to move to the left, the driving gear 2 rotates clockwise, and the cam 6 also rotates clockwise. Cam 6 offsets. The cylinder 4 drives the rack 3 to move to the right, the driving gear 2 rotates counterclockwise, and the cam 6 also rotates counterclockwise. The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com