Thread clamping equipment having shockproof function, illumination function and capacity of regulating thread clamping range of thread clamping head and applied to hosiery production

A technology for adjusting clips and thread clamping, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of inconvenient use, unfavorable popularization and use, complicated mechanical thread clamping structure, etc., and achieves convenient use, simple structure, and labor reduction. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

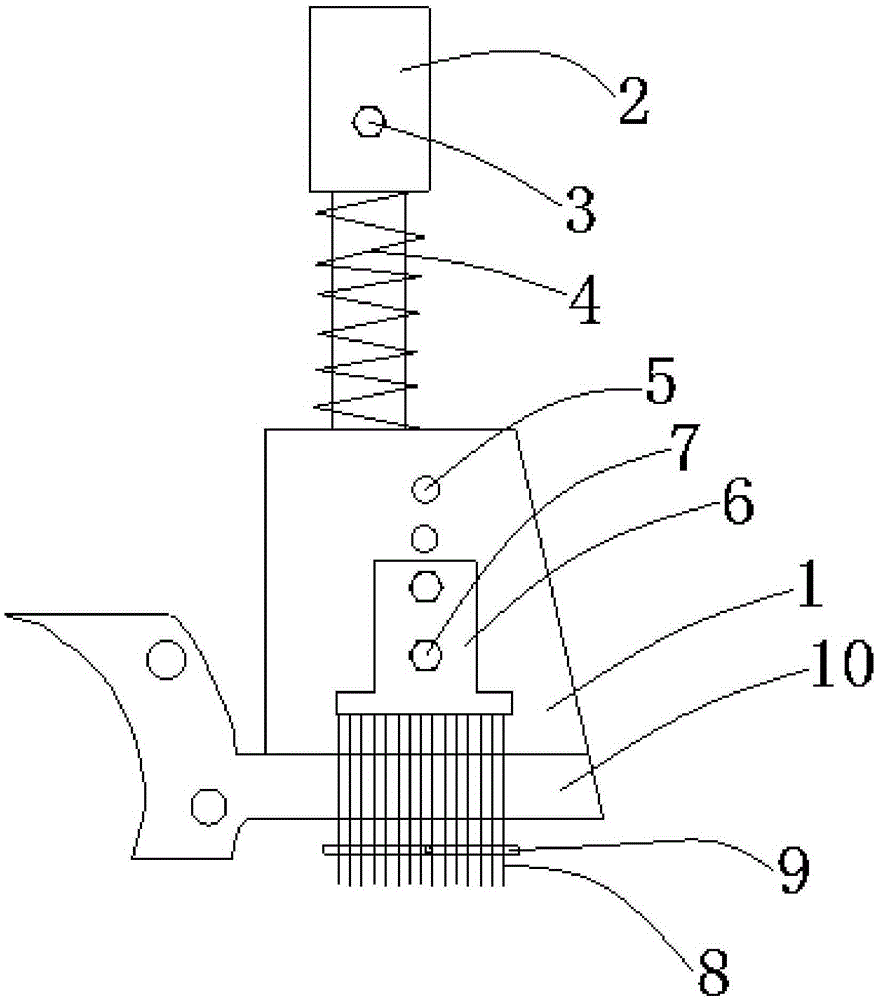

[0012] like figure 1 As shown, the thread clamping device for making socks of the present invention includes a brush holder 1, a fixed head 2, a clamping rod, a thread clamping head 10 and a brush seat 6; the brush holder 1 is provided with a plurality of threaded holes 5. One end of the brush holder 6 is connected to the brush holder 1 through the cooperation of the screw 7 and the threaded hole 5, and the other end is provided with a plurality of brushes 8; the fixed head 2 is connected to one end of the clamping rod, and the clamping The other end of the wire rod passes through the brush holder 1 and is connected to the clamping head 10; The thread clamping device for hosiery making of the present invention not only solves the problem of thread clamping for hosiery machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com