On-site wire connector

A technology for on-site production of wires and connectors, which is applied in the direction of clamping/spring connections, devices to prevent wrong connections, etc., can solve problems such as inapplicability, increased production costs of crimping screws, and increased difficulty in screw processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

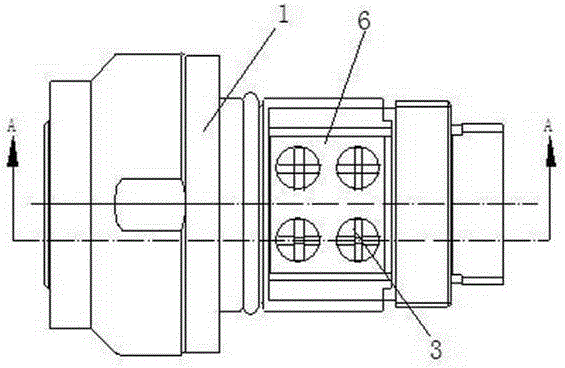

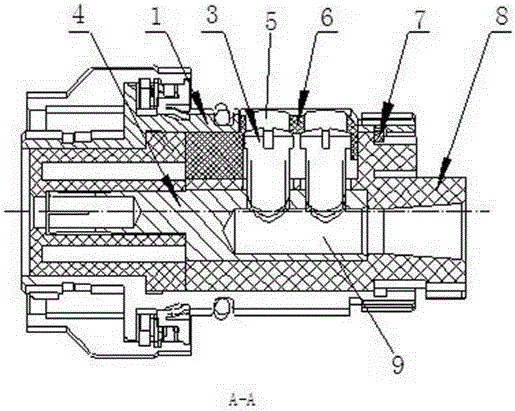

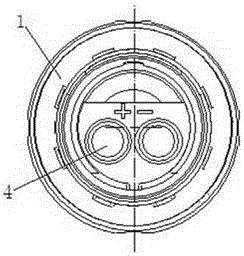

[0019] Examples of on-site wiring connectors Figure 1-7 As shown: it includes a metal shell 1 with a plug-in end at the front end. An axial mounting hole extending axially along the front and rear directions is arranged in the metal shell. An insulator 8 with a built-in contact 4 is installed in the axial mounting hole. On the contact A wire core perforation 9 for the corresponding cable core is provided, and a screw perforation 12 is arranged on the hole wall of the wire core perforation, and the screw perforation is equipped with a press for fixing the cable core to the corresponding wire core perforation. wire screw 3. The insulator is provided with a platform 11 connected to the outer peripheral surface of the insulator through a concave step, and an insulator perforation 13 corresponding to the screw perforation is provided on the platform, and a radial installation gap is formed between the table top of the platform and the wall of the axial installation hole , the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com