Electric insulator cleaning device

A technology for cleaning devices and insulators, which is applied in the field of power systems and achieves good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

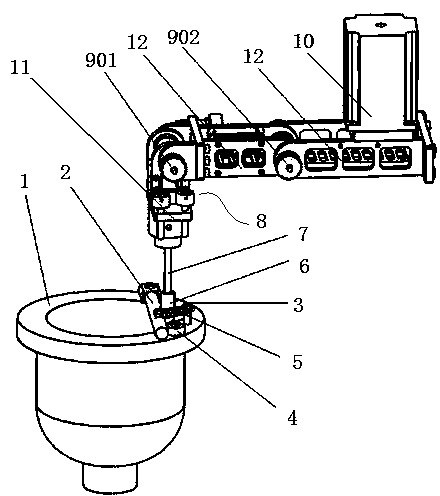

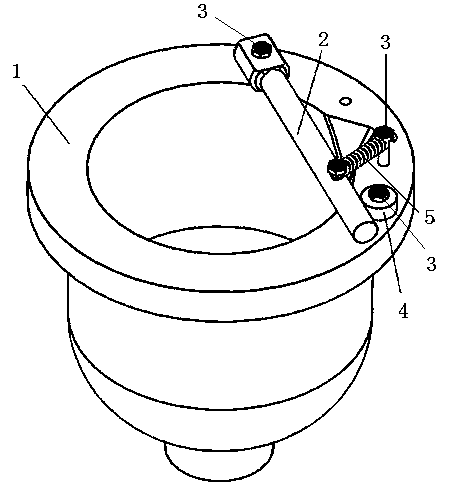

[0021] Such as figure 1 and figure 2 As shown, an insulator electric cleaning device includes a water tank 1, a connecting rod 2, a limit column 4, a tension spring 5, an electric cleaning head 6, a flexible shaft 7, an electric cleaning arm 8, a stepping motor 10, and a cleaning joint seat 11 Connect the joint seat 12 with the arm, the water tank 1 is used to collect the sewage when cleaning the insulator, and it is made of nylon plastic, which has good insulation and light weight. The sewage is used for the salt density detection of the insulator and for evaluating the regional environment The insulation performance of insulators in the medium and small power system and the safety performance of the power grid, and then scientifically guide and formulate the overhaul and maintenance plan of the power system. One end of the connecting rod 2 is fixed on the upper edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com