A cleaning device for pick-and-place head of a placement machine

A technology of cleaning device and pick-and-place head, which is applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc. Improve work efficiency, ensure normal operation, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

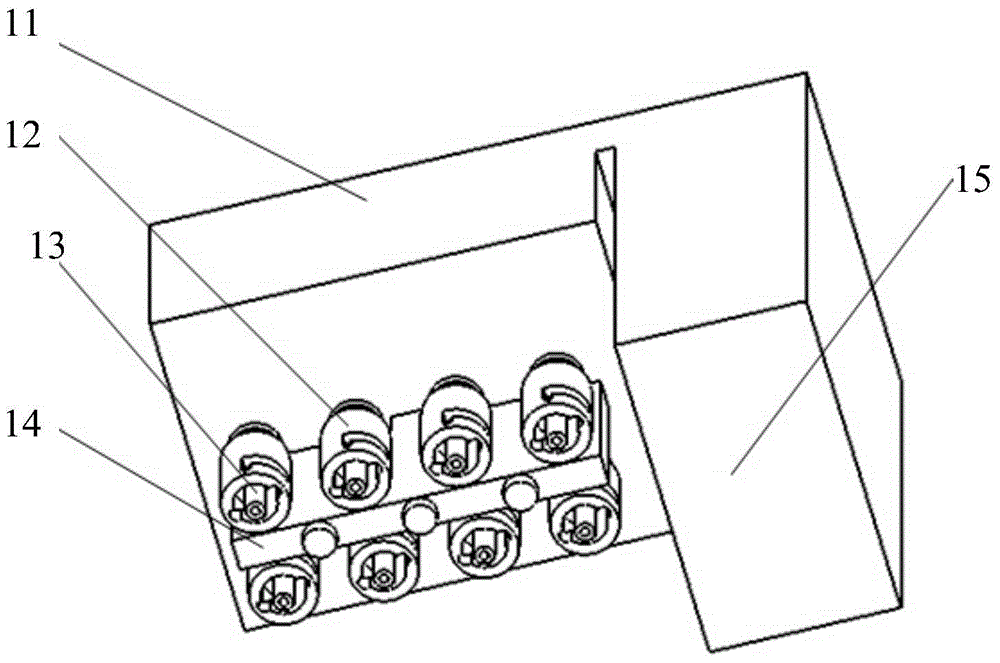

[0032] At present, most of the pick-up heads in the factory are cleaned manually. After removing the suction nozzle, use a special tool to manually put the dust-free paper that has absorbed the cleaning agent on the connecting head that is connected to the pick-up head and the suction nozzle, and manually rotate and clean the pick-up head. Set your head until you meet the requirements. The efficiency of this cleaning method is very low, and only one interface of the pick-up head can be cleaned at a time. The cleaning efficiency is low, and the labor load is large, which leads to long downtime of the production line and brings large downtime losses to the factory.

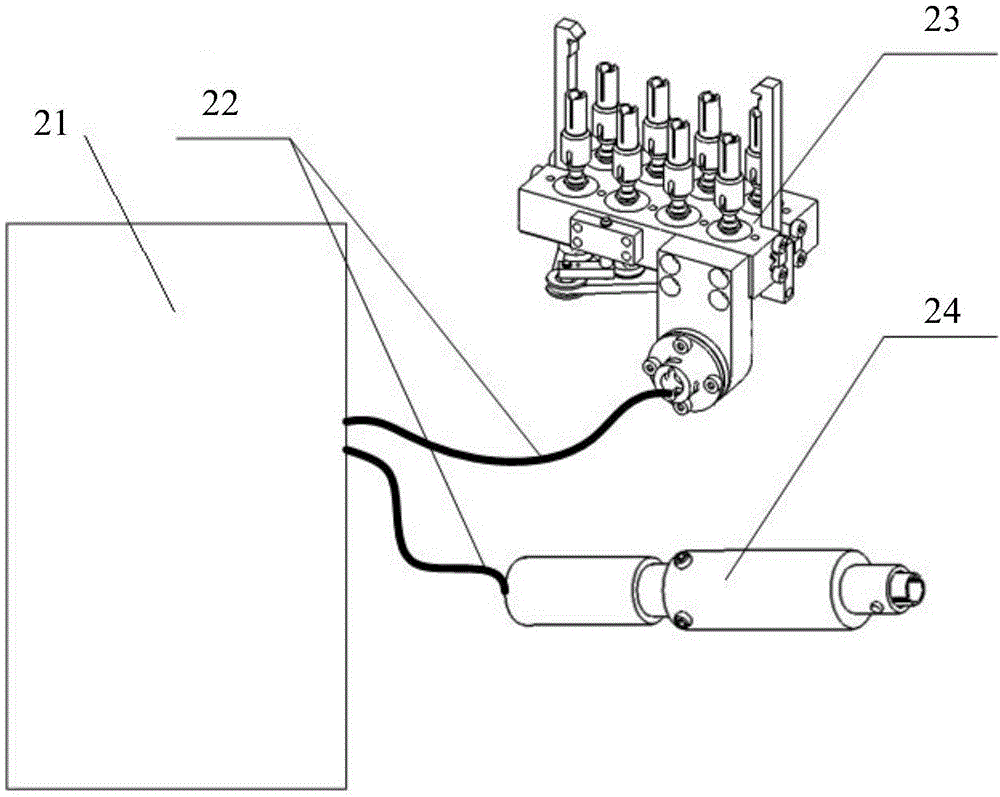

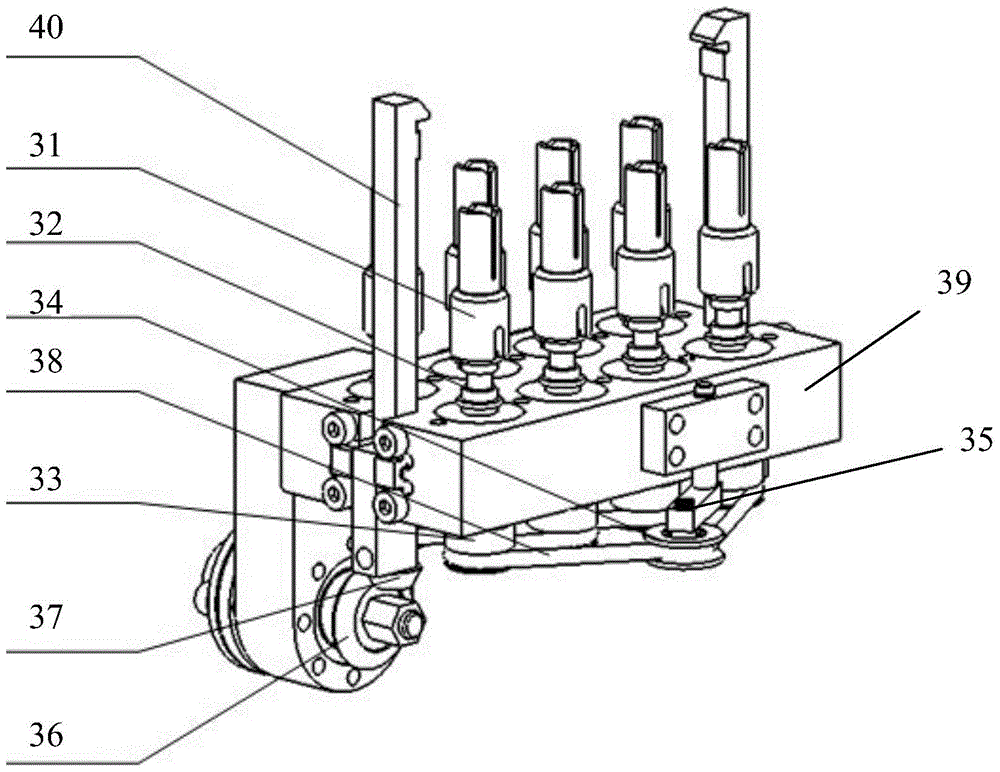

[0033] Aiming at the deficiencies in the prior art, the present invention provides a cleaning device for picking and placing the head of the chip mounter. When cleaning, by docking the cleaning head with the connecting head, the driving element drives the cleaning head to rotate and clean the outer circle of the conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap