Wrench for butterfly nut

A technology for wing nuts and wrenches, which is applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems that affect the normal operation of appliances and the locking force of wing nuts is not strong, so as to enhance the locking force and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

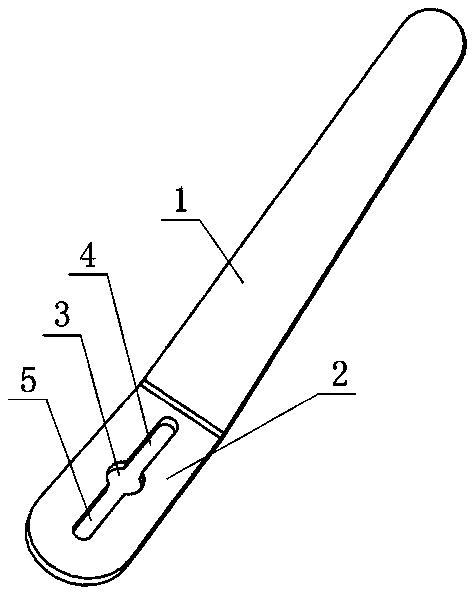

[0014] figure 1 Among them, a wing nut wrench includes a handle plate 1 and a seat plate 2, and the handle plate 1 is connected to the seat plate 2. The center of seat plate 2 is provided with the round hole 3 that matches with the round platform of wing nut, and the both sides of round hole 3 are respectively provided with the long slot hole one 4 and the slot two 5 that match with wing nut both sides ears. The length of the handle plate 1 is longer than that of the seat plate 2 . Both the handle plate 1 and the seat plate 2 can be made of stainless steel. In order to reduce the production cost, the handle plate 1 and the seat plate 2 are an integral structure. The length of the handle plate 1 may be 3 to 8 times the length of the seat plate 2 . The thickness of the handle board 1 and the seat board 2 may be 2-3 mm. An angle may be formed between the handle board 1 and the seat board 2 . The angle formed between the handle plate 1 and the seat plate 2 is 120°˜175°. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com