Method for preparing anti-crystallization rosin

An anti-crystallization and rosin technology, which is applied in the field of rosin deep processing, can solve the problems of difficult to achieve stable control, different degrees of crystallization, high difficulty coefficient, etc., and achieve the effect of preventing and delaying the crystallization of rosin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

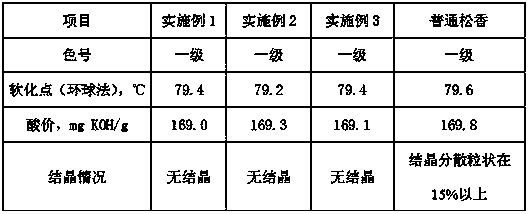

Examples

Embodiment 1

[0012] The preparation method of this anti-crystallization rosin is:

[0013] First put 0.8kg rosin into the reactor, heat and melt, then add 0.0001kg disodium hydrogen phosphate to the reactor, and stir at a temperature of 185°C; when the disodium hydrogen phosphate dissolves completely, Stop stirring, let stand for 10 minutes, discharge.

Embodiment 2

[0015] The preparation method of this anti-crystallization rosin is:

[0016] First put 0.9kg rosin into the reactor, heat and melt, then add 0.0003kg disodium hydrogen phosphate to the reactor, and stir at a temperature of 200°C; when the disodium hydrogen phosphate dissolves completely, Stop stirring, discharging, after standing for 13 minutes, discharging.

Embodiment 3

[0018] The preparation method of this anti-crystallization rosin is:

[0019] First put 0.1kg rosin in the reactor, heat and melt, then add 0.0005kg disodium hydrogen phosphate to the reactor, and stir at a temperature of 215°C; when the disodium hydrogen phosphate dissolves completely, Stop stirring, let stand for 15 minutes, discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com