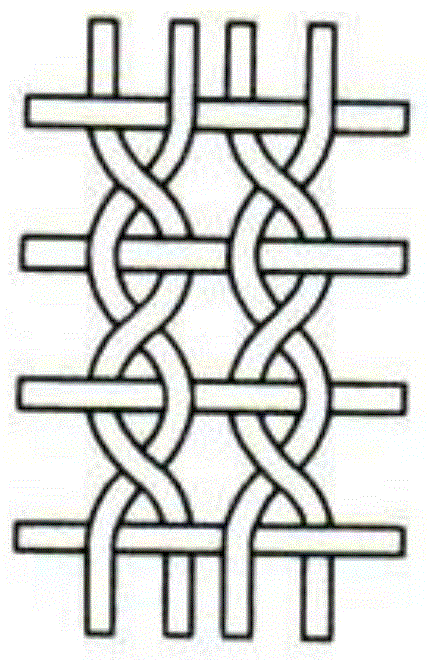

A weaving shedding device for a loom

A technology of opening device and loom, which is used in cam opening mechanism, textile, textile and papermaking, etc., can solve the problem that it cannot meet the user's requirements for high-speed, high-efficiency and high-quality use of weaving equipment, and the range of suitable mesh density is small. The problem of low loom speed, etc., achieves the effect of short interlaced movement time of warp, favorable for high-speed operation, and favorable for weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

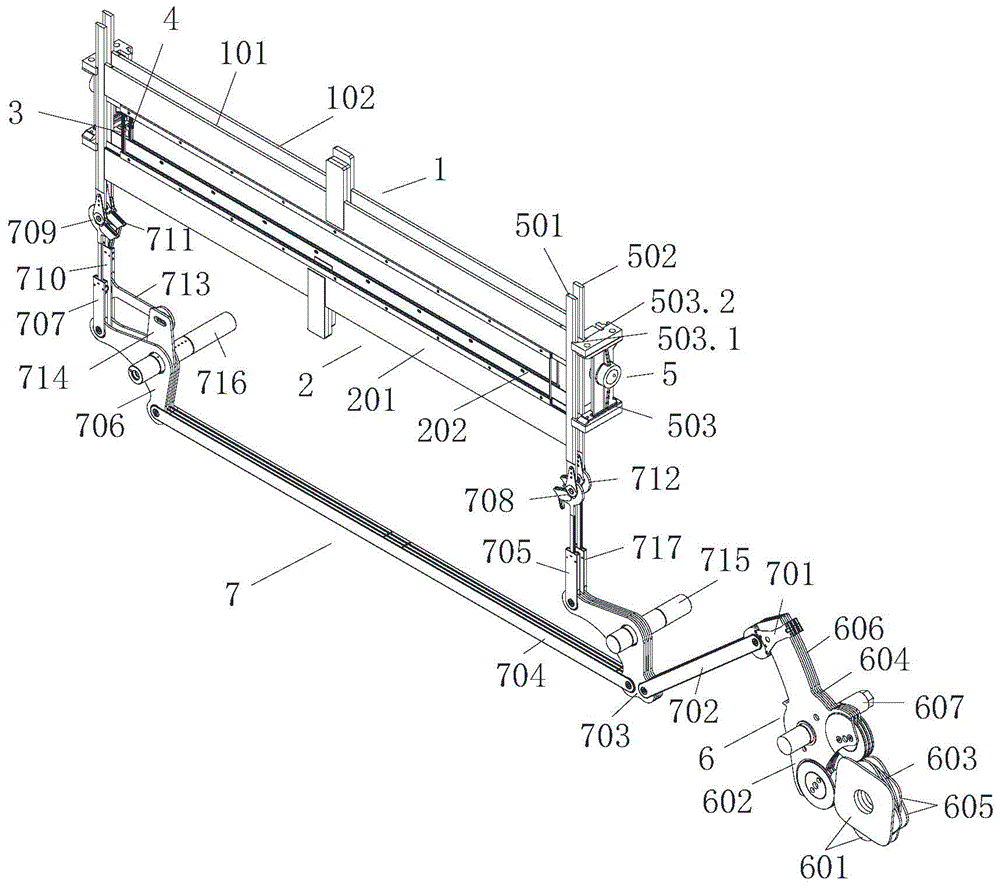

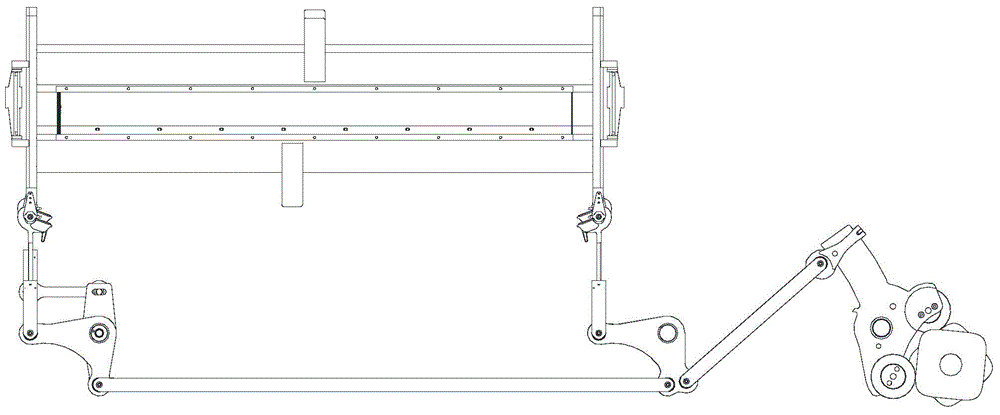

[0027] Such as Figure 2 to Figure 7Shown, a kind of opening device of twisted weaving of loom comprises heald frame mechanism, driving device 6, guiding mechanism 5 and transmission mechanism 7, heald frame upper beam 1 and heald frame lower beam 2, and heald frame upper beam 1 includes the first upper The heald frame 101 and the second upper heald frame 102, the heald frame lower beam 2 includes the first lower heald frame 201 and the second lower heald frame 202, the first upper heald frame 101 and the first lower heald frame 201 are located in the same vertical plane , the second upper heald frame 102 and the second lower heald frame 202 are located in the same vertical plane, between the first upper heald frame 101 and the first lower heald frame 201 there are several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com