A hinge that is easy to disassemble

A convenient disassembly and hinge technology, applied in door/window fittings, hinged panels, buildings, etc., can solve the time-consuming and labor-intensive disassembly, damage to the panel coating at the joint, and the operator's hinge support is connected with the door panel and the cabinet or box Position misalignment and other problems, to achieve the effect of firm connection and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

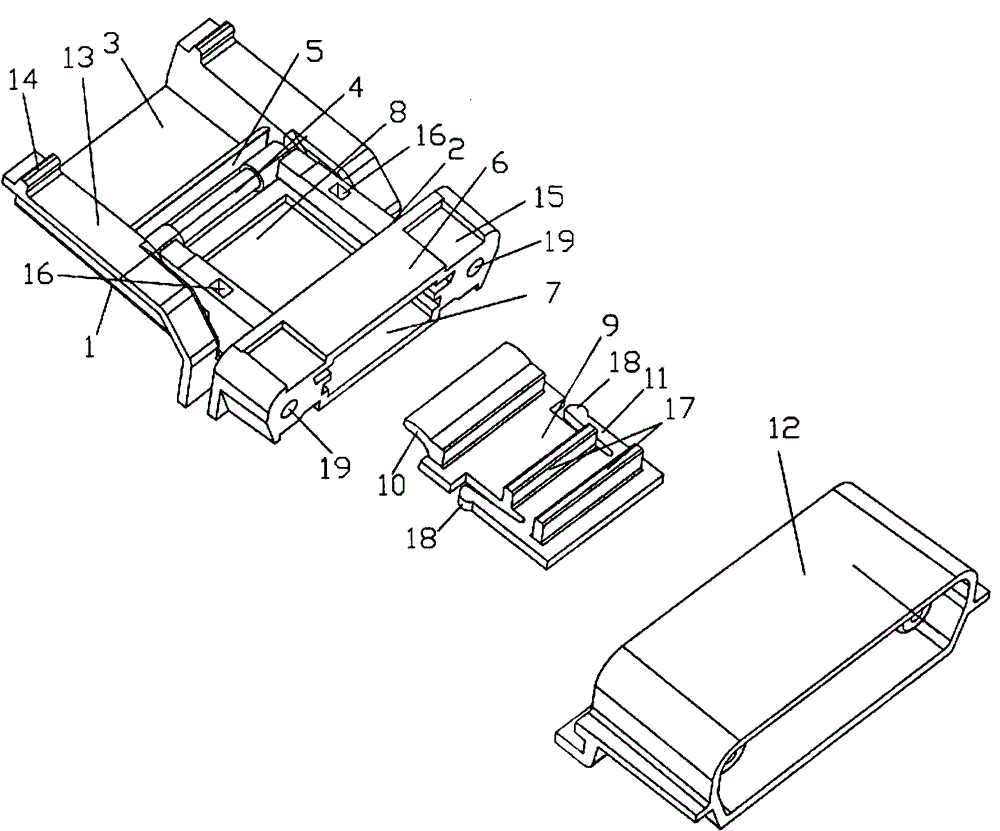

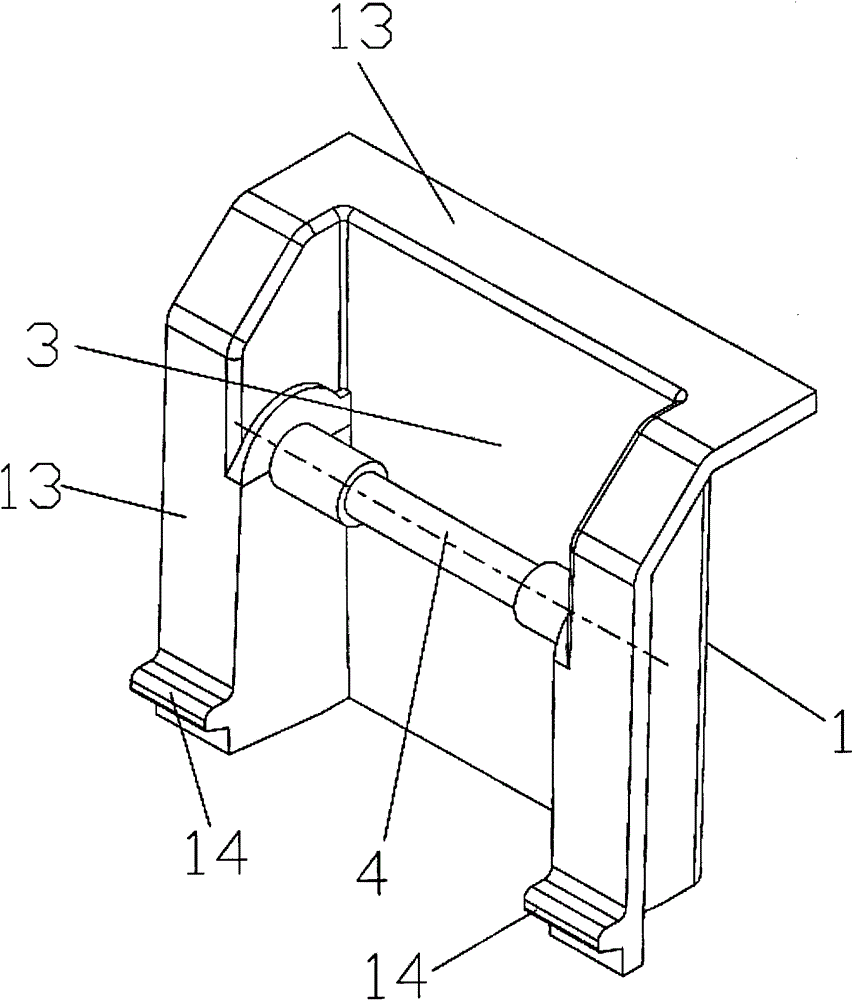

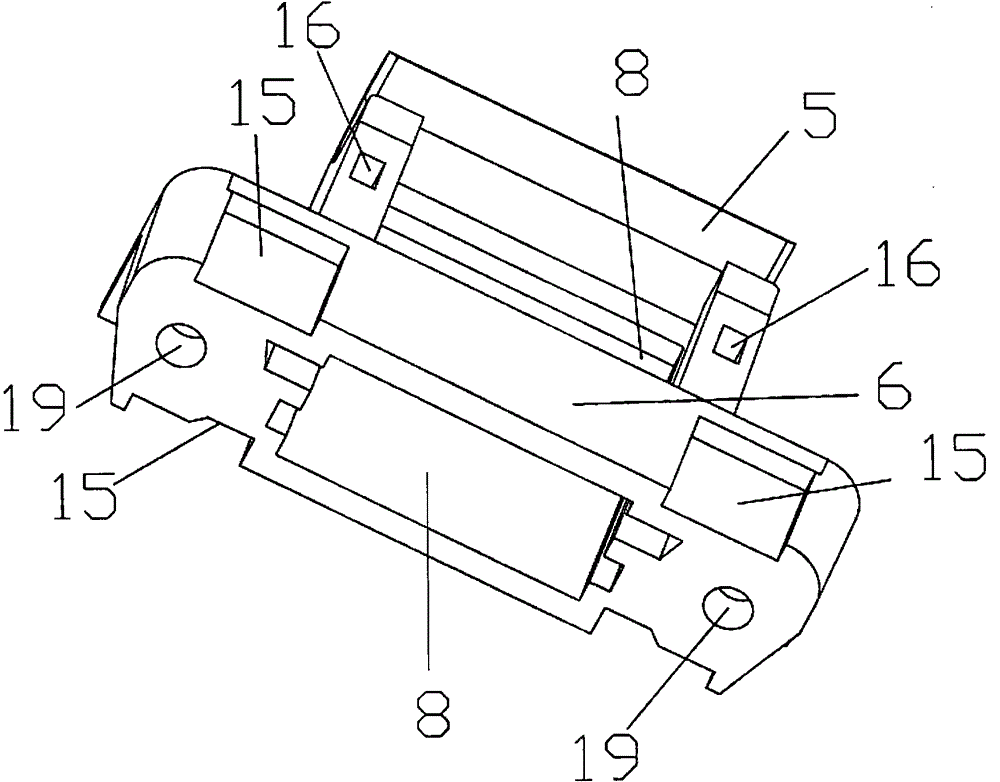

[0014] please see Figure 1 to Figure 4 A hinge that is easy to disassemble is shown, including a first hinge support 1 and a second hinge support 2, the first hinge support 1 is provided with a through groove 3, and a fixed shaft is arranged between the two side walls of the through groove 3 4. The diameters of the shaft sections at both ends of the fixed shaft 4 are equal and greater than the diameter of the shaft section in the middle of the fixed shaft 4. There is a gap between the fixed shaft 4 and the bottom of the through groove 3. One end of the second hinge support 2 is provided with a The fixed shaft 4 rotates the hook 5 that is socketed, and the other end of the second hinge support 2 is provided with a sleeve joint 6, and the end surface of the sleeve joint 6 is provided with a through hole 7, and the through hole 7 is opened on the hook 5 and the sleeve joint. The clamping slots 8 between the 6 are connected, and the clamping slot 8 is clamped with a hook anti-off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com