Cooling device for natural gas oil injection screw rod compressor

A technology for screw compressors and cooling devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. The exhaust temperature of the machine cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

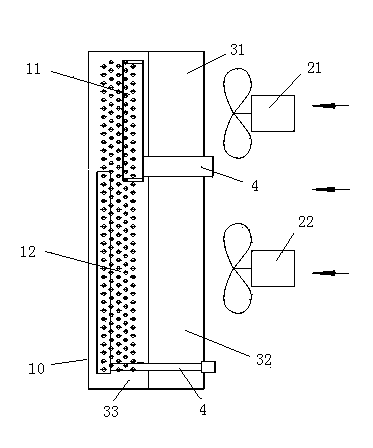

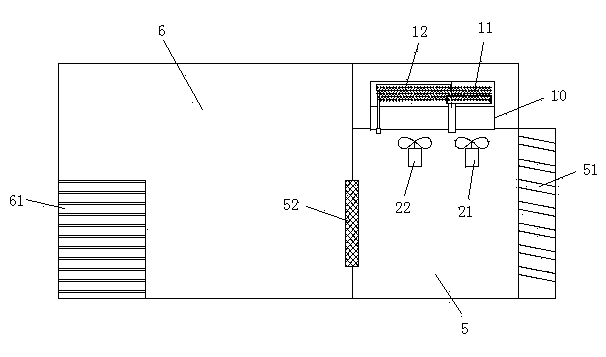

[0016] like Figure 1-Figure 2 As shown, a cooling device for a natural gas oil-injected screw compressor provided by an embodiment of the present invention includes a ventilation chamber 5, a cooling casing 10 and an air side cooler 11 respectively installed in the ventilation chamber 5 , oil side cooler 12, cooling fan, described ventilation cavity 5 is provided with air vent, it is characterized in that:

[0017] The inner cavity of the cooling enclosure 10 is divided into an air outlet channel 33 and two air inlet channels 31, 32 by the partition plate 4, and the outlets of the two air inlet channels 31, 32 are drawn out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com