Checking tool for checking embedded screws

A technology of pre-embedded screws and inspection tools, which is applied in the direction of mechanical diameter measurement, etc., can solve problems such as inconvenient operation, influence of mold ejection, and whitening of ejection of plastic products, and achieve the effect of simple device, stable and reliable work, and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

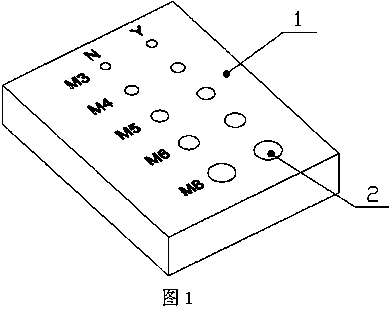

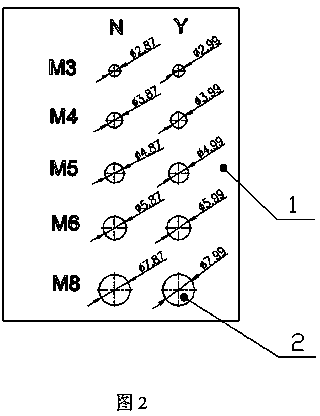

[0009] See attached figure 1 , figure 2 , The inspection tool for embedded screws of the present invention includes: a mounting plate 1 and an embedded screw detection hole 2 . In order to ensure the accuracy requirements of the embedded screw detection hole diameter, 10 embedded screw detection holes 2 are machined on the mounting plate 1 through slow wire cutting, and the standard embedded screw size within the range of M3 to M8 can be adjusted. detection. The size of the pre-embedded screw detection hole 2 corresponds to different tolerance ranges. When the embedded screw is in use, according to the specification of the embedded screw, according to the type marked on the mounting plate 1, it is put into the embedded screw detection hole 2 for detection. If the pre-embedded screw can pass through the detection hole 2 on the mounting plate 1, it means that the size of the pre-embedded screw meets the tolerance requirements of the design, and it is a qualified part; The s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap