Metal trap and catalytic cracking method

A metal trapping agent and catalytic cracking technology, applied in the field of metal trapping agents, can solve the problems of deteriorating product distribution, zeolite damage, etc., and achieve the effects of improving the yield of liquid products, slowing down damage, and reducing the yield of dry gas and coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

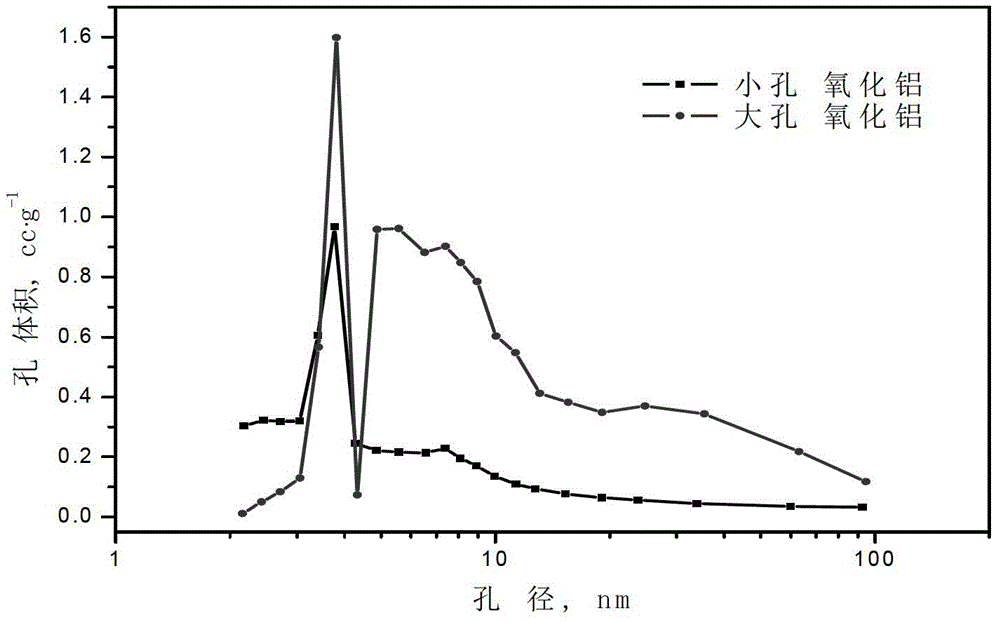

[0066] This example is used to illustrate the preparation process of the metal scavenger provided by the present invention.

[0067] (1) Add small-pore alumina A into deionized water, and after uniform dispersion, add hydrochloric acid, and obtain the first slurry after contacting for 30 minutes. The pH value of the first slurry is 1.1, and the solid content of the slurry is 15% by weight;

[0068] (2) Then add deionized water-dispersed MgO slurry (containing MgO750g) to the first slurry, and control the temperature at 55°C for 60 minutes to obtain the second slurry, the pH of the second slurry is 9.6, The solid content is 28% by weight;

[0069] (3) Then add macroporous alumina to the second slurry to obtain the third slurry, and contact at 10-40°C for 15 minutes;

[0070] (4) After the third slurry is spray-dried and shaped, it is directly calcined at 550°C / 2h to obtain a solid;

[0071] (5) At room temperature (10-40°C), contact 920g of the solid with 0.35L of a water-sol...

Embodiment 2-8

[0075] Examples 2-8 are used to illustrate the preparation process of the metal scavengers provided by the present invention.

[0076] Metal scavengers A2-A8 were prepared according to the method of Example 1, except that the formula, preparation parameters and wear index are listed in Table 2.

Embodiment 9

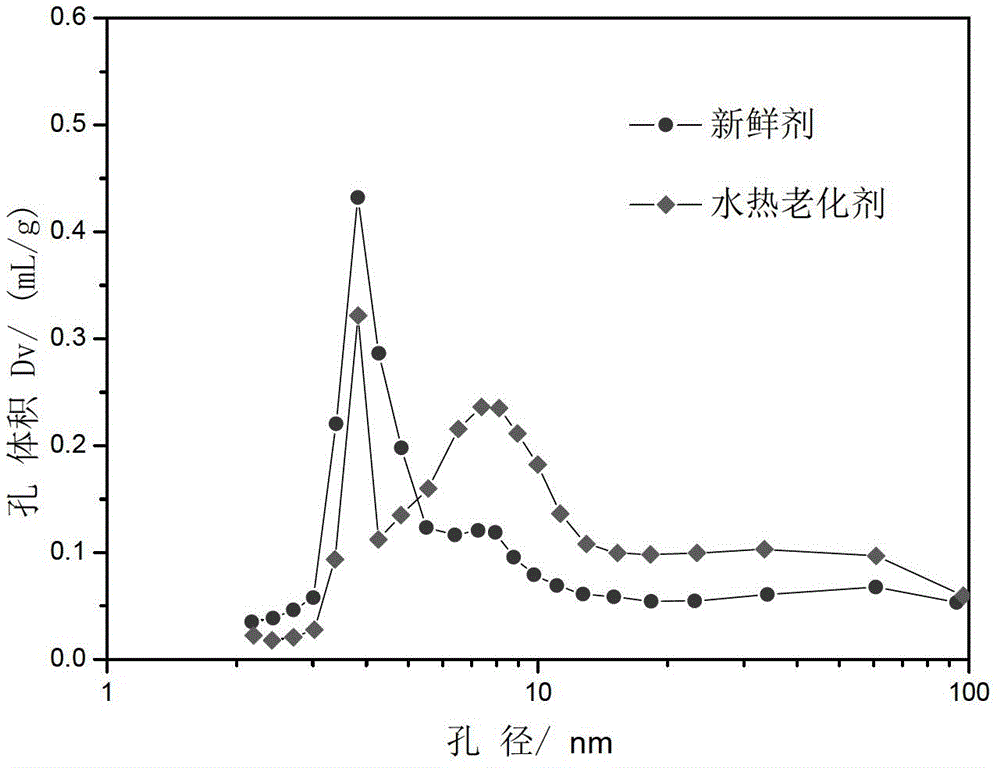

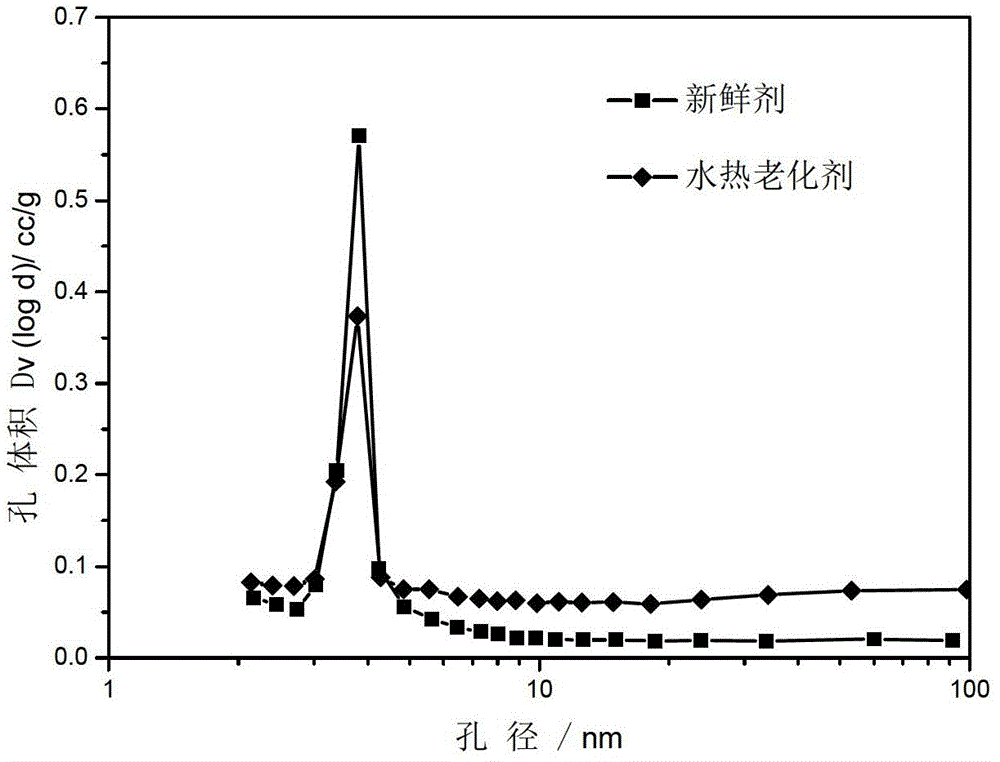

[0111] Example 9 is used to illustrate the heavy metal pollution method of the mixture of metal trapping agent and industrial cracking catalyst and the catalytic cracking performance of the metal trapping agent of the present invention for catalytic cracking.

[0112] First analyze the solid content of the industrial cracking catalyst C and the metal trapping agent A1 provided by the present invention, then physically mix with dry basis to obtain the catalyst mixture, and the catalyst mixture is first subjected to cycle pollution (to deposit Ni and V) on the cycle aging device, The theoretical amount of Ni and V on the catalyst mixture after the cycle pollution (that is, the calculated content, there will be some errors in reality, but it does not affect the results of the present invention) is shown in Table 6, wherein,

[0113] The recycling pollution step includes: the catalyst mixture introduces heavy metals (Ni and After V), the catalyst mixture introduced with heavy meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com