Metal trapping agent and its preparation method and catalytic cracking method

A technology of metal trapping agent and magnesium oxide, which is applied in the preparation of metal trapping agent, and in the field of catalytic cracking using the aforementioned metal trapping agent, can solve the problems of molecular sieve damage, catalytic cracking product distribution damage, etc., and achieve optimal physical and chemical properties, Good metal trapping effect, reduced dry gas and/or coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the metal scavenger described in the present invention can be prepared by various methods, and the inventors of the present invention have found that the metal scavenger with the bulk density prepared by the following preparation method of the present invention is within the scope of the present invention Compared with the metal trapping agent prepared by other preparation methods within the above range, the metal trapping agent has better metal trapping effect.

[0029] In the second aspect, the present invention also provides a method for preparing a metal trapping agent, the preparation method comprising: the first aluminum source, magnesium aluminum sol, magnesium source, optional clay, optional acid, and An optional solvent is mixed to prepare a mixed slurry, dried and roasted to obtain the metal collector; wherein, the molar ratio of Mg:Al in the magnesium-aluminum sol is (1.5-6):(1-2), preferably (4-6):1, and the molar ratio of Al:Cl in ...

preparation example

[0104] For illustrating the aluminum sol adopted in the present invention, magnesium aluminum sol and preparation method thereof:

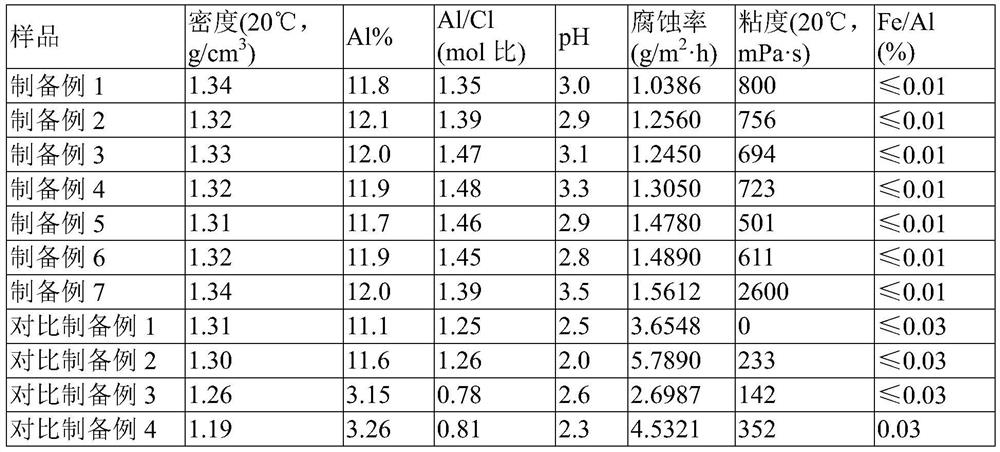

[0105] The test items and test methods involved in the following preparation examples are described as follows:

[0106] The free chloride ion content of the aluminum sol is determined by the method of sedimentation. Use ammonia water to adjust the pH value of the aluminum sol to 5-6. The aluminum sol has a flocculent precipitate, separate the precipitate, and measure the chloride ion content of the supernatant.

[0107] The density of the aluminum sol was measured by a glass densitometer (Shenzhen Dingxinyi Experimental Equipment Co., Ltd.).

[0108] The viscosity of the aluminum sol was measured by a rotational viscometer (Shanghai Hengping Scientific Instrument Co., Ltd., NDJ-1 rotational viscometer).

[0109] The content of elements in the aluminum sol is measured by XRF fluorescence analysis method (RIPP 117-90 standard method (see "Petroche...

preparation example 1

[0121] This preparation example illustrates the preparation method of the aluminum sol of the present invention.

[0122] (1) Carry out the first contact with 1mol metal aluminum (China Aluminum Corporation) and 1mol (HCl) hydrochloric acid, control the temperature of the first contact process to be 50°C, the first contact time is 3h, and the initial concentration of hydrochloric acid used is 32% by weight ;

[0123] (2) The mixture after the first contact was left at room temperature at 20°C for 6 hours, and then mixed with γ-Al 2 o 3 (Shandong Aluminum Plant) and η-Al 2 o 3 (Shandong Aluminum Works) carries out the second contact, the second contact temperature is 30 ℃, the second contact time is 4h, the gamma-Al calculated as aluminum 2 o 3 , η-Al in aluminum 2 o 3 The molar ratio to the metal aluminum in step (1) is 0.05:0.05:1. The physical and chemical properties of aluminum sol are listed in Table 1.

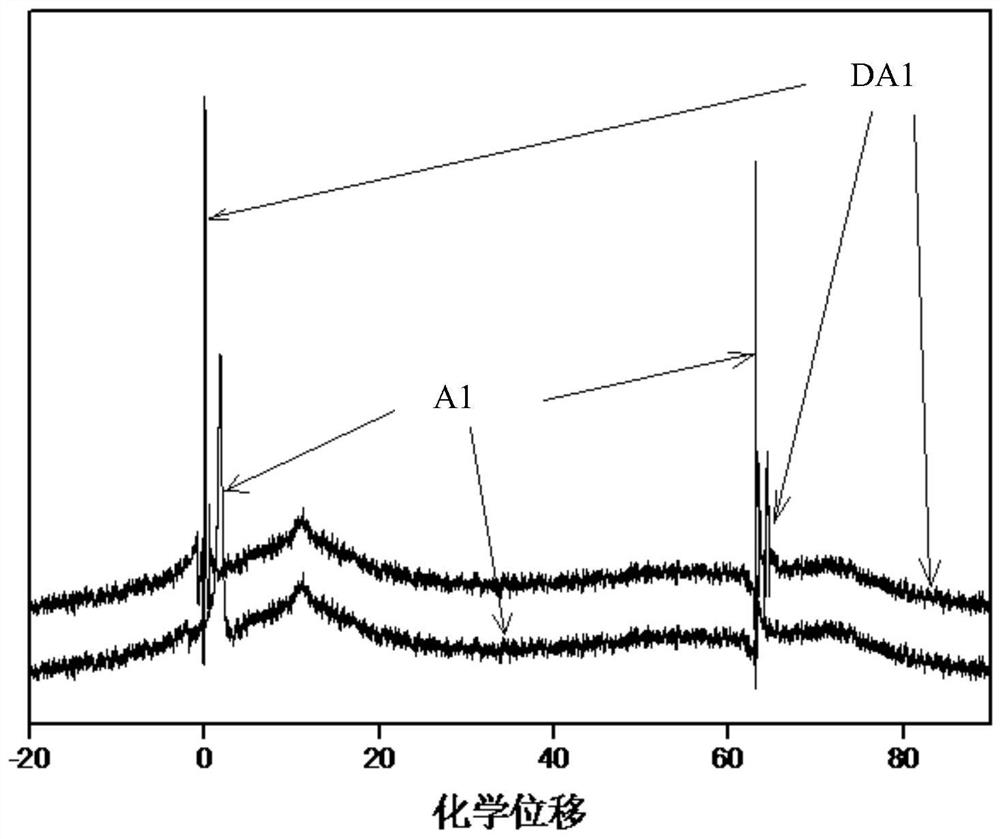

[0124] Aluminum sol (denoted as A1) was carried out 27 Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com