A metal trapping agent, its preparation method and application, and a catalytic cracking method

A metal trapping agent and catalytic cracking technology, which is applied in the field of metal trapping agents, can solve the problems of zeolite damage, deterioration of product distribution, etc., and achieve the effects of slowing down damage, increasing liquid product yield, and good metal trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] The preparation method of the metal trapping agent in the present invention can be carried out with reference to the prior art, and it can be prepared by conventional methods in the field. According to an embodiment of the present invention, the present invention provides a metal trapping agent The preparation method includes:

[0041] (1) The first slurry is obtained by mixing small pore alumina, macro pore alumina, deionized water and acid to prepare slurry;

[0042] (2) Contacting the first slurry with magnesium hydroxide and / or magnesium oxide to obtain a second slurry;

[0043] (3) The second slurry is spray-dried and then roasted;

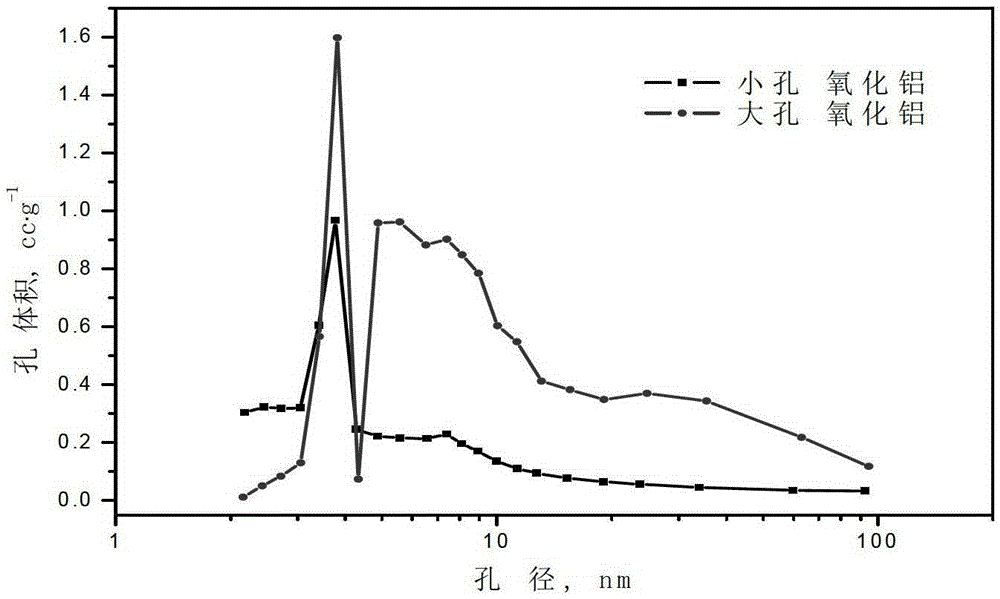

[0044] Wherein, based on the pore volume of 2-100nm pores, in the macroporous alumina, the pore volume of 2-5nm pores accounts for 20-35%, the pore volume of 5-10nm pores accounts for 25-45%, and the pore volume of 5-10nm pores accounts for 25-45%. The pore volume of the pores accounts for 20-50%; the pore volume of 2-5nm pores in the small p...

preparation Embodiment 1-4

[0096] Preparation Examples 1-4 are used to prepare the precursor of the phosphor-aluminum auxiliary agent of the present invention

preparation Embodiment 1

[0098] 1.25 kg of pseudo-boehmite (including Al 2 O 3 0.76 kg), 0.26 kg of Leytonite (0.2 kg on a dry basis) and 1.57 kg of deionized water for 30 minutes to obtain a slurry. Under stirring, add 1.69 kg of concentrated phosphoric acid to the slurry and increase the temperature to 70°C. After contacting for 45 minutes, the precursor P1 of phosphor-aluminum auxiliary agent was obtained. The material ratio is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com