Combined type long hose production mold

A long rubber hose and combined technology, which is applied in the direction of household appliances, tubular objects, and other household appliances, can solve the problems of high labor intensity and production efficiency of mold collision, so as to reduce labor intensity, prevent mold collision damage, reduce The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

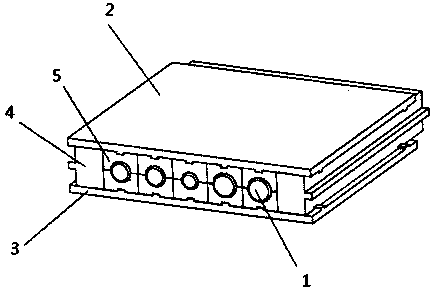

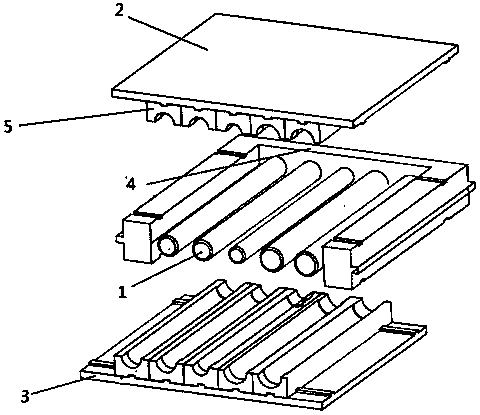

[0022] A combined long rubber hose production mold, including a template and a detachable and interchangeable core 1; it is characterized in that the template includes an upper template 2, a lower template 3, and a middle template 4; the upper template 2 and the lower template 3 are equipped with The cavity 5 is detachable and interchangeable; the middle template 4 is set as a frame structure, and the core 1 is arranged in the middle template 4 of the frame structure.

Embodiment 2

[0024] A combined long rubber hose production mold, similar to Example 1, the difference is that the core 1 is set in the middle formwork 4 of the frame structure to form a cantilever beam structure; the inside of the middle formwork 4 of the frame structure is provided with Evenly distributed circular grooves, the core 1 is set as a cylinder that matches the circular groove, and the core 1 of the cylinder is embedded in the circular groove on the inner side of the middle template 4 of the frame structure and tightened Form a cantilever beam structure; the cavity 5 is set as an independent structure set on the upper template 2 and the lower template 3; the upper template 2 and the lower template 3 are provided with a longitudinal boss on the surface connected to the cavity 5, and the cavity 5 The surface connected with the upper template 2 and the lower template 3 is provided with a longitudinal groove matching the longitudinal boss, and the upper template 2 and the lower templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com