A construction method of composite piles made of y-shaped three-dimensional drainage boards with strong cores and loose materials

A technology of bulk material piles and bulk materials, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of drainage board back belt, high cost, and small drainage range, so as to expand the drainage range and solve the problem of The effect of the back belt problem and the good drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

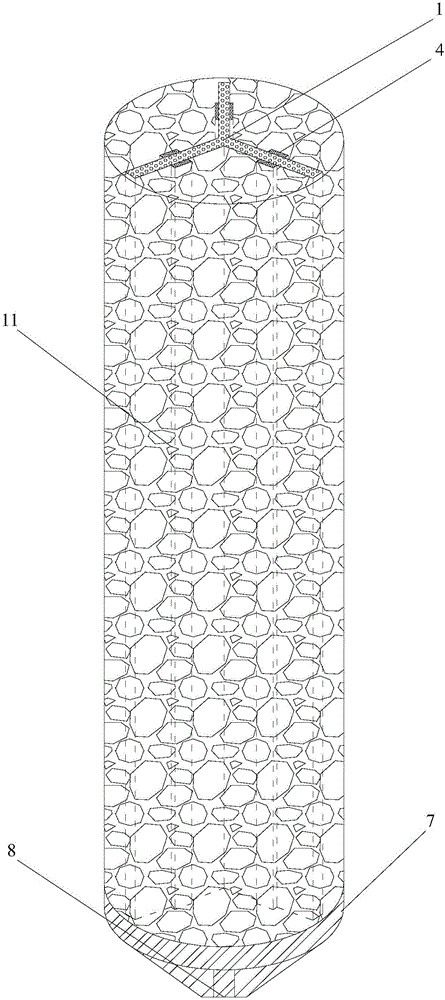

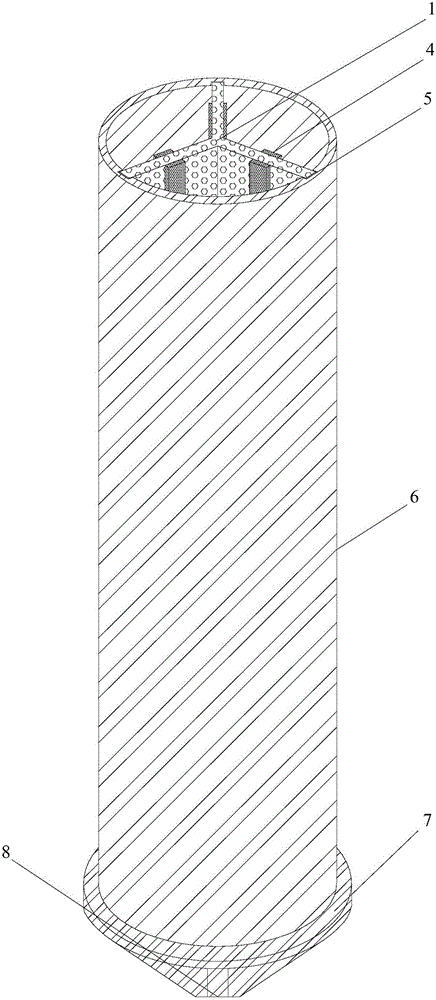

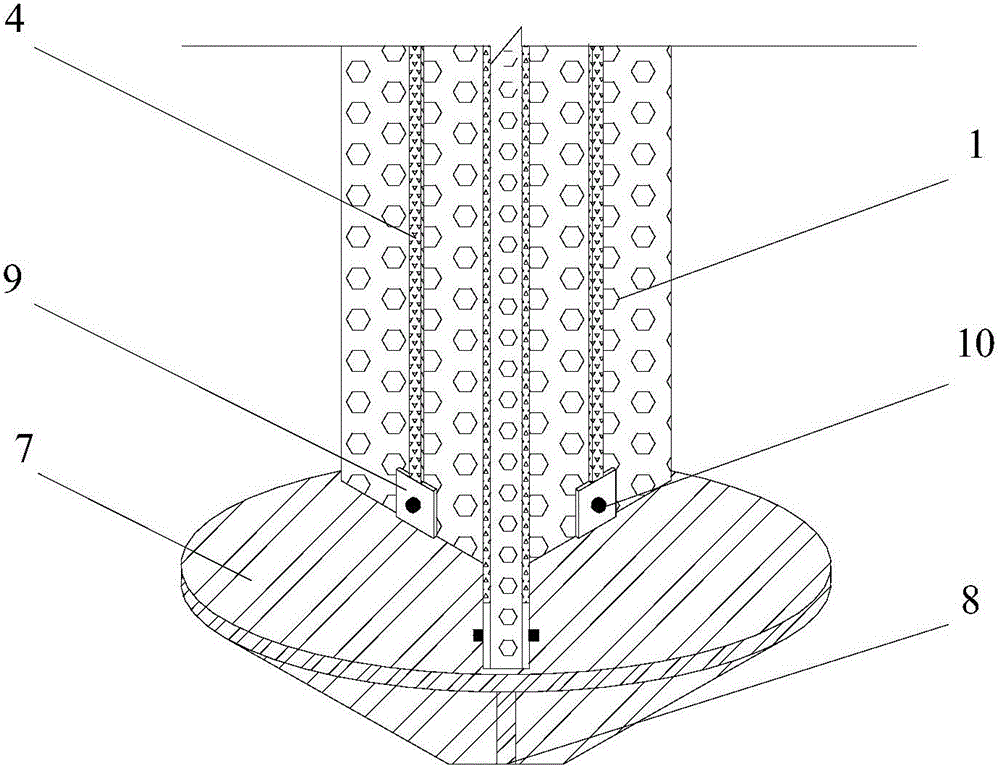

[0034] Implementation of the present invention refers to Figure 1 to Figure 5 As shown, the Y-shaped three-dimensional drainage board strength core loose material composite pile and its construction method, the three-dimensional drainage board core body is Y-shaped, that is, the side boards of the drainage board form an angle of 120° in two, and the outer membrane of the drainage board is set outside. At the same time, 6 flexible reinforcement strips are uniformly and symmetrically arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com