Completely chip-free spherical integral hydraulic hose metal joint structure and its production process

A technology of metal joints and hydraulic hoses, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, engine components, etc., can solve the problems of parts penetration or shedding, and achieve the elimination of leakage risks, perfect production and use , The effect of improving the parallelism accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

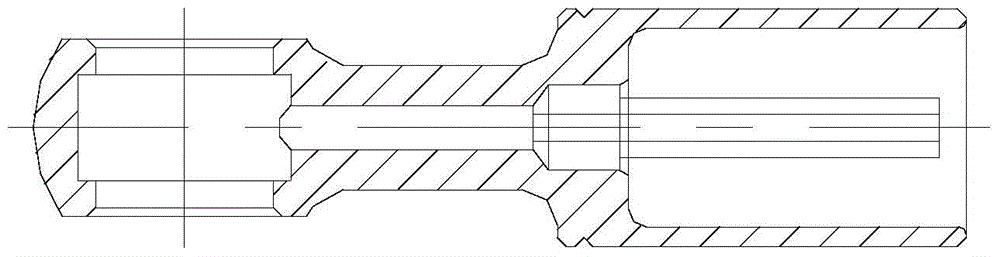

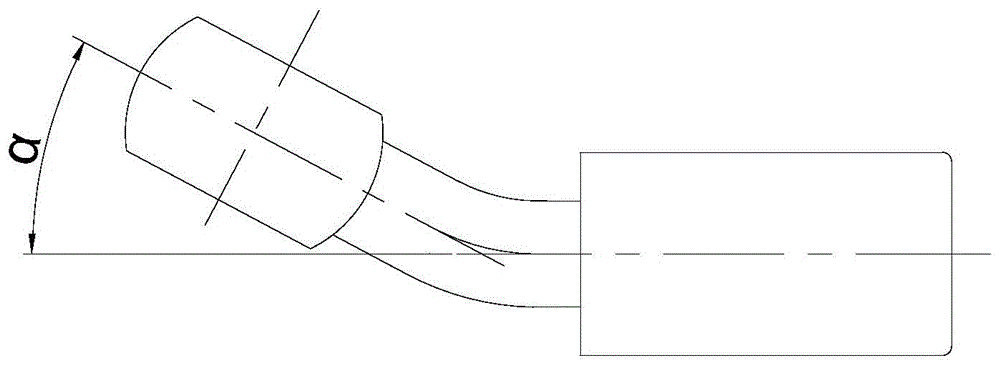

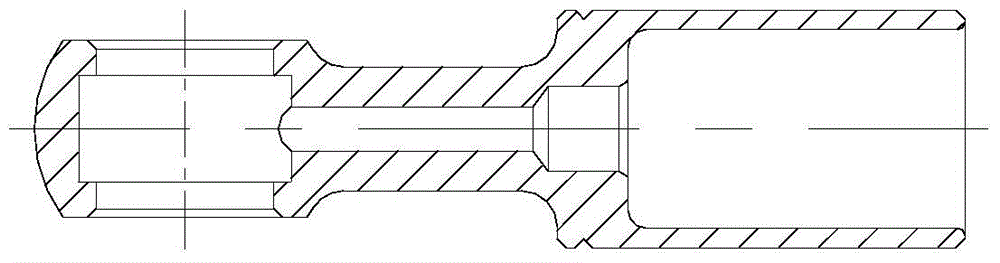

[0072] Such as Figure 5-Figure 7-12 , a fully chip-free ball type integral hydraulic hose metal joint structure, including a metal joint body 1 and a sleeve 2, the metal joint body 1 includes a ball joint 3, a tee structure through hole 4, a hollow liner core pipe 5, Lining core connecting pipe 6 and connecting rod 8, one end of the connecting rod 8 is a ball joint 3, the other end of the connecting rod 8 is connected to the sleeve 2, the inside of the connecting rod 8 is a hollow inner lining core pipe 5 and the lining core connecting pipe 6, wherein the lining core The connecting pipe 6 extends into the inside of the sleeve 2; the metal joint main body 1, the spherical joint 3, the through hole 4 of the tee structure, the hollow inner core tube 5, the core connecting tube 6 and the connecting rod 8 form an integral structure.

[0073] The connecting rod 8 has three diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com