Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as increased cost, difficulty in mass production, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments according to the present invention will be described.

[0046] Instructions are given in the following manner.

[0047] 1. Semiconductor device and manufacturing method of the embodiment

[0048] 1-1. Structure of semiconductor device

[0049] 1-2. Manufacturing method as the aforementioned example

[0050] 1-3. Problems in the preceding examples

[0051] 1-4. Manufacturing method of the example

[0052] 1-5. Outline of Embodiments

[0053] 2. Modification

[0054] 3. The present invention

[0055] 1. Semiconductor and manufacturing method of the embodiment

[0056] 1-1. Structure of semiconductor device

[0057] Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

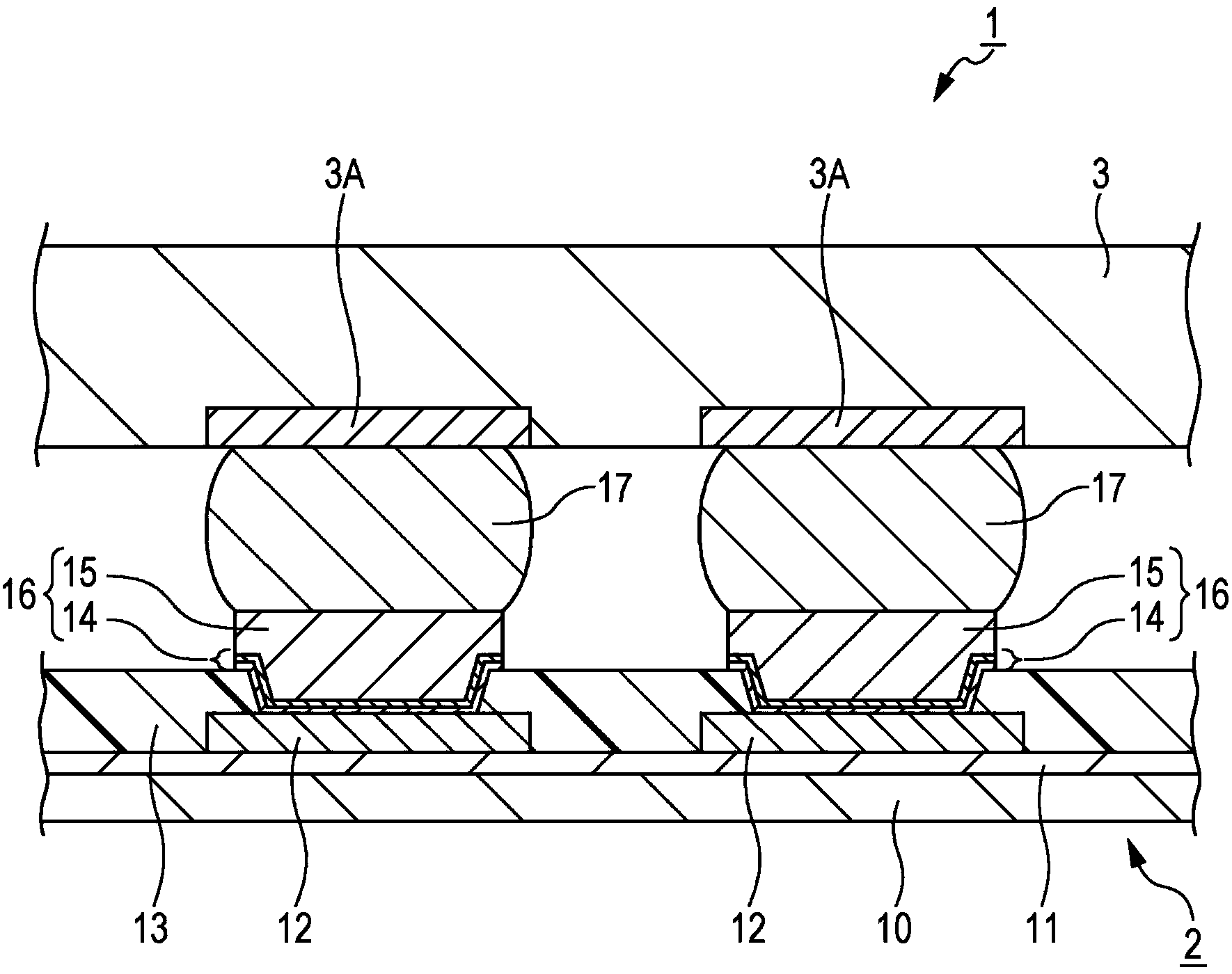

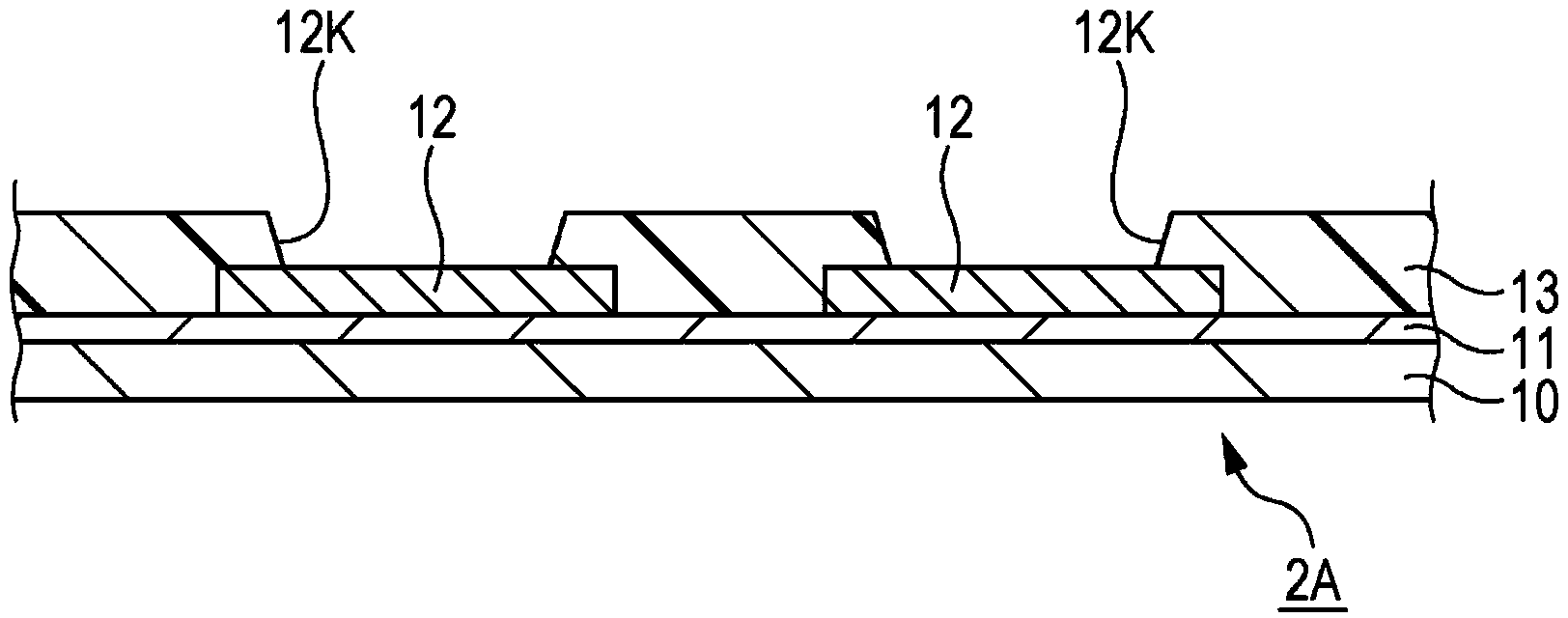

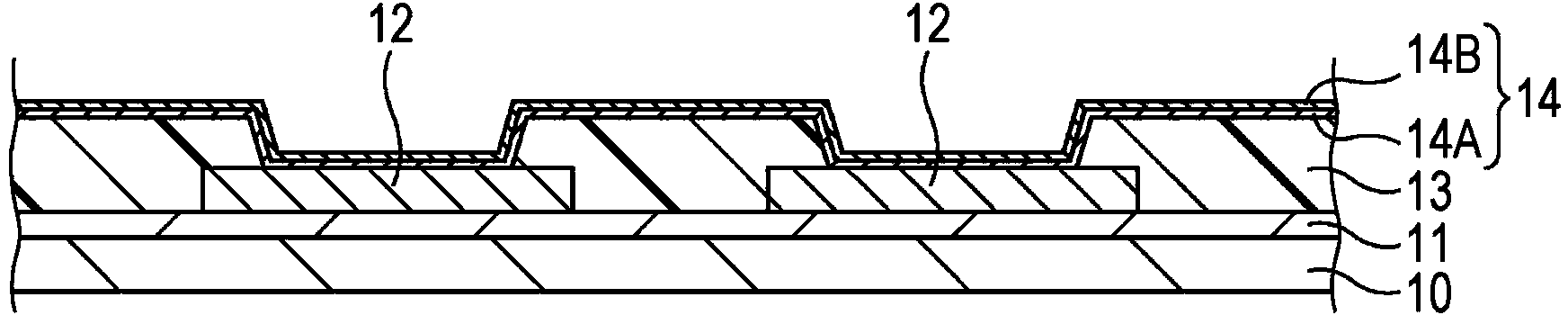

[0058] figure 1 is a schematic cross-sectional view of the semiconductor device 1 according to the embodiment.

[0059] First, as a premise, the semiconductor device 1 according to the embodiment is configured to ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com