Method for producing lactic acid

A kind of manufacturing method, the technology of lactic acid, is applied in the manufacture field of lactic acid, can solve the problem such as the unclear method that the LDH activity of Rhizopus genus is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

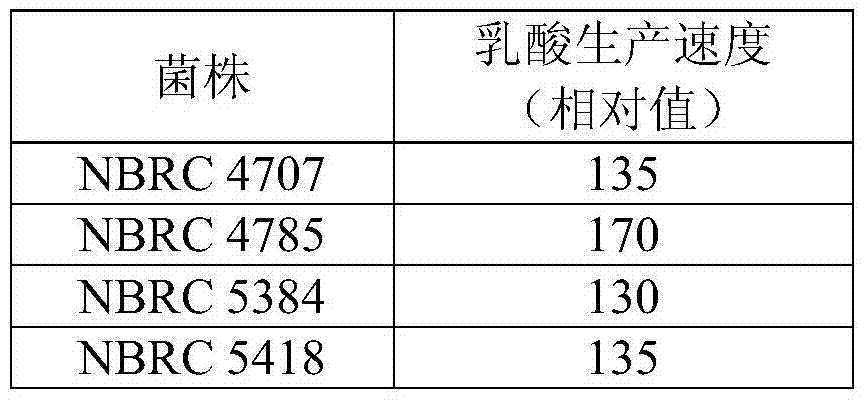

[0090] Examples are shown below to describe the present invention more specifically.

[0091] The preparation method of manufacturing example 1 spore suspension

[0092] Rhizopus oryzae ( Rhizopus oryzae) JCM14625 strain (=NBRC 5384) spore suspension freeze-preserved sample (-80°C) was inoculated with 1 platinum loop in PDA medium (Difco Potato Dextrose Agar, manufactured by Becton, Dickinson and Company), and cultured statically at 30°C 7 to 10 days. After visually confirming the growth of mycelia and the blackening of the ends of mycelium accompanied by sporulation, 30 to 40 mL of physiological saline was added thereto, and the mycelium and spores were transferred together using a platinum ring to a 50-mL capped centrifuge tube (manufactured by Greiner ), mixed vigorously in the tube. The mixed spore suspension was filtered through a 3GP100 cylindrical funnel-shaped glass filter (manufactured by Shibata Scientific Co., Ltd.) to obtain a spore liquid. The number of spo...

manufacture example 2

[0093] Preparation of Manufacturing Example 2 Mycelia

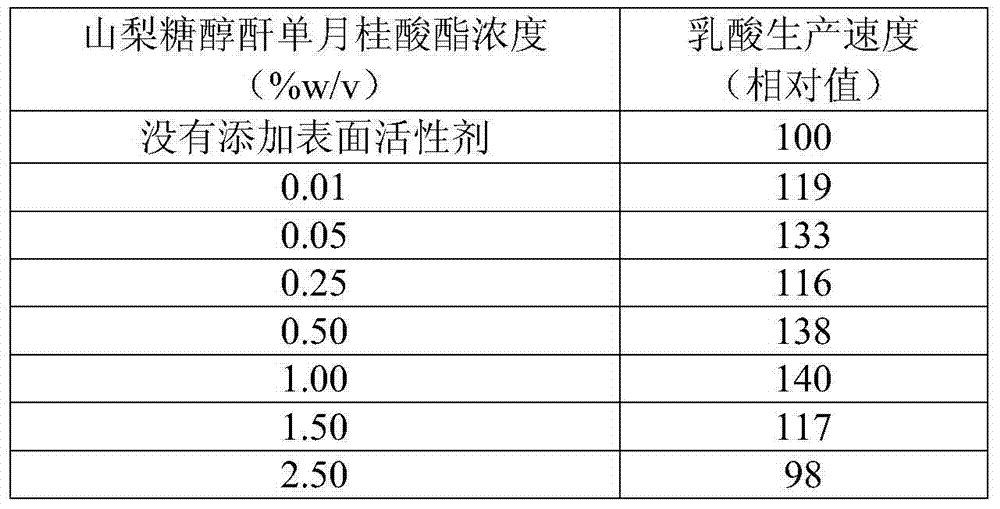

[0094] To a baffled Erlenmeyer flask (manufactured by Asahi Glass Co., Ltd.) with a volume of 200 mL, 80 mL of PDB medium was added without adding the surfactant described below or at a final concentration of 0.5% (w / v). The Rhizopus oryzae prepared in 1 ( Rhizopus oryzae ) spore suspension to become 1×10 3 Each-spore / mL-medium was inoculated, and then cultured with agitation at 170 rpm for 3 days at 27°C. Since the mycelia remained on the filter, the above-mentioned culture was filtered through a pre-sterilized stainless steel sieve with a mesh size of 250 μm (manufactured by As One), and the bacterial cells were collected on the filter.

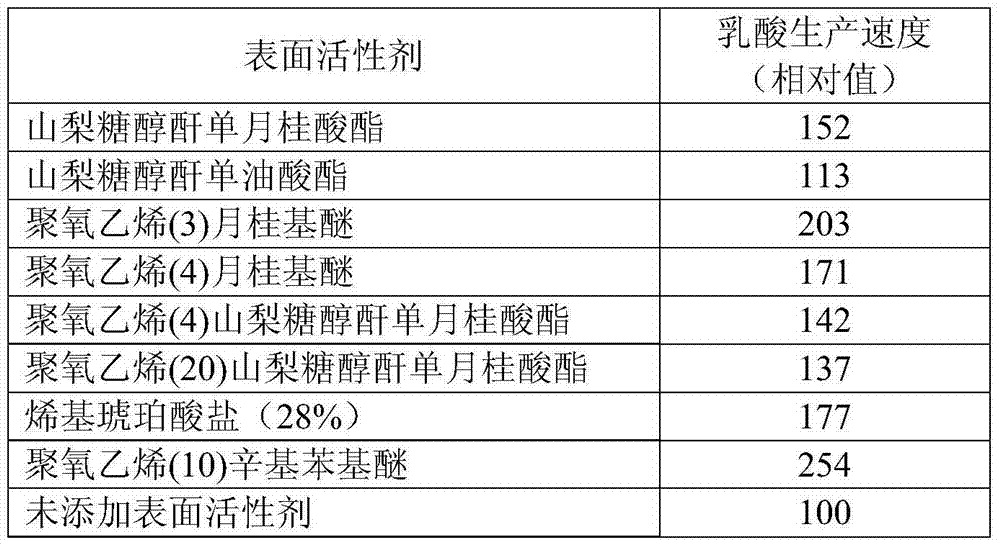

[0095] Surfactant

[0096] Sorbitan monolaurate: RHEODOL (registered trademark) SP-L10 (Kao)

[0097] Sorbitan monooleate: RHEODOL (registered trademark) SP-O10V (Kao)

[0098] Polyoxyethylene (3) lauryl ether: EMULGEN (registered trademark) 103 (Kao)

[0099] Polyoxyethylene ...

manufacture example 3

[0108] Proliferation of production example 3 mycelium

[0109] 100mL of inorganic culture solution (composition: 10% glucose, 0.1% ammonium sulfate, 0.06% potassium dihydrogen phosphate, 0.025% magnesium sulfate heptahydrate, 0.009% zinc sulfate heptahydrate, 3.0-4.0 g (wet weight) of recovered bacteria were inoculated in 5.0% calcium carbonate (all concentrations are % (w / v)), and cultured with stirring at 220 rpm for about 40 hours at 27°C. Next, the culture cultured with the above-mentioned inorganic culture solution was filtered with a stainless steel mesh filter holder (manufactured by MILLIPORE) sterilized in advance, and bacterial cells were collected on the filter. Further, the bacterial cells were washed with 100 mL of physiological saline on the filter holder. Physiological saline used for washing was removed by suction filtration. The obtained bacterial cells were used for the following LDH activity evaluation and lactic acid fermentation productivity evaluation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com