Method for growing laminated double-metal hydroxide on surface of any substrate

A layered bimetallic, hydroxide technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of difficulty in ensuring the regularity of LDH nano-rolls, large environmental impact, and cumbersome operations, so as to shorten the preparation time. Long-lasting, widely applicable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 0.1 g of dopamine and 0.1 g of polyethyleneimine with a molecular weight of 600 were added to 50 mL of an aqueous solution of tris with a concentration of 10 mmol / L and stirred to dissolve. The silica fiber membrane was immersed in the above solution and shaken for 12 hours, so that the silica surface was uniformly covered with a dopamine / polyethyleneimine modified layer.

[0032] In 50mL deionized water, add 1.55g CoSO 4 , 0.4g Al 2 (SO 4 ) 3 And 2.592g urea was stirred and dissolved. Add the surface-modified silica fiber membrane into the above solution and fully immerse.

[0033] The above system was moved into a hydrothermal kettle, and placed in a vacuum oven for crystallization at 105°C for 3h. After the reaction is finished, take it out after cooling down to room temperature, wash it several times with deionized water, and finally dry it in vacuum to obtain a silica fiber membrane with layered double metal hydroxide grown on the surface.

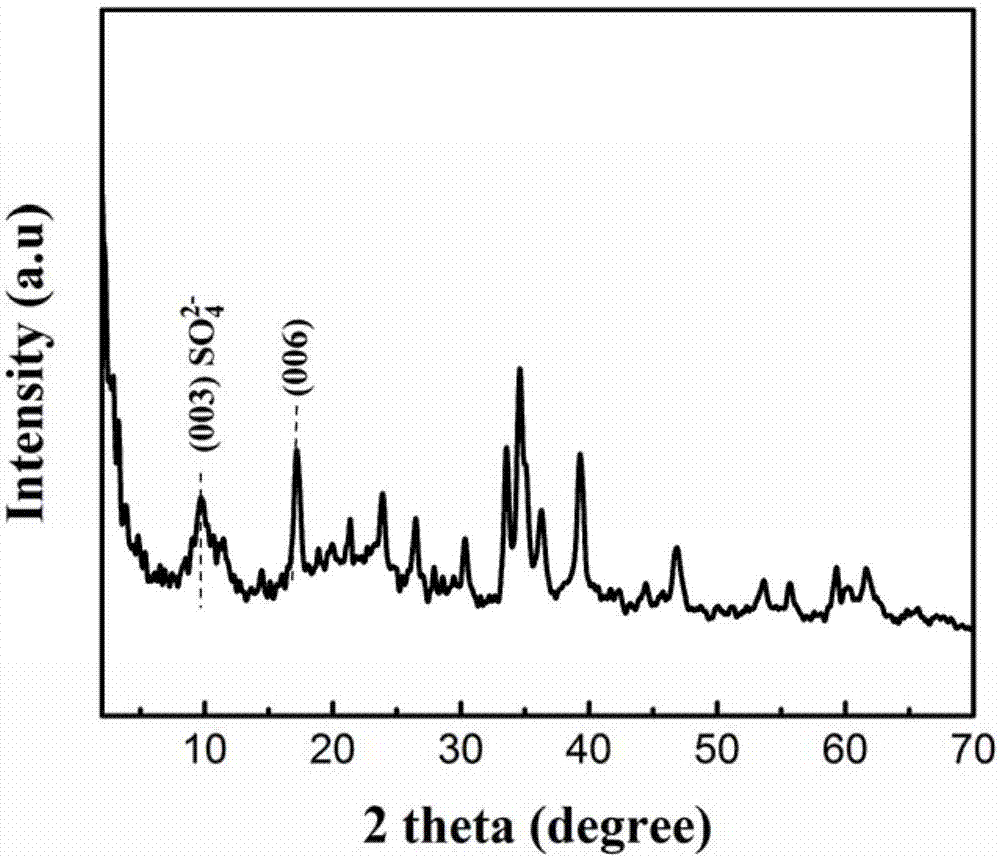

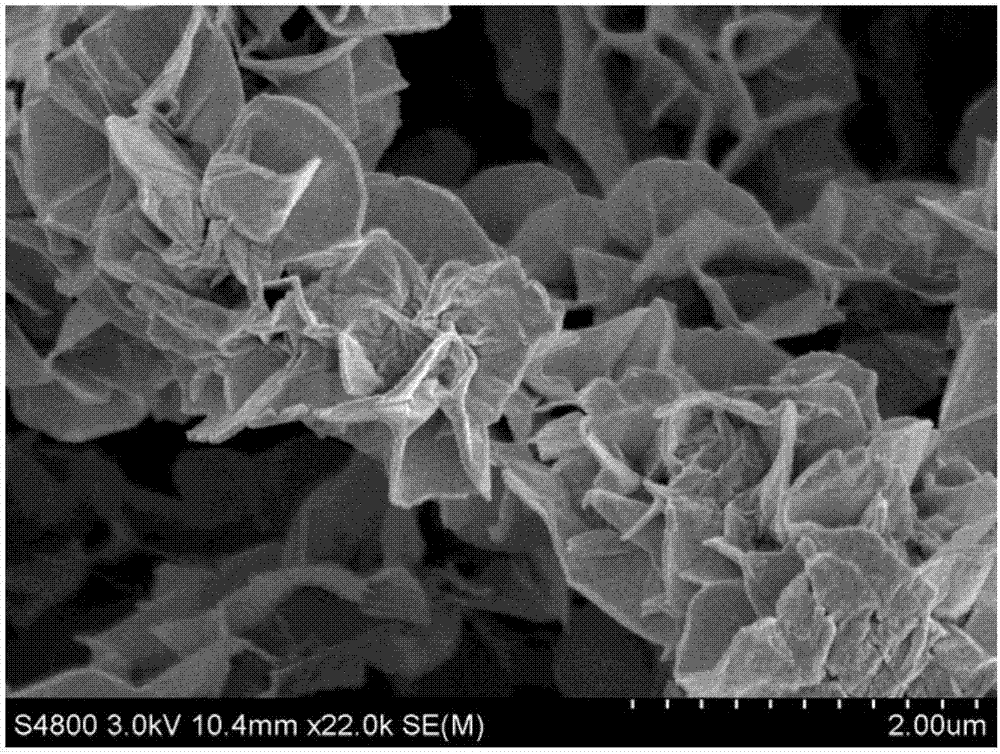

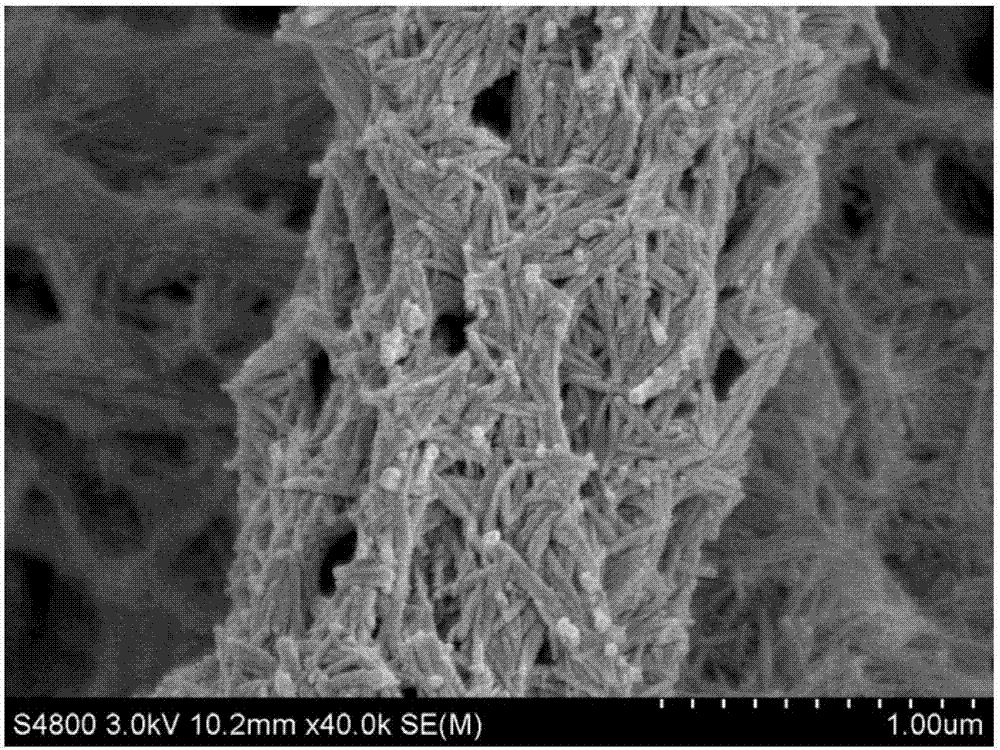

[0034] The XRD sp...

Embodiment 2

[0037] 0.2 g of dopamine and 0.1 g of polyethyleneimine with a molecular weight of 600 were added to 50 mL of an aqueous solution of tris with a concentration of 45 mmol / L and stirred to dissolve. The silica fiber membrane was immersed in the above solution and shaken for 10 h, so that the silica surface was uniformly covered with a dopamine / polyethyleneimine modified layer.

[0038] In 50mL deionized water, add 1.6g CoSO 4 , 0.5g Al 2 (SO 4 ) 3 and 1.85g of urea were stirred and dissolved. Add the surface-modified silica fiber membrane into the above solution and fully immerse.

[0039] The above system was moved into a hydrothermal kettle, and placed in a vacuum oven for crystallization at 108°C for 6h. After the reaction is finished, take it out after cooling down to room temperature, wash it several times with deionized water, and finally dry it in vacuum to obtain a silica fiber membrane with layered double metal hydroxide grown on the surface.

[0040] The XRD spec...

Embodiment 3

[0043] 0.15 g of dopamine and 0.2 g of polyethyleneimine with a molecular weight of 1800 were added to 50 mL of an aqueous solution of tris with a concentration of 10 mmol / L and stirred to dissolve. The silica fiber membrane was immersed in the above solution and shaken for 10 h, so that the silica surface was uniformly covered with a dopamine / polyethyleneimine modified layer.

[0044] In 50 mL of deionized water, add 1.3 g of CoCl 2 , 0.35g AlCl 3 And 2.49g urea was stirred and dissolved. Add the surface-modified silica fiber membrane into the above solution and fully immerse.

[0045] The above system was moved to a hydrothermal kettle, and placed in a vacuum oven for crystallization at 110° C. for 12 hours. After the reaction is finished, take it out after cooling down to room temperature, wash it several times with deionized water, and finally dry it in vacuum to obtain a silica fiber membrane with layered double metal hydroxide grown on the surface.

[0046] The XRD s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com