Gene engineering bacterium for high-yield hyaluronic acid and construction method and application of gene engineering bacteria

A technology of genetically engineered bacteria and hyaluronic acid, which is applied in the field of genetically engineered bacteria with high yield of hyaluronic acid and its construction, can solve the problems of hidden safety hazards, restricted development, and expensive prices for people with protein allergies, and achieve good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

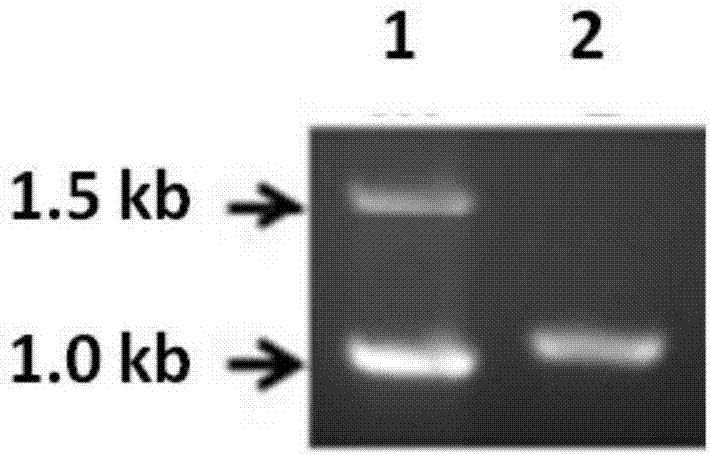

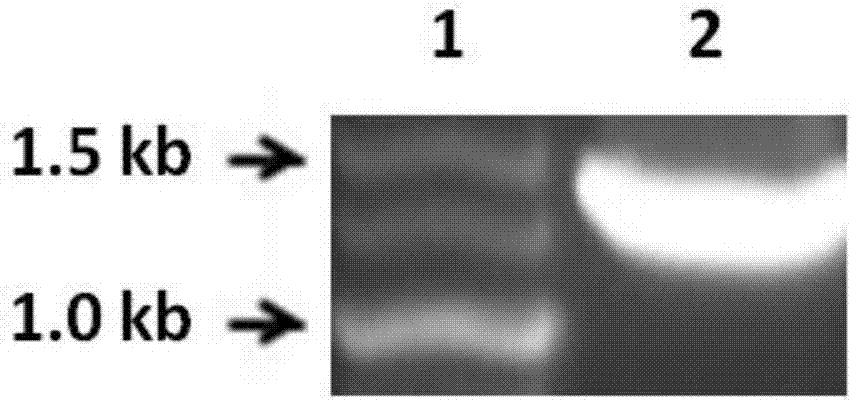

[0052] Example 1: Construction of ldh knockout recombinant strain Cg-△ldh (1) by single exchange homologous recombination

[0053] The construction of the recombinant bacterial strain Cg-△ldh (1) comprises the following steps:

[0054] 1. Construction of Corynebacterium glutamicum suicide plasmid pK18dLDH

[0055] Using the DNA genome of Corynebacterium glutamicum ATCC13032 as a template, PCR was performed with dLDH-F and dLDH-R as primers to obtain a fragment of about 700 bp in the middle of the lactate dehydrogenase gene ldh, and the product was purified as a homology arm;

[0056] Using the plasmid pK18mobsacB (referring to CN105420154A) as a template, and using pK18-F and pK18-R as primers to carry out PCR, amplify a fragment containing the Escherichia coli replication initiation site sequence ori sequence and the kanamycin resistance gene Kan sequence, and purify the product;

[0057] The above two fragments were ligated into a circular plasmid using the Gibson Assembly...

Embodiment 2

[0073] Example 2: Construction of ldh knockout recombinant strain Cg-△ldh by double exchange homologous recombination (2)

[0074] The construction of the recombinant bacterial strain Cg-△ldh (2) comprises the following steps:

[0075] 1. Construction of recombinant plasmid pK18mobmobsacB-dldh

[0076] Pick wild Corynebacterium glutamicum as a template, use dLDH-1 / dLDH-2 and dLDH-3 / dLDH-4 as primers to amplify the sequence of about 700bp upstream and downstream of the ldh gene in the genome, and purify the product ;

[0077] The plasmid pK18mobmobsacB was double digested with EcorI / XbaI, and the product was purified. The digested plasmid, the upstream fragment and the downstream fragment were subjected to Gibson Assembly ligation reaction to obtain the recombinant plasmid pK18mobmobsacB-dldh.

[0078] Primers were synthesized by Platinum Biotechnology (Shanghai) Co., Ltd., dissolved in sterile water and diluted to 10 μM for use. Phanta polymerase Mix used in PCR amplificat...

Embodiment 3

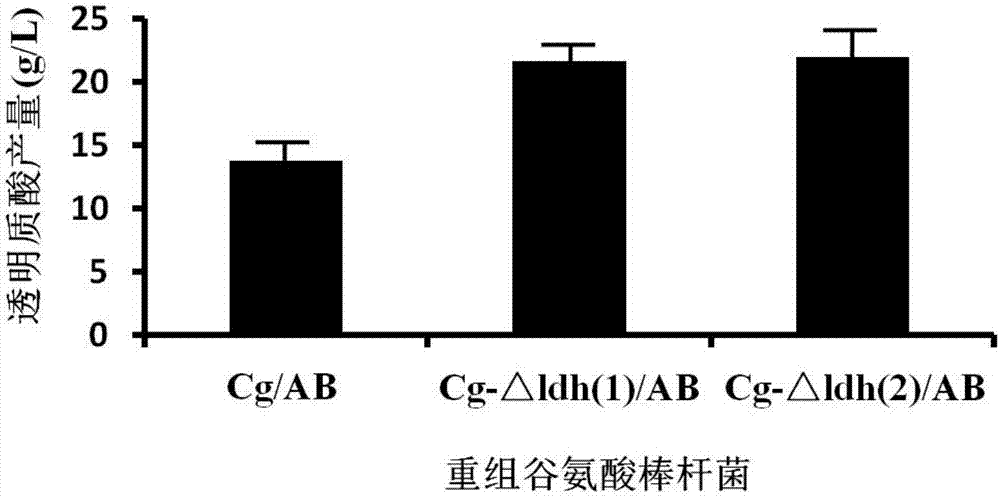

[0090] Example 3: Using Cg-△ldh(1) and Cg-△ldh(2) as hosts to construct recombinant strains producing hyaluronic acid

[0091] Plasmid pXMJ19-A carrying hasA (refer to patent CN103937734A for its construction), plasmid pXMJ19-AB carrying hasA and hasB (refer to patent CN103937734A for its construction), plasmid pXMJ19-AC carrying hasA and hasC, carrying hasA and Plasmid pXMJ19-AD with hasD, plasmid pXMJ19-AE with hasA and hasE, plasmid pXMJ19-ABC with hasA, hasB and hasC (for its construction refer to patent CN103937734A), plasmid pXMJ19-ABD with hasA, hasB and hasD and carrying the plasmid pXMJ19-ABE with hasA, hasB and hasE, the recombinant ldh knockout strains Cg-△ldh (1) and Cg-△ldh (2 )middle.

[0092] Among them, hasA is hyaluronic acid synthase gene, hasB is UDP-glucose dehydrogenase gene, hasC is UDP-glucose pyrophosphorylase gene, hasD is glucosamine uridine transferase gene, hasE is phosphoglucose mutase gene .

[0093] The construction of the above plasmids pXMJ1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com