Chip removing machining cutter, cutting board clamping blades and replaceable blade

A technology of cutting inserts and tools, applied in cutting inserts, tool holders, accessories of tool holders, etc., can solve the problem of not effectively reaching the rake face of cutting inserts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

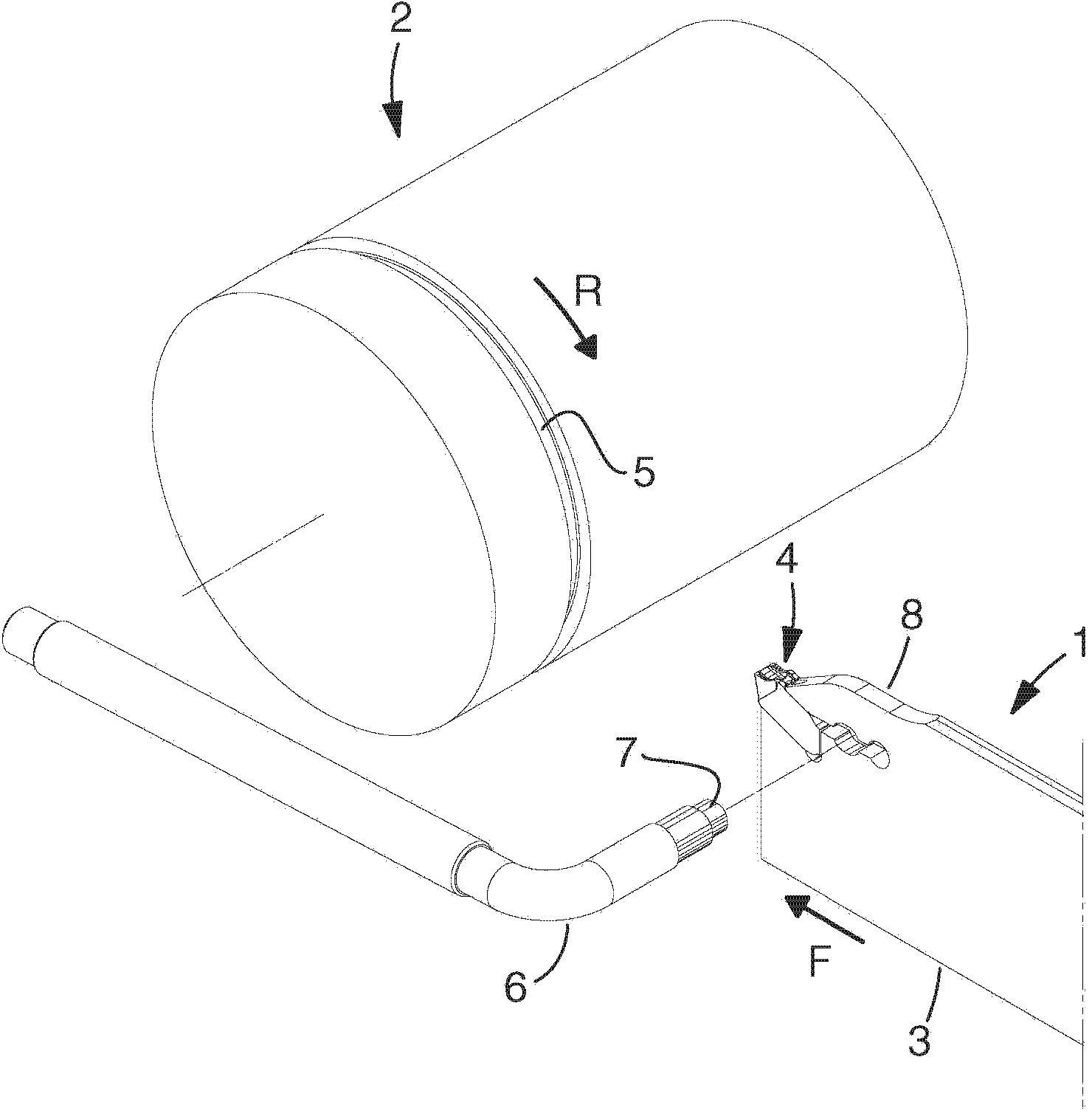

[0035] exist figure 1 In , a tool 1 according to the invention is shown in connection with the machining of a workpiece 2 . The tool is realized in the form of a turning tool, the main part of which is the blade plate 3 which serves as a holder or base body for an exchangeable cutting insert 4 . The workpiece 2 is cylindrical and rotatable in the direction of rotation R. As shown in FIG. By feeding the tool 1 longitudinally in the feed direction F during simultaneous rotation of the workpiece, a circumferential groove 5 can be provided in the envelope surface of the workpiece, the width of which is determined by the width of the main cutting edge comprised in the cutting insert 4 , while the depth of the groove 5 is determined by how far the blade and its cutting inserts are fed into the workpiece.

[0036] figure 1 The processing method illustrated in is a grooving operation.

[0037] exist figure 1 , also shows a key 6 with an eccentric body 7 by means of which a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com