lens

A lens and lens barrel technology, applied in the lens field, can solve problems such as lens group deviation and lens imaging influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

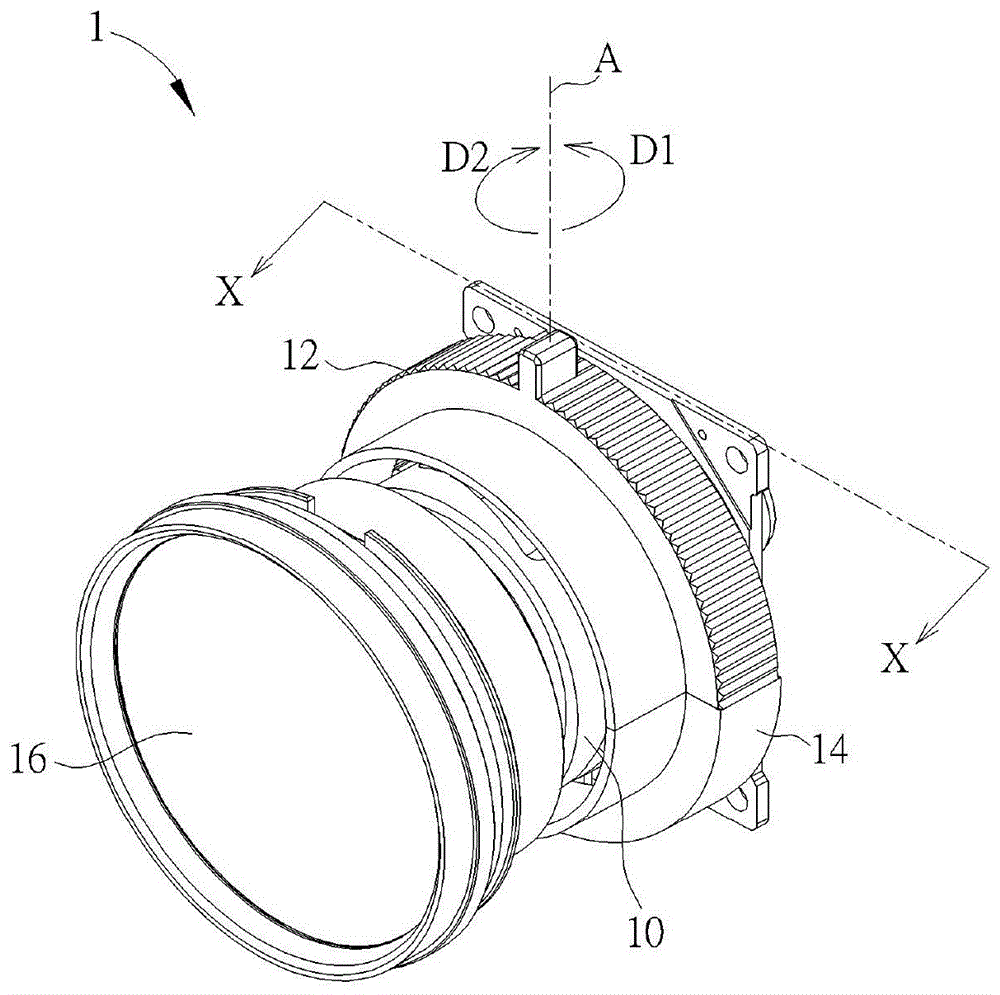

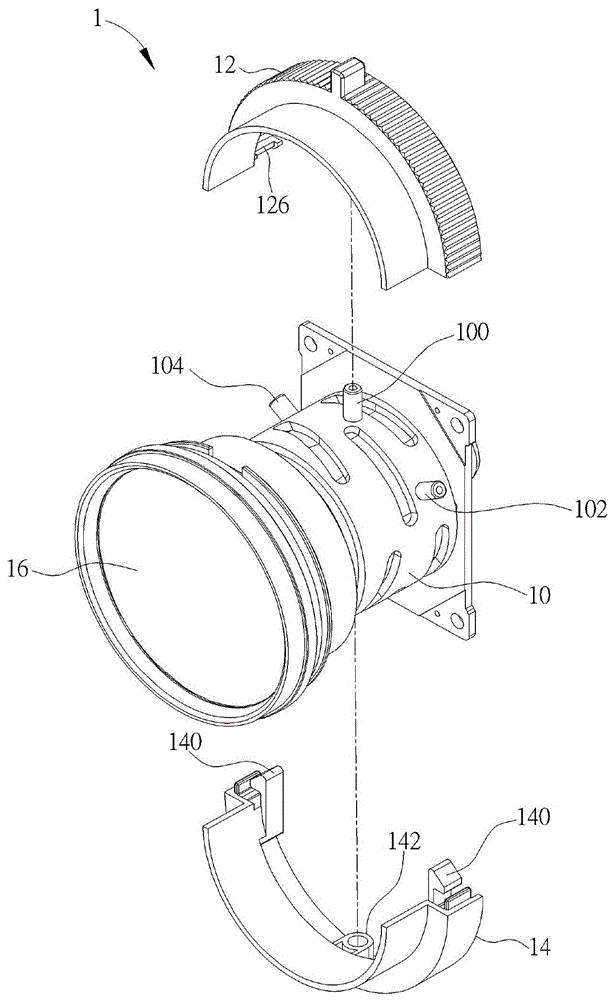

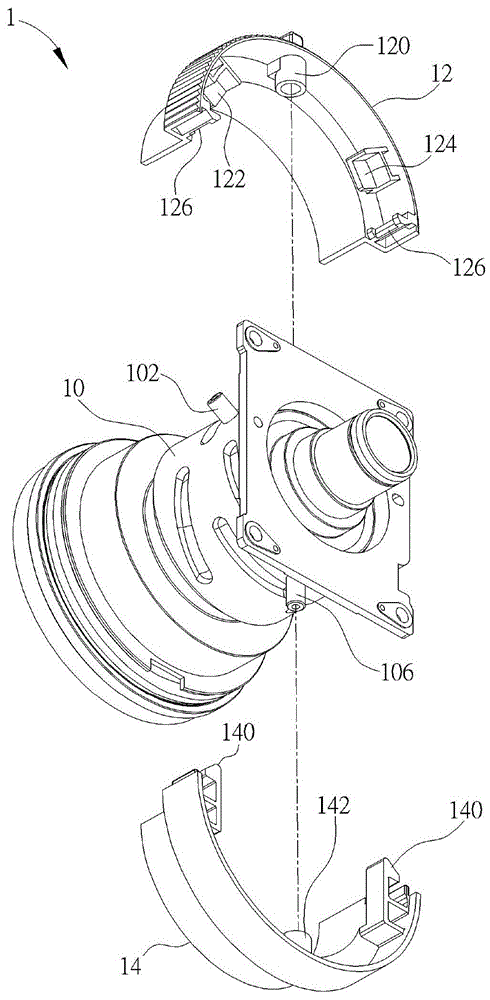

[0021] see Figure 1 to Figure 4 , figure 1 is a perspective view of a lens 1 according to an embodiment of the present invention, figure 2 for figure 1 Exploded view of lens 1 in, image 3 for figure 1 Exploded view of lens 1 in another perspective, Figure 4 for figure 1 The sectional view of the lens 1 along the line X-X in .

[0022] Such as Figure 1 to Figure 4 As shown, the lens 1 includes a lens barrel 10 , a first swivel 12 and a second swivel 14 . The lens 1 can be applied to cameras, projectors or other electronic devices with imaging functions, depending on the actual application. In practical applications, the lens barrel 10 is provided with a lens group 16 for imaging. The lens barrel 10 has a first positioning portion 100 , a first protruding portion 102 and a second protruding portion 104 , wherein the first protruding portion 102 and the second protruding portion 104 are located on two sides of the first positioning portion 100 . The first swivel 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com