washing machine

A cleaning machine and cleaning mechanism technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low manual cleaning efficiency, hidden safety hazards in manual cleaning, low mechanical cleaning efficiency, etc., and achieve saving manpower, reduce production costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

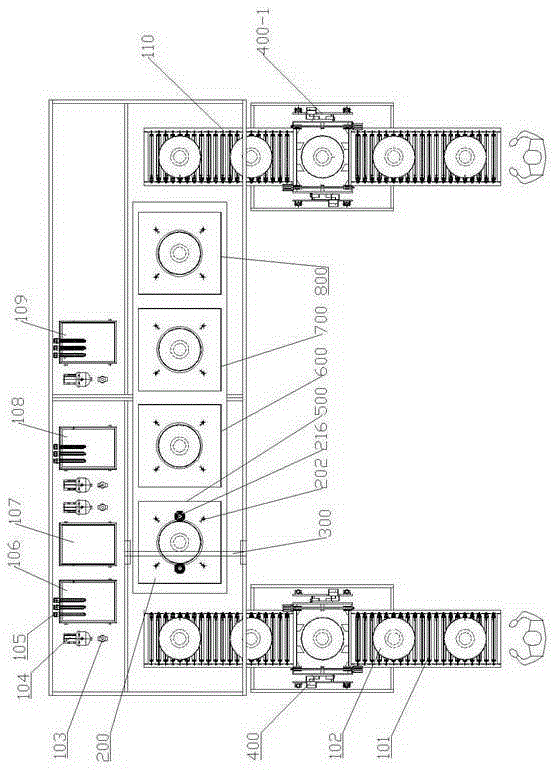

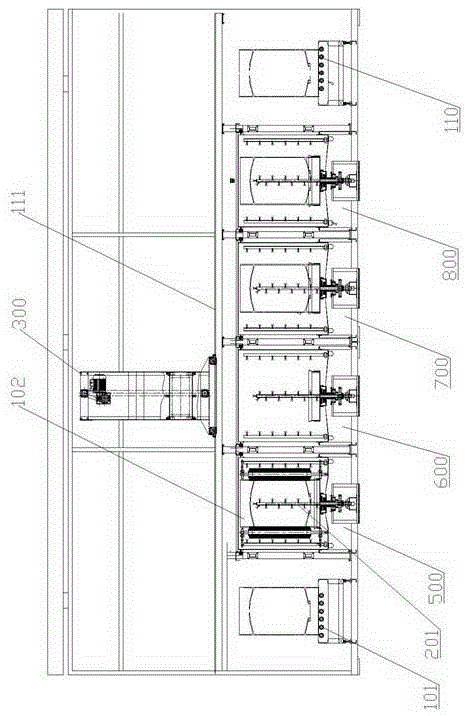

[0046] Embodiment 1: a kind of washing machine, see Figure 1 to Figure 13 , the cleaning machine mainly includes a frame, a barrel feeding mechanism, a rotating cleaning mechanism 200, and a barrel discharging mechanism correspondingly arranged on the frame in turn.

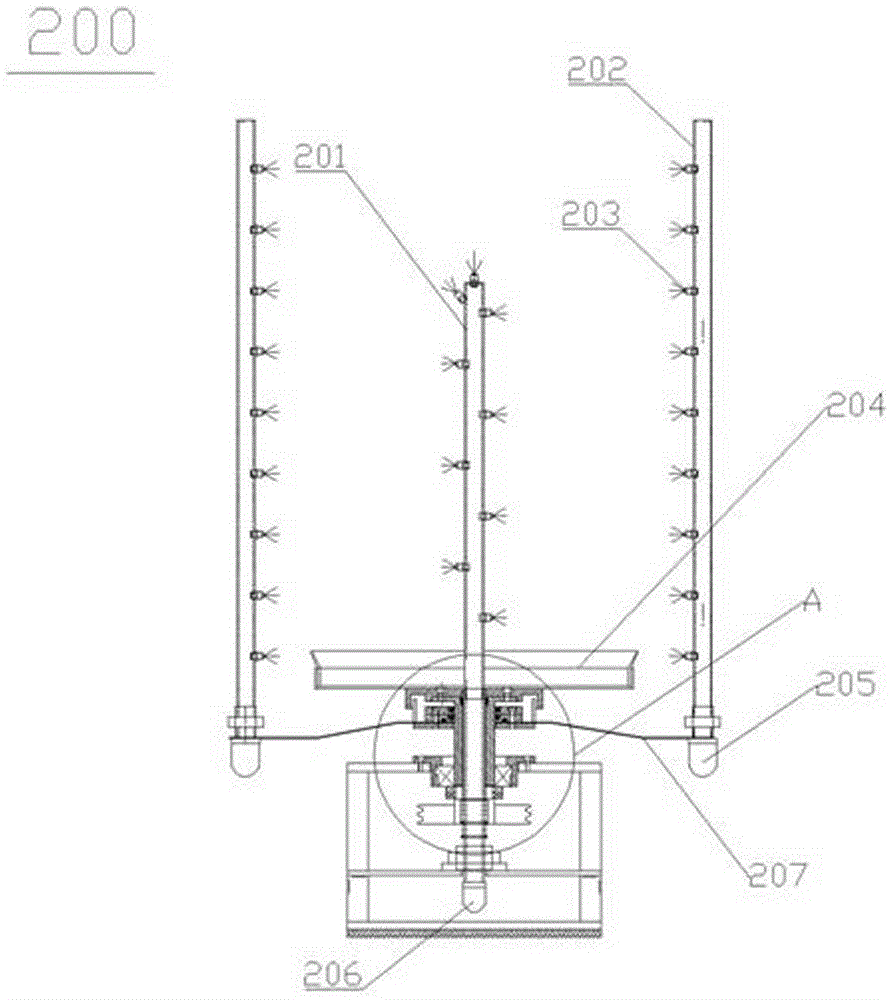

[0047] The rotary cleaning mechanism 200 includes a rotatable placement tray 204, a through hole is opened in the middle of the placement tray, and an inner cleaning pipe 201 correspondingly connected with a cleaning solution supply source is provided above the placement tray 204, along the Two outer cleaning pipes 202 correspondingly connected with the cleaning liquid supply source are arranged around the placement tray, and a plurality of nozzles 203 are arranged on the inner cleaning pipe 201 and the outer cleaning pipe 202; the rotating cleaning mechanism The 200 also includes a rotating member 212 correspondingly arranged under the placement tray 204 and having a through hole therein, and a driving wheel 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com